Multifunctional coating device for coated glass production

A technology of coating glass and coating device, which is applied in the field of coating devices for the production of multi-functional coated glass, can solve the problems of substrate coating of different widths, large energy consumption, excessive heat dissipation, etc., and achieves reduction of energy consumption and dissipation. The effect of speed and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

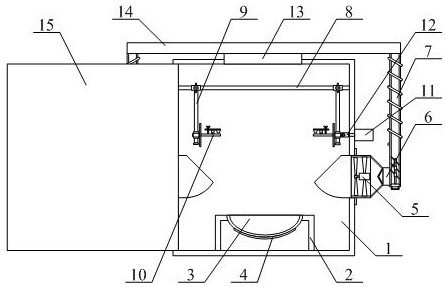

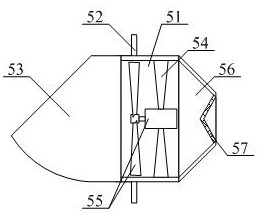

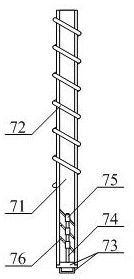

[0034] as attached figure 1 And attached figure 2As shown, a coating device for the production of multifunctional coated glass includes a sealed box 1, a support frame 2, an evaporating dish 3, an electric heating plate 4, a coating baking frame structure 5, a connecting pipe 6, and a heating intake frame structure 7 , crossbar 8, width adjustment frame structure 9, substrate clamping frame structure 10, rotating motor 11, sleeve 12, air outlet pipe 13, cross pipe 14 and box door 15, and described support frame 2 bolts are connected in sealed box The lower part of the inside of the body 1; the evaporating dish 3 is embedded in the middle of the support frame 2; the electric heating plate 4 is screwed to the lower part of the evaporating dish 3; the coating baking frame structure 5 is respectively installed on The left and right sides of the middle position of the sealed box body 1; the connecting pipe 6 is arranged on the side of the coating baking frame structure 5 away fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com