Welding seam allowance of double-welding-seam structure cartridge receiver and machining method

A seam and casing technology, which is applied in the field of welding seam and processing of the double welded seam structure casing, can solve the problems of affecting the quality of welding assembly, inability to assemble, and mutual influence, so as to improve welding quality, assembly efficiency, The effect of improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

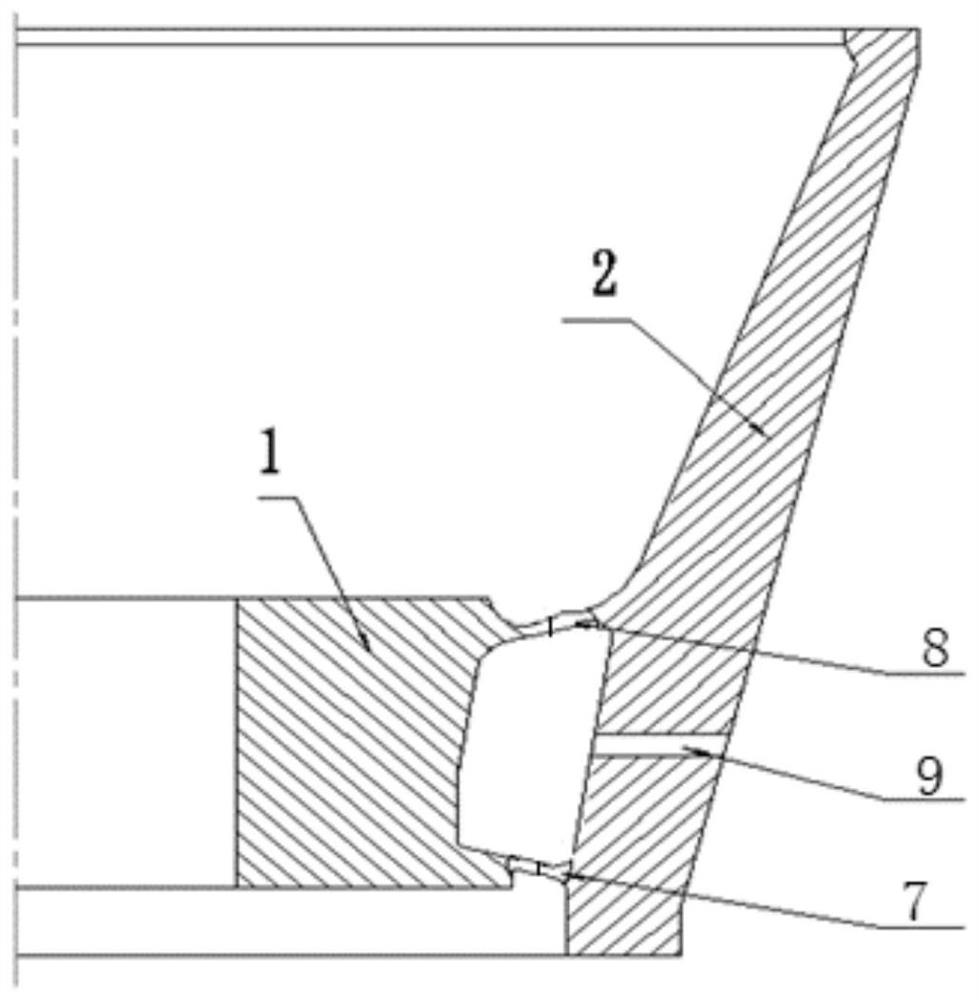

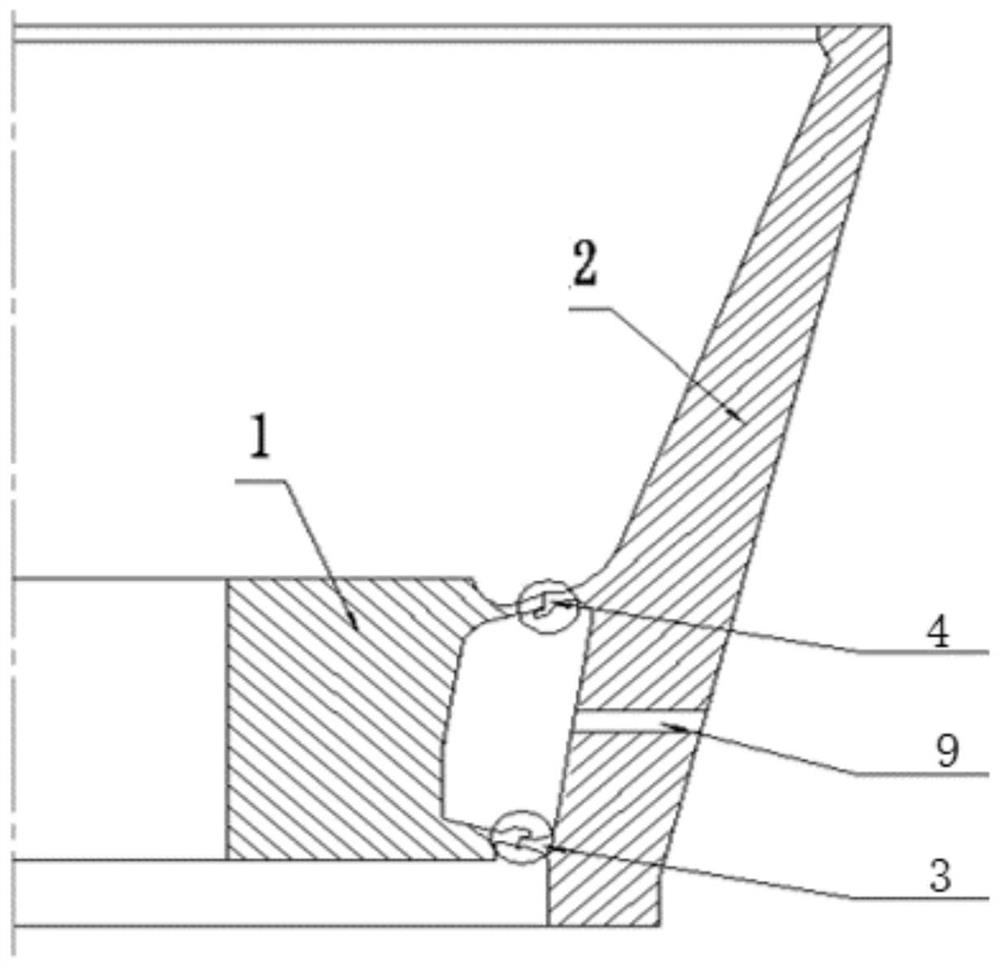

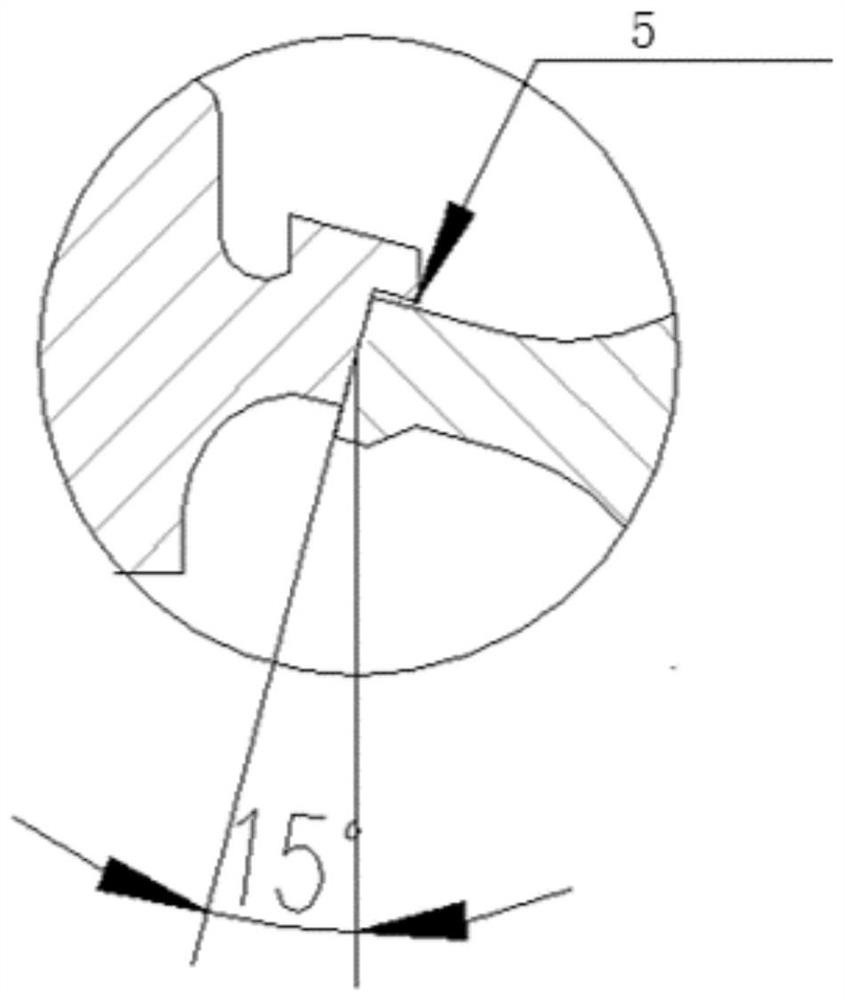

[0053] Taking the diffuser and the casing outside the combustion chamber as examples, the welding seam and processing method of a casing with a double weld seam structure according to the present invention are described.

[0054] The weldment is composed of a diffuser and a combustion chamber. The material of the diffuser and the combustion chamber is GH4169. The inner and outer diameters of the front stop are Ф675.7+0.1mm / Ф675.7-0.1 mm, and the inner and outer diameters of the rear stop are Ф687mm respectively. The disadvantages of the traditional welding seam design and processing method are: 1. Neither of the two welding seams can play a centering role. Due to the roundness error of the inner and outer seams, assembly interference will inevitably occur; 2. There is no design on the bottom edge of the lock The gap structure and the axial size error of the seam will inevitably cause the problem that the axial position cannot be assembled in place; in the process of fitting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com