Preparation method of anisotropic samarium-cobalt magnetic powder

An anisotropic, samarium cobalt technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of samarium cobalt particles cracking without breaking, difficulty in hydrogen absorption, and low hydrogen absorption characteristics of samarium cobalt , to achieve the effect of uniform hydrogen absorption and high degree of orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of anisotropic samarium cobalt magnetic powder in this embodiment is as follows:

[0059] (1) Melting and casting: The samarium-cobalt cast sheet is made by the quick-setting process, and the molecular formula of the samarium-cobalt alloy is Sm(Co bal Fe 0.25 Cu 0.06 Zr 0.02 Si 0.01 Ti 0.01 ) 7.8 , the quick-setting process adopts a copper roller cooling process, the linear speed of the copper roller is 0.5m / s, and the thickness of the samarium cobalt cast sheet is 0.8mm;

[0060] (2) Aging treatment: Place the samarium-cobalt cast piece in an inert gas environment, keep it at 830°C for 20h, then cool slowly to 400°C at a rate of 0.7°C / min and hold it for 5h, and finally at a rate of 50°C / min Cool to room temperature;

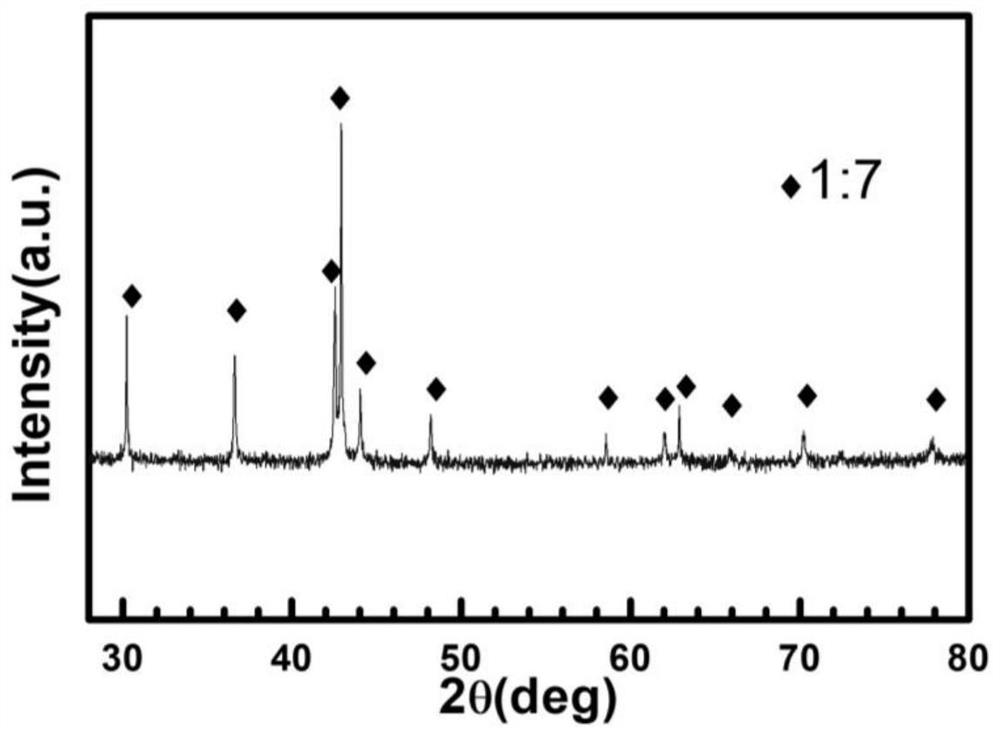

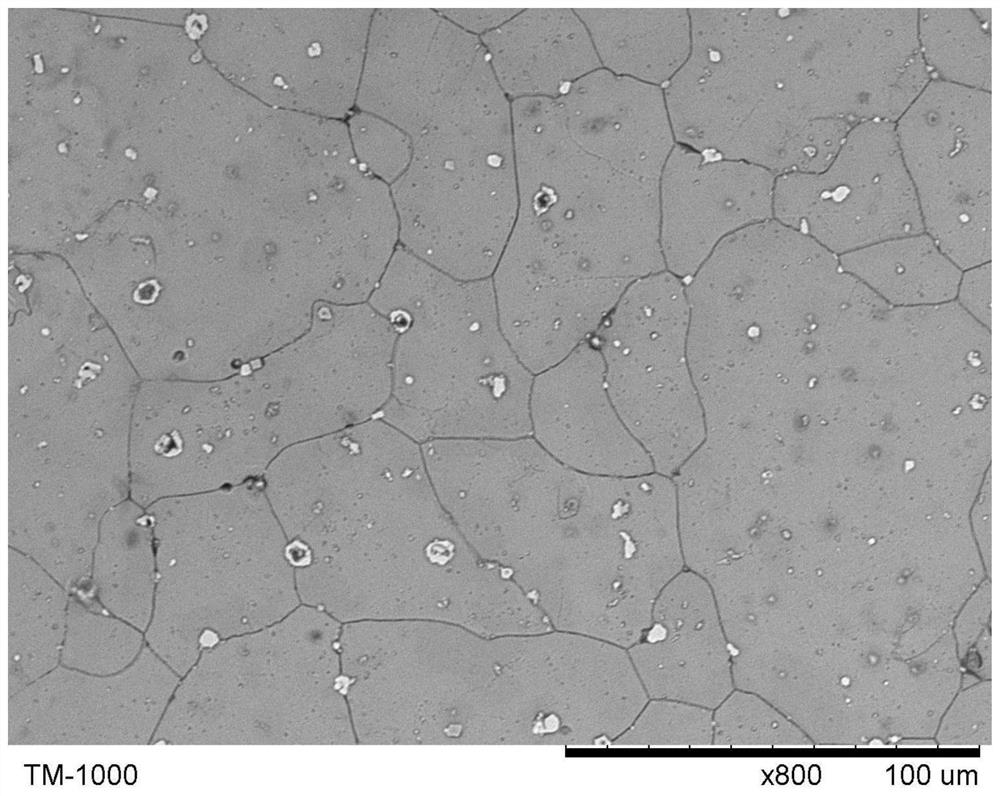

[0061] (3) Powder making: first place the samarium cobalt cast piece in a hydrogen absorbing device with a capacity of 300kg, put small steel balls with a weight of 100g / piece in the hydrogen absorbing device, the total weig...

Embodiment 2

[0063] The preparation method of anisotropic samarium cobalt magnetic powder in this embodiment is as follows:

[0064] (1) Melting and casting: The samarium-cobalt cast sheet is made by the quick-setting process, and the molecular formula of the samarium-cobalt alloy is Sm(Co bal Fe 0.20 mn 0.05 Cu 0.06 Zr 0.02 Ga 0.01 f 0.01 ) 7.4 , the quick-setting process adopts a copper roller cooling process, the linear speed of the copper roller is 0.5m / s, and the thickness of the samarium cobalt cast sheet is 0.8mm;

[0065] (2) Aging treatment: Place the samarium cobalt cast piece in an inert gas environment, keep it at 830°C for 25h, then slowly cool it to 400°C at a rate of 0.5°C / min and hold it for 5h, and finally at a rate of 50°C / min Cool to room temperature;

[0066] (3) Powder making: first place the samarium cobalt cast piece in a hydrogen absorbing device with a capacity of 300kg, put small steel balls with a weight of 100g / piece in the hydrogen absorbing device, the...

Embodiment 3

[0068] The preparation method of anisotropic samarium cobalt magnetic powder in this embodiment is as follows:

[0069] (1) Melting and casting: the samarium-cobalt cast sheet is made by the quick-setting process, and the molecular formula of the samarium-cobalt alloy is (Sm 0.8 Ce 0.2 )(Co bal Fe 0.22 Cu 0.06 Zr 0.02 V 0.01 f 0.01 ) 7.5 , the quick-setting process adopts a copper roller cooling process, the linear speed of the copper roller is 0.5m / s, and the thickness of the samarium cobalt cast sheet is 0.8mm;

[0070] (2) Aging treatment: place the samarium-cobalt cast piece in an inert gas environment, keep it at 830°C for 20h, then cool slowly to 400°C at a rate of 0.5°C / min and hold it for 5h, and finally at a rate of 50°C / min Cool to room temperature;

[0071] (3) Powder making: first place the samarium cobalt cast piece in a hydrogen absorbing device with a capacity of 300kg, put small steel balls with a weight of 200g / piece in the hydrogen absorbing device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com