Flexible deformation brazing filler metal and automatic preparation device and preparation method thereof

A technology for preparing devices and brazing filler metals, which is applied in stirring devices, manufacturing tools, welding equipment, etc., can solve the problems of poor plasticity and poor machinability of brazing filler metals, and achieve good wettability, good ductility, and improved ductility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of flexible deformable solder, its component content is: the content of Bi is 42wt%, the content of In is 2.5wt%, the content of Ag is 0.2wt%, the content of Sn is 55.3wt%; The purity of described Bi is ≥ 99.9%, the purity of In ≥ 99.99%, the purity of Ag ≥ 99.99%, the purity of Sn ≥ 99.999%.

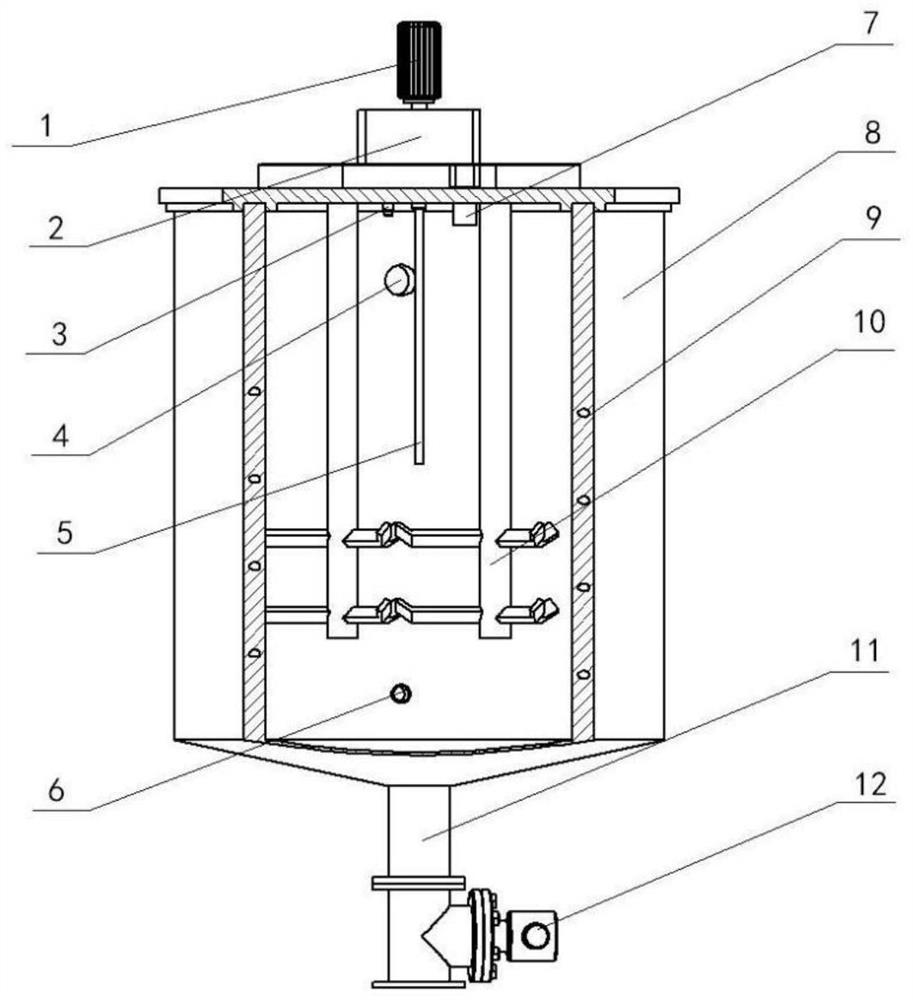

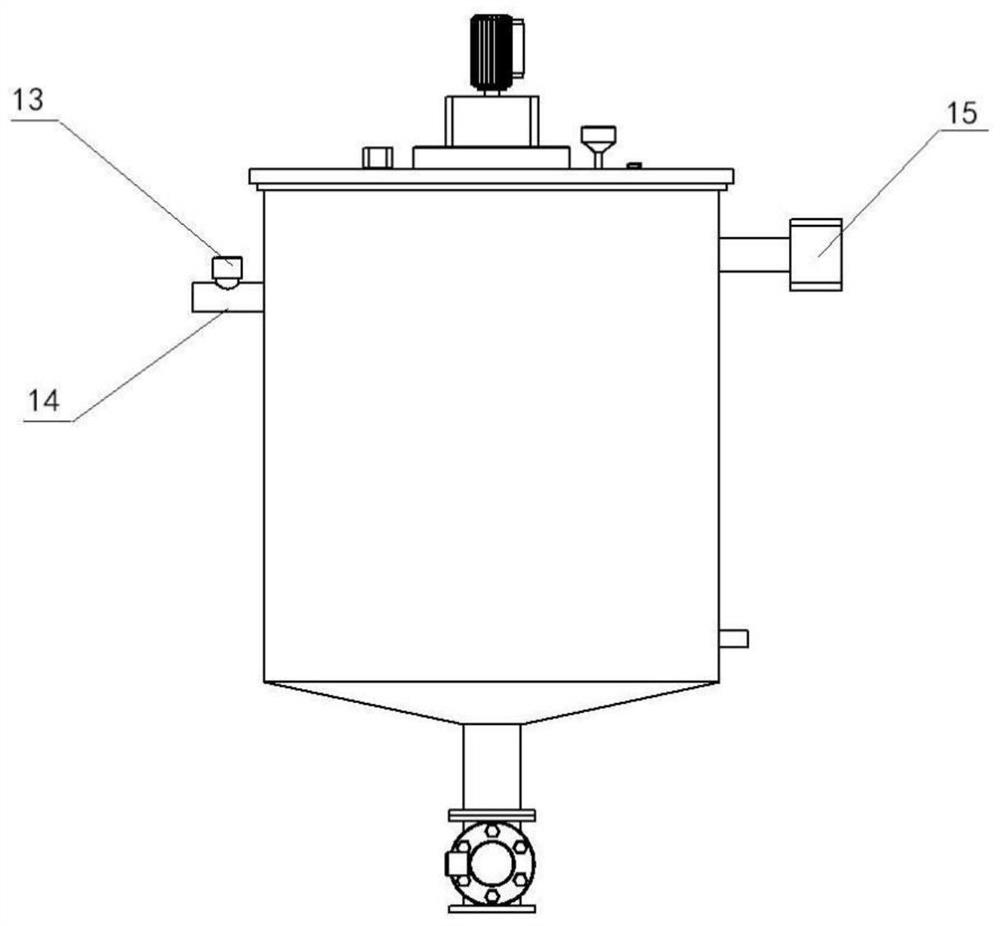

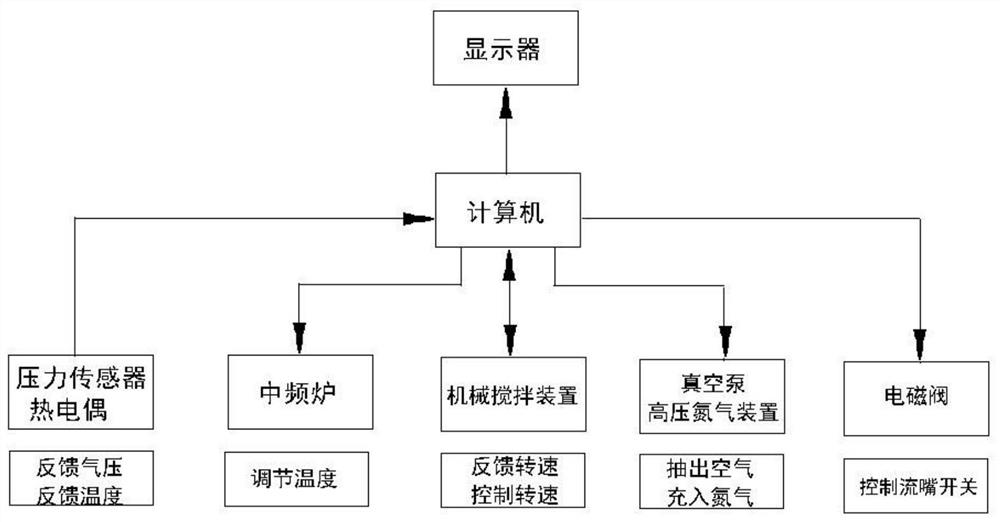

[0031] An automatic preparation device for flexible deformable solder, comprising an intermediate frequency furnace 8, a cover, a vacuum adjustment system and a control system; A flow nozzle 11 is provided at the end, and a solenoid valve 12 connected to the control system is provided on the flow nozzle 11. An inlet pipe 4 and an exhaust pipe 14 are provided on the top of the furnace wall of the intermediate frequency furnace 8, and a thin tube 6 is provided at the bottom of the furnace wall; The cover is arranged on the top of the intermediate frequency furnace 8, and the cover is respectively provided with a constant pressure valve 7, a biaxial mechanical stirring device...

Embodiment 2

[0040] A kind of flexible deformable solder, its component content is: the content of Bi is 39wt%, the content of In is 4wt%, the content of Ag is 0.1wt%, the content of Sn is 56.9wt%, and the balance is unavoidable impurity factor ; The purity of Bi ≥ 99.9%, the purity of In ≥ 99.99%, the purity of Ag ≥ 99.99%, and the purity of Sn ≥ 99.999%.

[0041] An automatic preparation device for flexible deformable solder, including an intermediate frequency furnace 8, a cover, a vacuum adjustment system and a control system; the bottom of the intermediate frequency furnace 8 has a taper, and the tail of the intermediate frequency furnace 8 has a taper of 5:1. A flow nozzle 11 is provided at the end, and a solenoid valve 12 connected to the control system is provided on the flow nozzle 11. An inlet pipe 4 and an exhaust pipe 14 are provided on the top of the furnace wall of the intermediate frequency furnace 8, and a thin tube 6 is provided at the bottom of the furnace wall; The cover...

Embodiment 3

[0049] A kind of flexible deformation solder, its component content is: the content of Bi is 45wt%, the content of In is 3wt%, the content of Ag is 0.3wt%, the content of Sn is 51.7wt%; The purity of described Bi is more than or equal to 99.9 %, the purity of In ≥ 99.99%, the purity of Ag ≥ 99.99%, the purity of Sn ≥ 99.999%.

[0050] An automatic preparation device for flexible deformable solder, including an intermediate frequency furnace 8, a cover, a vacuum adjustment system and a control system; the bottom of the intermediate frequency furnace 8 has a taper, and the tail of the intermediate frequency furnace 8 has a taper of 10:1. A flow nozzle 11 is provided at the end, and a solenoid valve 12 connected to the control system is provided on the flow nozzle 11. An inlet pipe 4 and an exhaust pipe 14 are provided on the top of the furnace wall of the intermediate frequency furnace 8, and a thin tube 6 is provided at the bottom of the furnace wall; The cover is arranged on t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap