Tunnel tunneling device and tunneling machine

A technology for tunneling and boring machines, applied in tunnels, mining equipment, earth-moving drilling, etc., can solve the problems of difficulty in timely application of initial support, many disturbances of surrounding rock, and low degree of mechanization, so as to reduce potential safety hazards, Good molding effect and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

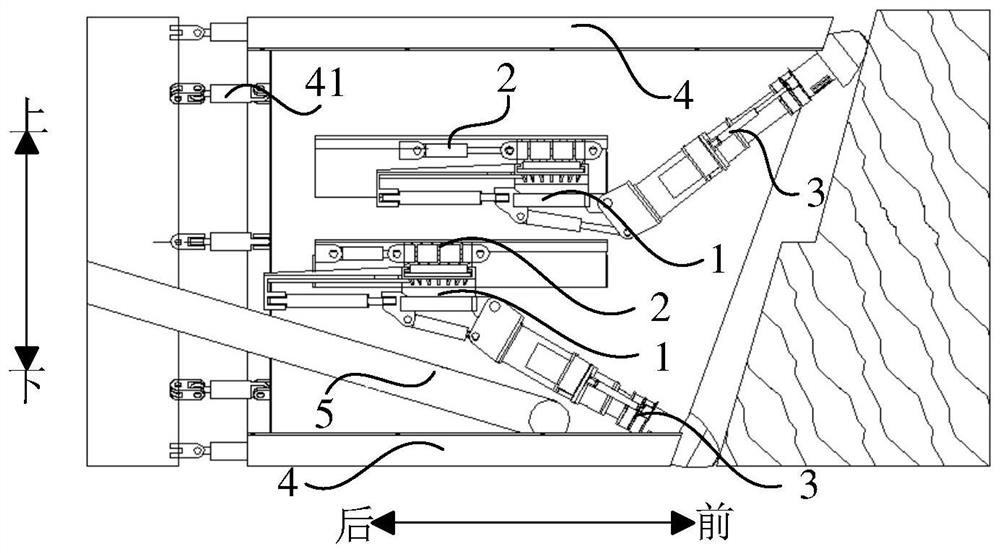

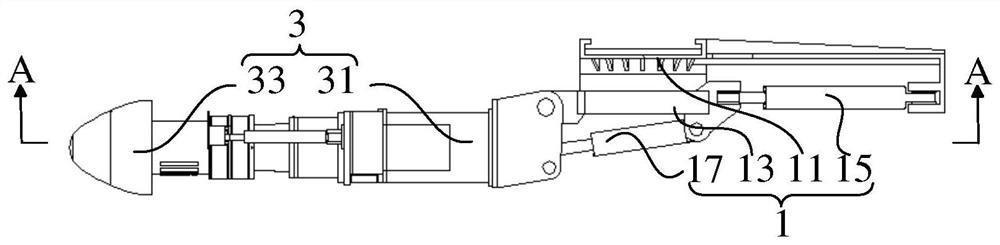

[0035] Such as figure 1 As shown, the tunnel boring device includes: two rotary devices 1, two telescopic mechanisms 2 and two cutting devices 3, wherein the two rotary devices 1 are respectively hinged to two cutting devices 3; the two telescopic mechanisms 2 are respectively connected to the two The two rotary devices 1 are connected in one-to-one correspondence. When the tunnel boring machine does not move forward and backward, the telescopic mechanism 2 can drive the rotary device 1 to move along the front and rear directions of the tunnel, thereby causing a front-rear displacement difference between the two cutting devices 3. , so that the two cutting devices 3 can carry out multi-section excavation, which is suitable for tunnel excavation by the step method, and excavates the face of the tunnel into a step shape.

[0036]Specifically, the tunnel boring device provided in this embodiment is provided with two slewing devices 1 , and the two slewing devices 1 are arranged i...

Embodiment 2

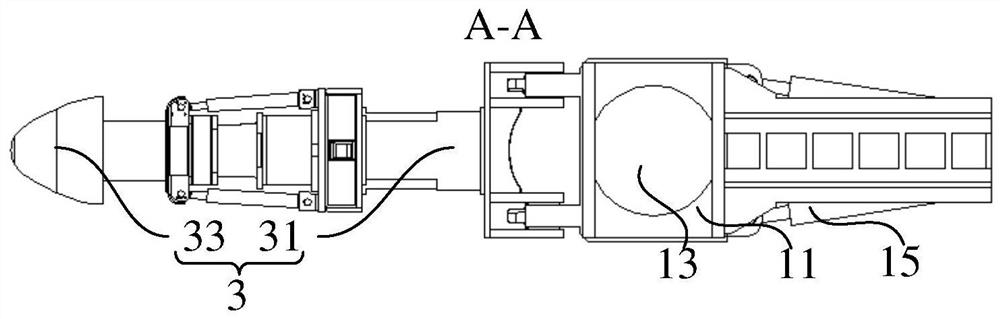

[0043] On the basis of Example 1, as Figure 4 and Figure 5 As shown, further, the telescopic mechanism 2 includes a sliding platform 21 extending forward and backward in the horizontal direction, a telescopic oil cylinder 25 and a connecting frame body 23 slidingly connected with the sliding platform 21; the rotary device 1 is arranged on the connecting frame body 23; Both ends of the oil cylinder 25 are respectively connected with the sliding platform 21 and the connecting frame body 23 for driving the connecting frame body 23 to reciprocate along the extending direction of the sliding platform 21 .

[0044] The telescopic mechanism 2 includes a sliding platform 21 , a telescopic oil cylinder 25 and a connecting frame body 23 . The upper and lower rotary devices 1 are respectively provided with upper and lower two-layer sliding platforms 21. One end of the telescopic oil cylinder 25 is connected to the sliding platform 21, and the other end of the telescopic oil cylinder 2...

Embodiment 3

[0046] On the basis of embodiment one or embodiment two, such as Figure 4 and Figure 5 As shown, further, the connecting frame body 23 extends along the length direction perpendicular to the sliding platform 21 in the horizontal direction; a sliding mechanism 27 is provided between the connecting frame body 23 and the turning device 1; the sliding mechanism 27 includes a driving member and a sliding Components; the rotary device 1 is slidably connected with the connecting frame through the sliding part, and moves along the extension direction of the connecting frame body 23 under the drive of the driving mechanism.

[0047] The tunnel boring device provided in this embodiment enables the rotary device 1 to move left and right on the basis of being able to move forward and backward, so that the rotary device 1 can move to any horizontal position, so that the tunnel face of a long-span tunnel can be excavated. Excavation. For example, the face of the upper floor is divided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com