Net cloth processing method suitable for net-knot-free SE

A processing method, a technology without netting, applied in printing, printing plate preparation, etc., can solve the problems of inaccurate positioning and low work efficiency, and achieve the effect of simple process, accurate graphics and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

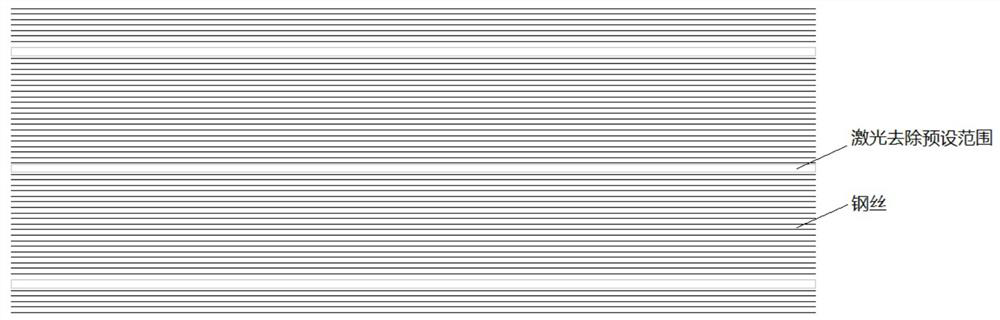

[0027]A mesh processing method suitable for use in non-mesh knuckle SE, including the steps of:

[0028]S1: Place the net plate on the laser device, and use the fixture to secure the net card.

[0029]S2: Set the positioning point on the screen, the machine is connected to the network version by this positioning point;

[0030]S3: Enter a grating parameter in the laser device;

[0031]S4: Remove wire by laser mode;

[0032]Among them, the web version is a non-grid SE-screen version, which includes a grating length, a grating number, and a grating spacing;

[0033]An a mesh processing method suitable for use in non-mesh SE is used for a high-precision mesh processing without net knot SE, and quickly depicts the web pattern of the fine grid setting by the scanning device, and removes the laser device. The steel wire, the scanning process is carried out simultaneously with the laser treatment process, has the advantages of simple process, high yield, no shredded wire, and accurate graphics.

Embodiment 2

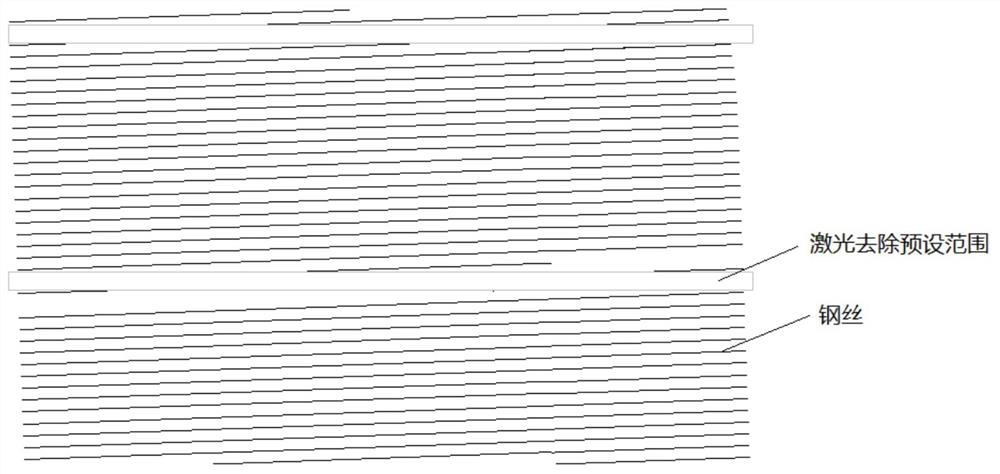

[0035]A mesh processing method suitable for use in non-mesh knuckle SEs, which disclose two wire removal:

[0036]Method 1: The laser device sets the scanning start point according to the positioning point setting of the screen, starting along the wire toward the scanning net plate wire, and the slap is within the preset of the set position, and the wire direction in parallelism ;

[0037]When the wire is removed in this manner, the laser device is removed when the laser is removed, and the wire is removed, and the screen is no residual.

[0038]Method 2: The laser device sets the scan start point according to the positioning point setting of the screen, and the position is scanned from the starting point, and the same direction in the preset range is removed from the absolute value range, and the set range is exceeded. Steel wire reserved.

[0039]In this way, when the wire is removed, a whole steel wire is set within the range of the position of the position, and a part of the cut is cut, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com