Composite material arc-shaped tooth bevel gear scraping tool

A composite material and arc-shaped tooth technology, applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problems of paired gear noise, expensive machine tools, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

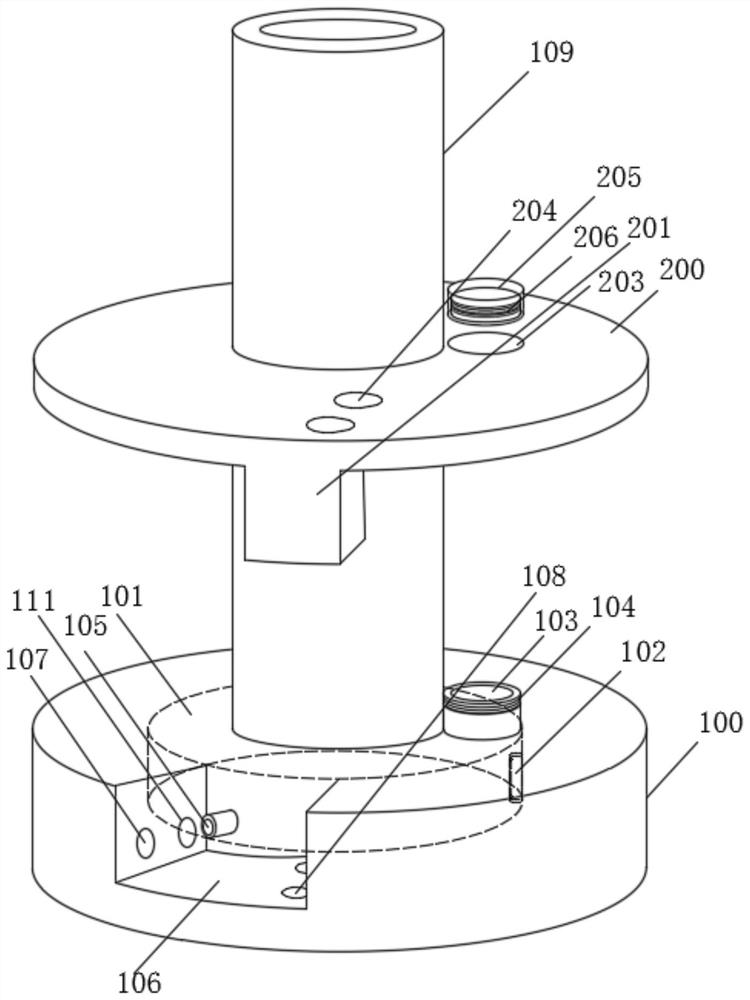

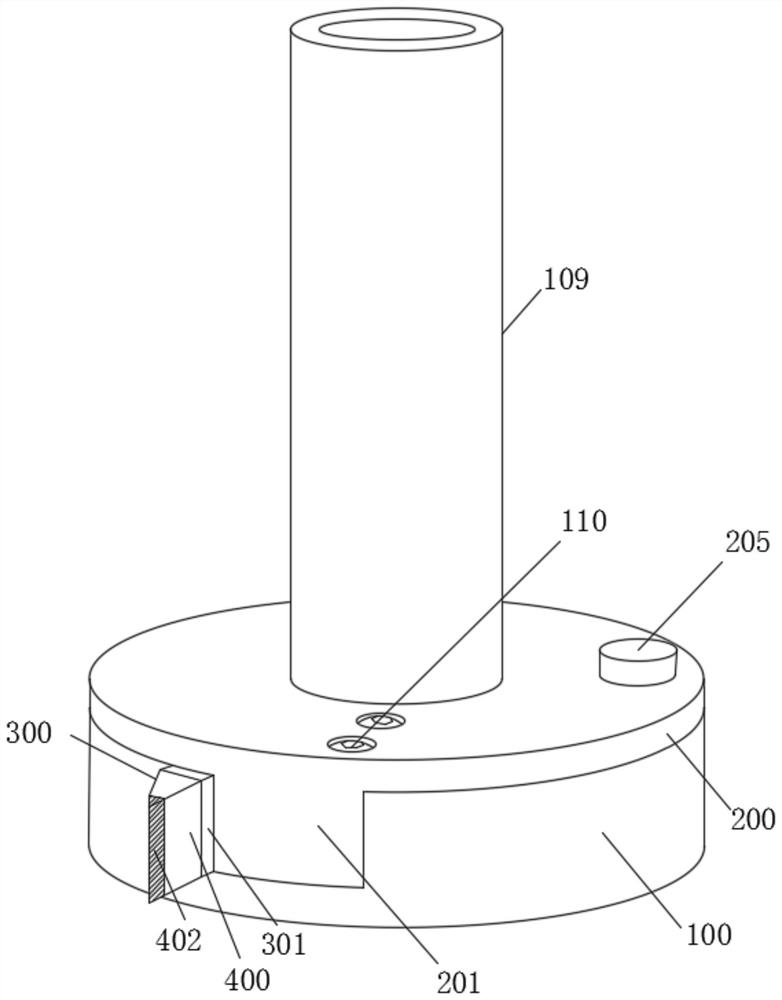

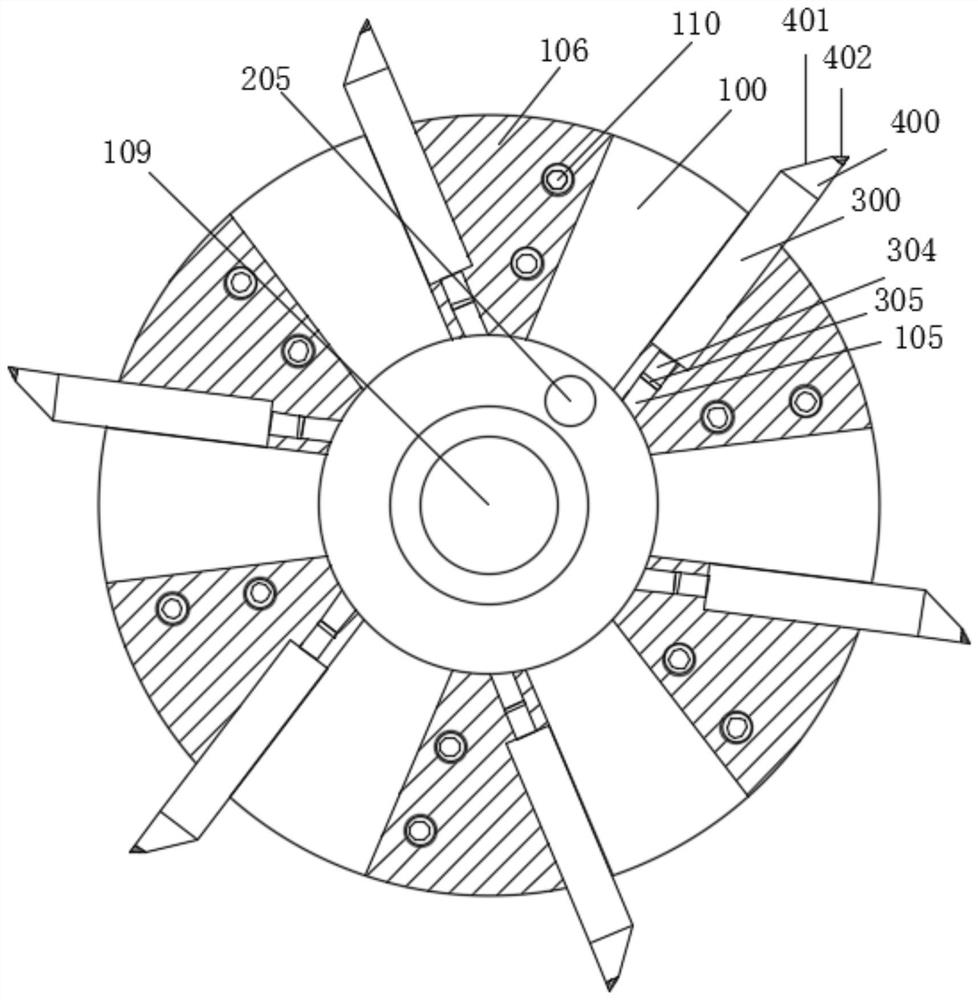

[0039] Refer to attached Figure 1-Figure 8 , a composite material curved bevel gear scraping tool in this embodiment, including a scraper box body 100, a cutter head 200, a knife body 300, a knife head 400, a liquid outlet device 500 and a knife head 2 600, and a scraper box body A coolant box 101 is provided on the inner wall of 100, and the inner wall of one side of the coolant box 101 is fixedly connected to a liquid level sensor 102. A liquid inlet pipe 103 is installed on the top of the coolant box 101, and the outer surface of the liquid inlet pipe 103 is fixedly connected to an external thread 104. One side of 101 is equipped with a liquid outlet pipe 105, and the top of one side of the scraper box body 100 is provided with an arc-shaped opening 106, and one side of the arc-shaped opening 106 is provided with a threaded hole 1 107, and the inner wall of the arc-shaped opening 106 bottom is provided with a threaded hole 2 108, which is arc-shaped. One side of the openin...

Embodiment 2

[0053] Refer to attached Figure 9 , a composite material curved bevel gear scraping tool in this embodiment, including cutter head 2 600 and thin tube 601; specifically, a thin tube 601 is installed on one side of cutter head 2 600, due to inertia and lead block 506 itself The effect of gravity drives the lead weight 506 to the fixed ring 2 503 and throws it out of the inner wall of the liquid outlet device 500. Since the fixed ring 2 503 is provided with a water leakage hole 504, the coolant flows out from the water leakage hole 504 until the blade body 300 is filled. At this time, the heat conducting plate 310 transfers the heat of the cutter head 400 and the outer fixed shell 301 to the heat collecting ring 312. At this time, the coolant contacts the heat collecting ring 312 to cool down the heat collecting ring 312. The cooling liquid will flow from the liquid outlet hole five 409 to the liquid outlet hole four 403, and flow into the two sets of narrow tubes 601 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com