Cement clinker hydration suspension concrete early strength agent and application thereof

A cement clinker and concrete technology, which is applied in the field of concrete additives, can solve problems such as insufficient super early strength performance and coagulation accelerator effect, slow cement hydration rate, and crystal nucleus agglomeration, so as to shorten the mold turnover period and promote cement moisture. The effect of chemicalization and early strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

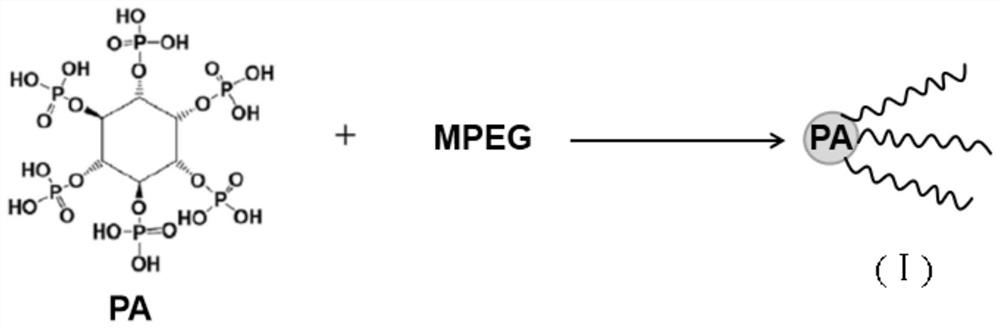

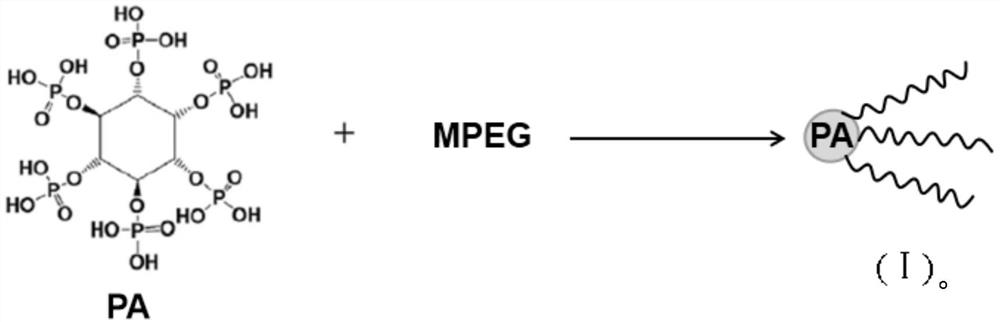

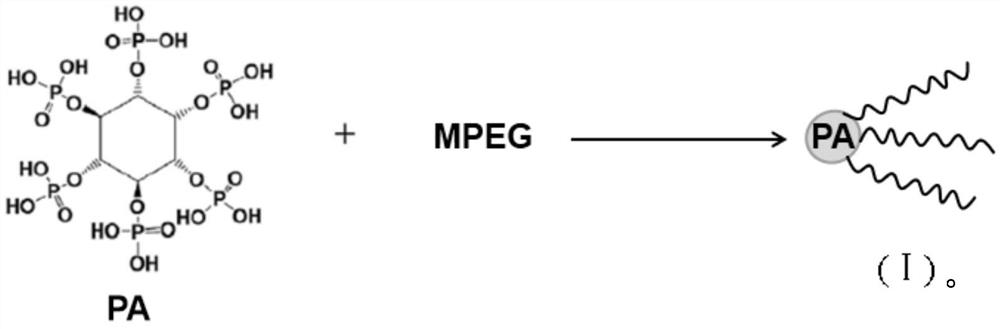

[0026] The preparation method of the phosphonic acid base dispersant of the present embodiment, described method comprises the following steps:

[0027] Add phytic acid and polyethylene glycol monomethyl ether (MPEG2000) at a molar ratio of 1:2 to a four-necked flask equipped with a thermometer, start stirring, and carry out esterification at 115°C for 6 hours under nitrogen blowing to obtain phosphonic acid groups dispersion.

[0028] The preparation method of cement clinker hydration suspension concrete early strength agent of the present embodiment, described method comprises the following steps:

[0029] (1) Add the metered phosphonic acid-based dispersant prepared in this example as a substrate in the reaction bottle, add water to adjust the solid content of the phosphonic acid-based dispersant in the substrate to 25%, and adjust the pH to 9 with alkali;

[0030] (2) Under the condition of 6°C, use the sieve method to slowly add Portland cement clinker with a particle si...

Embodiment 2

[0032] The preparation method of the phosphonic acid base dispersant of the present embodiment, described method comprises the following steps:

[0033] Add phytic acid and polyethylene glycol monomethyl ether (MPEG1000) at a molar ratio of 1:3 to a four-necked flask equipped with a thermometer, start stirring, and carry out esterification at 115°C for 6 hours under nitrogen blowing to obtain phosphonic acid groups dispersion.

[0034] The preparation method of cement clinker hydration suspension concrete early strength agent of the present embodiment, described method comprises the following steps:

[0035] (1) Add the metered phosphonic acid-based dispersant prepared in this example as a substrate in the reaction bottle, add water to adjust the solid content of the phosphonic acid-based dispersant in the substrate to 25%, and adjust the pH to 9 with alkali;

[0036] (2) Under the condition of 6°C, use the sieve method to slowly add Portland cement clinker with a particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com