Alkyd resin production device

A production device and technology of alkyd resin, applied in the direction of feeding device, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems affecting the quality and quality of resin, low work production efficiency, and inability to completely unload, etc., to achieve improvement Quality and quality, beneficial to blanking, less waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

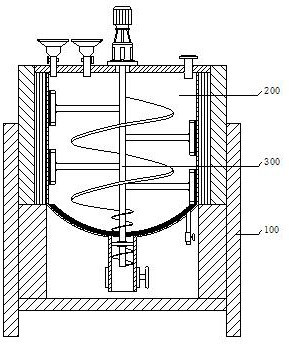

[0038] see figure 1 , the present invention provides a technical solution: an alkyd resin production device, including a bracket 100 , a box body 200 and a blanking assembly 300 .

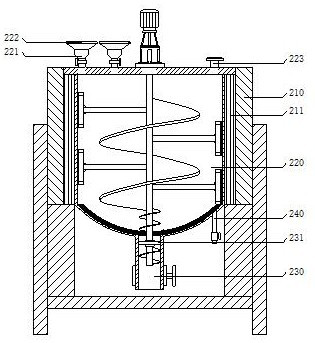

[0039] see figure 2 , the box 200 includes a casing 210, a box body 220 and a feeding pipe 230, the casing 210 is fixedly installed on the bracket 100, the box body 220 is fixedly installed in the casing 210, and the feeding pipe 230 is installed through the bottom of the box body 220, The shell 210 is provided with a heating plate 211. The heating plate 211 is fixedly installed on the side of the shell 210 opposite to the box body 220. It can heat the raw materials, increase the reaction speed, and also keep the finished resin warm to prevent solidification.

[0040] In some specific implementation processes, the top of the box body 220 is provided with an adding bucket 221, at least two adding buckets 221 are provided, and the bottom ends of the two adding buckets 221 communicate with the box b...

Embodiment 2

[0047] see figure 1 , the present invention provides a technical solution: an alkyd resin production device, including a bracket 100 , a box body 200 and a blanking assembly 300 .

[0048] see figure 2 , the box 200 includes a casing 210, a box body 220 and a feeding pipe 230, the casing 210 is fixedly installed on the bracket 100, the box body 220 is fixedly installed in the casing 210, and the feeding pipe 230 is installed through the bottom of the box body 220, The shell 210 is provided with a heating plate 211. The heating plate 211 is fixedly installed on the side of the shell 210 opposite to the box body 220. It can heat the raw materials, increase the reaction speed, and also keep the finished resin warm to prevent solidification.

[0049] In some specific implementation processes, the top of the box body 220 is provided with an adding bucket 221, at least two adding buckets 221 are provided, and the bottom ends of the two adding buckets 221 communicate with the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com