Liquid CO2 logging spacer fluid presetting process

A spacer fluid and liquid technology, applied in wellbore/well components, measurement, earthwork drilling and production, etc., can solve problems such as failure of logging instruments to go into the well, logging failure, etc., to improve logging efficiency and safety, and facilitate transportation , high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The implementation process of the method of the present invention will be described below as an example.

[0026] a liquid CO 2 The logging spacer fluid presetting process includes the following steps:

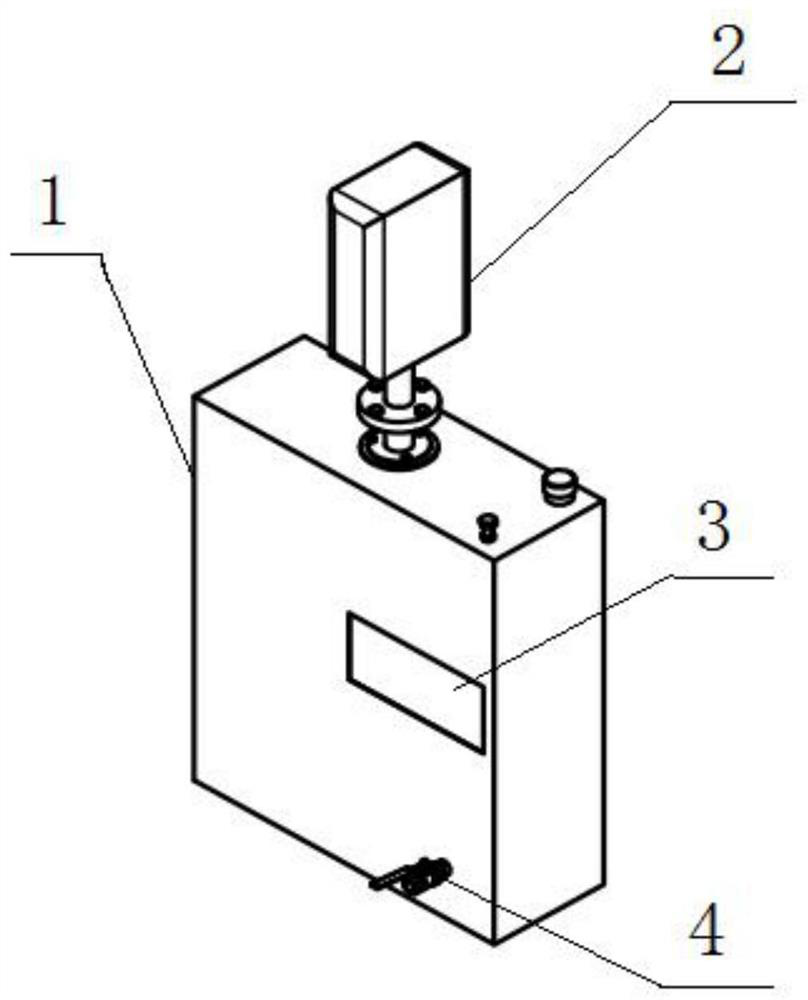

[0027] The first step: prepare and install the spacer fluid preset device, the spacer fluid preset device includes the spacer fluid box 1, the top of the spacer fluid box 1 is equipped with a high-pressure grease injection pump 2; the upper part of the spacer fluid box 1 has a liquid level Hole 3, the safe height of the liquid level in the monitoring tank; the lower part is equipped with a liquid discharge valve 4; the high-pressure grease injection pump is connected to the pre-set port of the spacer fluid on the wellhead sealing device through the spacer liquid high-pressure pipeline; the high-pressure grease injection pump is composed of a pneumatic pump and a The plunger pump is composed of two parts. The pneumatic pump uses compressed air as the power to reciprocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com