Resource utilization method of oil sludge

A technology of recycling and sludge, applied in the field of resource science and technology, can solve the problems of harmful substances in waste and single sludge treatment, and achieve the effect of simplifying the recycling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

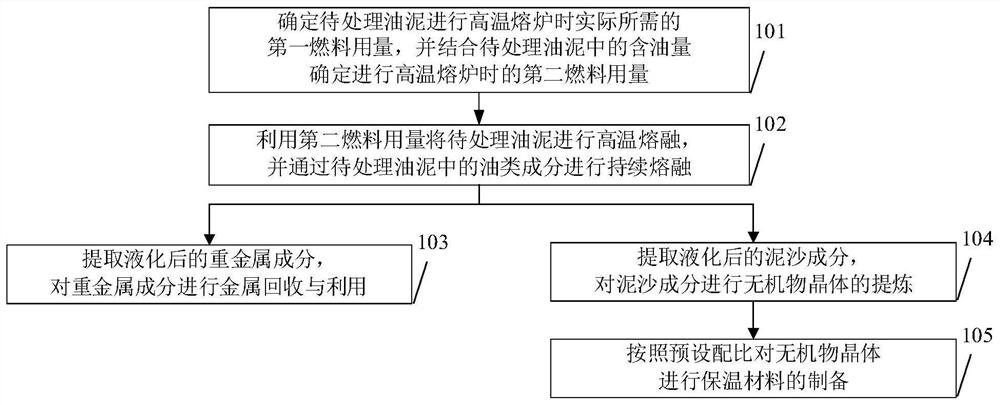

[0034] Please refer to figure 1 , which shows a flowchart of a method for resource utilization of oil sludge shown in an exemplary embodiment of the present application. The method includes:

[0035] Step 101: Determine the first fuel consumption actually required when the sludge to be treated is put into a high-temperature furnace, and determine the second fuel consumption when the sludge to be treated is used in a high-temperature furnace in combination with the oil content in the sludge to be treated.

[0036] Wherein, the second fuel consumption is lower than the first fuel consumption. In the traditional oil sludge treatment method, the main focus is on the extraction of the oil components in the oil sludge. When the extracted oil components are used in other industrial operations, in fact, the process of extracting the oil components also requires high temperature conditions, and still requires additional consumption. fuel (i.e. the first fuel consumption); and the app...

Embodiment 2

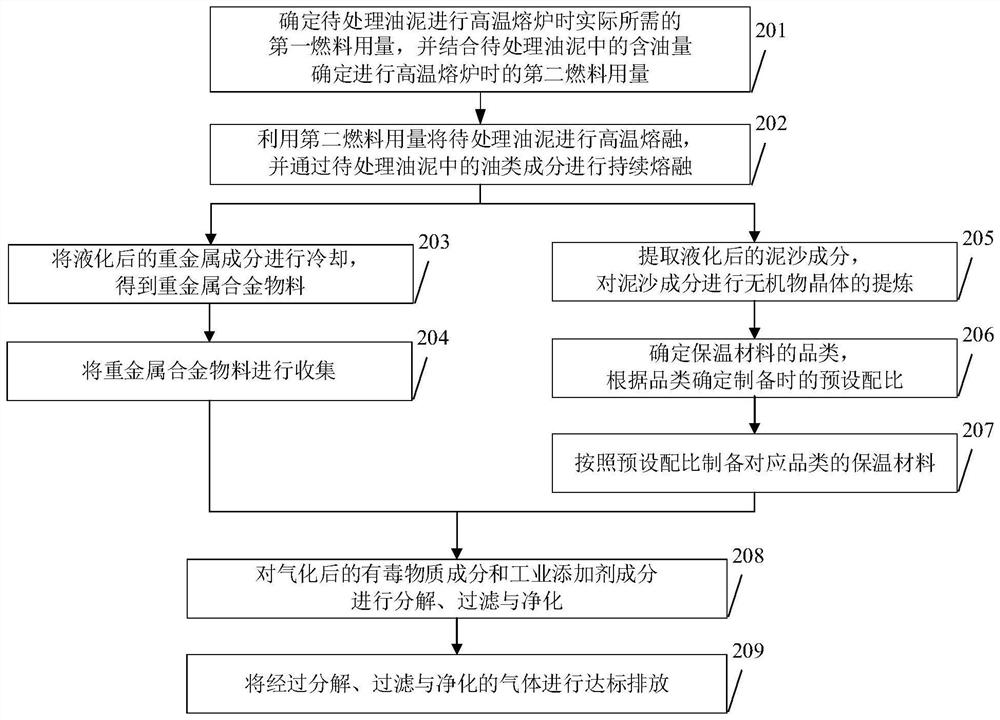

[0045] Please refer to figure 2 , which shows a flowchart of a method for resource utilization of oil sludge shown in another exemplary embodiment of the present application. The method includes:

[0046] Step 201, determine the actual required first fuel consumption when the sludge to be treated is put into a high-temperature furnace, and determine the second fuel consumption when the high-temperature furnace is used in combination with the oil content in the sludge to be treated.

[0047] For this step, please refer to step 101, which will not be repeated here in this embodiment.

[0048] Step 202, using the second amount of fuel to melt the oil sludge to be treated at high temperature, and continue melting through the oil components in the oil sludge to be treated.

[0049]For this step, please refer to step 102, which will not be repeated here in this embodiment. Among them, the temperature condition at the time of high-temperature melting is 1350-1800°C.

[0050] Ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap