Phase-change energy-saving window with ventilation function

An energy-saving window and functional phase technology, applied in the field of windows, can solve the problems of phase change materials such as long heat storage and heat release time, low thermal conductivity, and single function of glass windows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

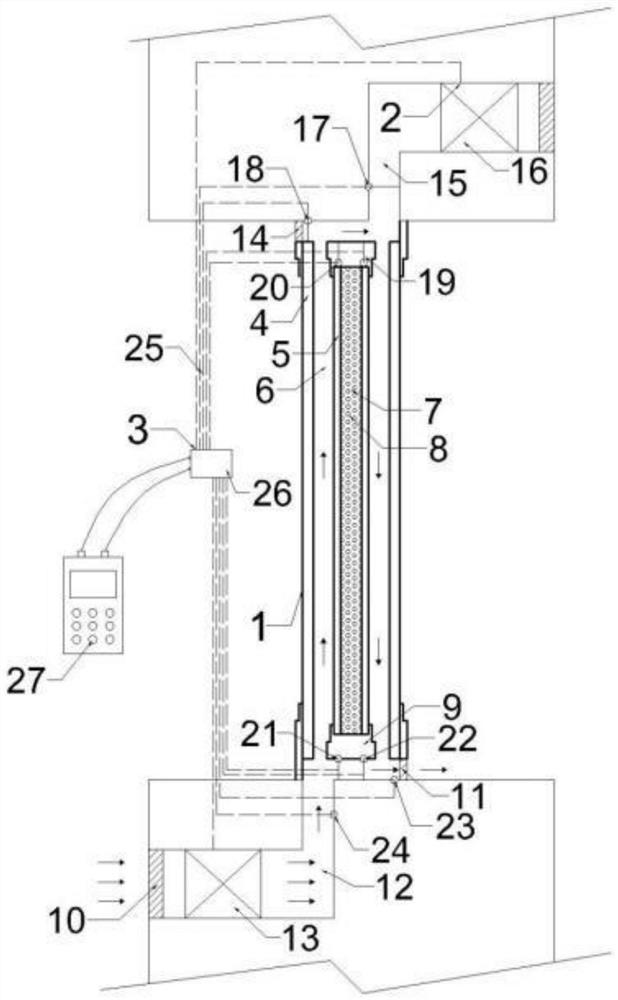

[0038] Embodiment 1, fresh air preheating

[0039] refer to figure 1 , this mode is used in sunny days when the design temperature of the room is higher than the outdoor temperature, and there are high requirements for the air quality of the room. The fresh air preheating mode is selected on the control panel 27, and now the control panel 27 adjusts the opening of the fresh air blower 13 and the rotation of the air pipe valve. Valve 17 and valve 23 are rotated to horizontal 0°, valve 18 and valve 24 are rotated to vertical 90°, valve 19 and valve 20 are kept vertical at 90°, placed in the groove of window frame 9 to facilitate gas circulation, valve 21 Maintain a vertical 90° with the valve 22 and rise from the bottom of the groove of the window frame 9 to the top of the groove for cutting off the air duct. The gas is inhaled from the air inlet 10 under the action of the fresh air fan 13, enters the fresh air duct 12, flows through the first air layer 6, and then flows throu...

Embodiment 2

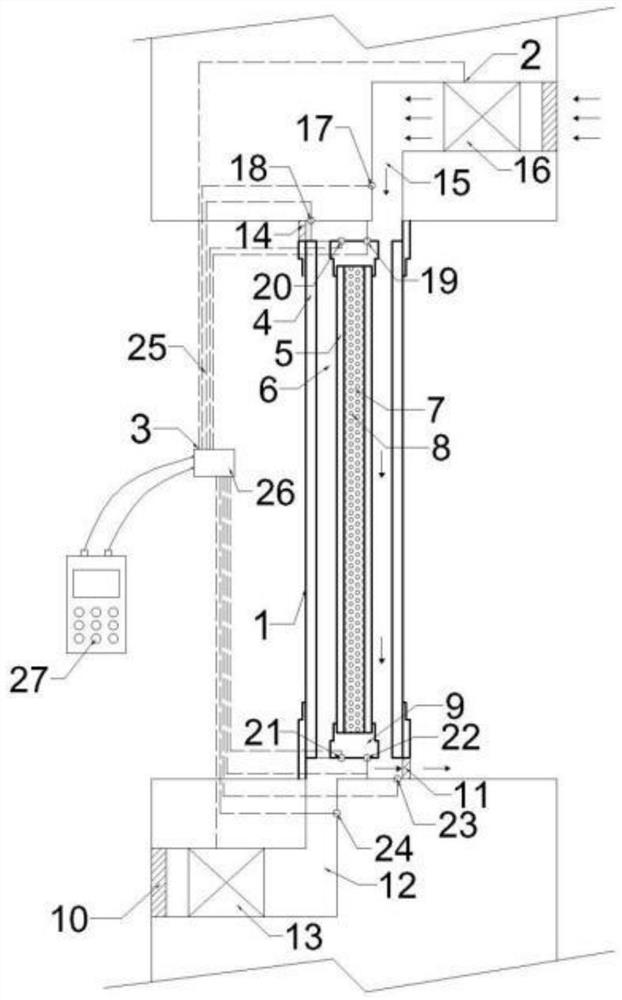

[0040] Embodiment 2, internal circulation heating

[0041] Such as figure 2 As shown, this mode is used when the design temperature of the room is higher than the outdoor temperature on a sunny day, and there is no requirement for fresh air in the room, and the room air self-circulation method is used for heating. Select the internal circulation heating mode on the control panel 27. At this time, the control panel 27 adjusts the opening of the exhaust fan 14 and the rotation of the air pipe valve. The valve one 17 and the valve two 18 are rotated to a vertical 90°, and the valve seven 23 and the valve eight 24 are rotated to the horizontal 0°, valve three 19, valve four 20, valve five 21 and valve six 22 rise from the bottom of the window frame 9 groove to the top of the groove, valve three 19 and valve six 22 maintain a vertical 90°, valve four 20 and valve Five 21 rotates to level 0 °, cuts off the connection of the first air layer 6 and the ventilation duct, and the gas i...

Embodiment 3

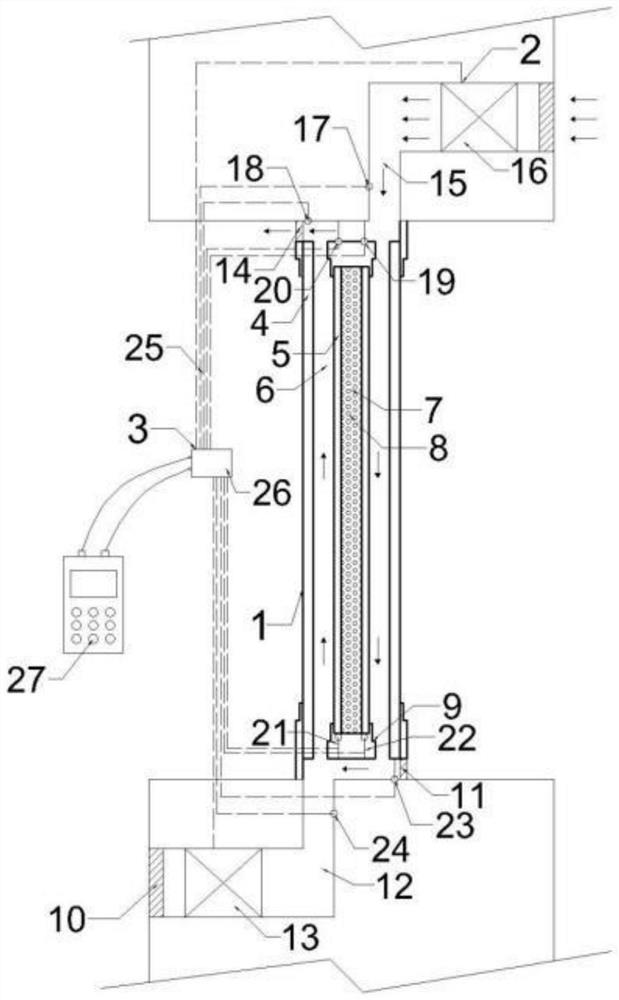

[0042] Embodiment three, ventilation and heat removal

[0043] refer to image 3 , this mode is used when the outdoor temperature is higher than the indoor design temperature, and there are certain requirements for the room air quality. The ventilation and heat exhausting mode is selected on the control panel 27, and now the control panel 27 adjusts the exhaust fan 16 to open. Valve one 17 and valve seven 23 rotate to vertical 90°, valve two 18 and valve eight 24 rotate to horizontal 0°, valve three 19 and valve four 20 maintain vertical 90° from the bottom of the window frame 9 groove upward to the concave The top of the groove is used to cut off the air duct, and the valve five 21 and the valve six 22 maintain 90°, as in the window frame 9 grooves, it is convenient for gas circulation. The gas is sucked from the air inlet 10 under the action of the exhaust fan 16, enters the exhaust duct 15, flows through the second air layer, and then flows through the first air layer 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com