Method for modifying sawdust

A sawdust and modified technology, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems that the strength and durability of sawdust cement-based composite materials cannot be improved, and the improvement effect is limited, so as to achieve the promotion of strength The effect of development, acceleration of cement hydration, and improvement of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

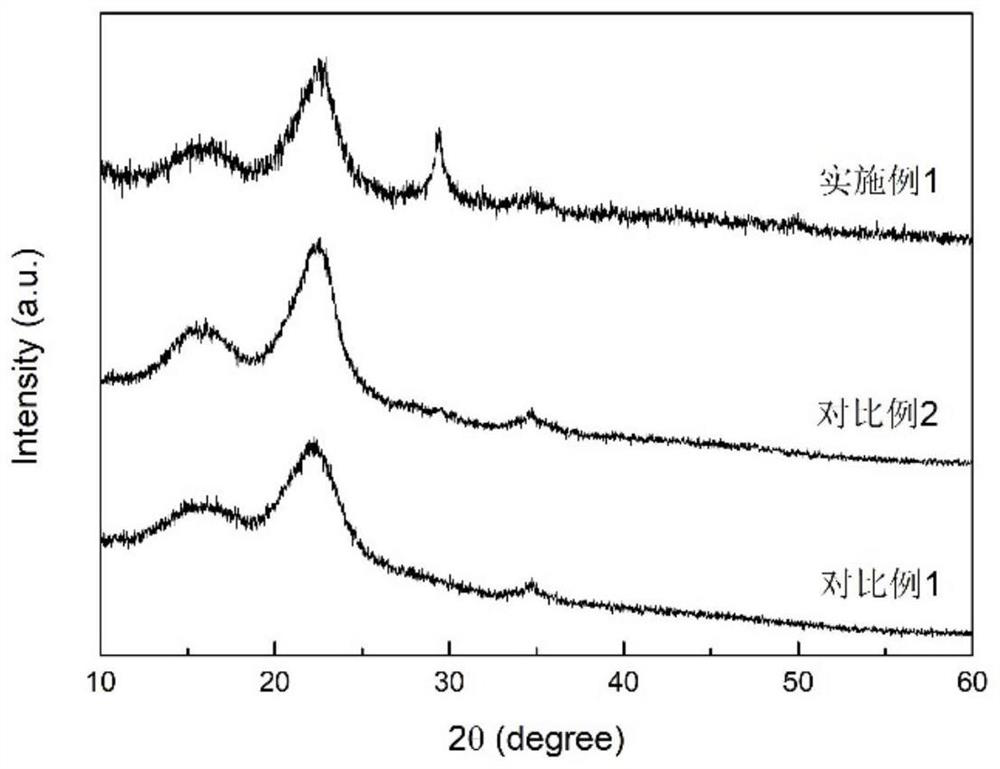

Embodiment 1

[0024] A method for modifying sawdust, comprising the steps of:

[0025] (1) Alkali treatment: Soak 250g of sawdust in 2500g of alkaline silicon source solution for 2 hours to obtain alkali-treated sawdust; wherein, the alkaline silicon source solution is an aqueous solution of sodium metasilicate pentahydrate, and the alkaline silicon source solution contains five The mass concentration of sodium metasilicate in water is 2%, and the temperature of the alkaline silicon source solution is 100°C;

[0026] (2) chemical co-precipitation reaction: while stirring step (1) gained alkali treatment sawdust, add the calcium acetate aqueous solution that molar concentration is 0.5mol / L (calcium ion) wherein, and control the calcium ion in the calcium source and The molar ratio of silicate ions in the alkali solution is 1:1, then continue to stir for 15 minutes, wash again, and vacuum-dry at 60°C to constant weight to obtain calcium silicate hydrate modified sawdust.

Embodiment 2

[0028] A method for modifying sawdust, comprising the steps of:

[0029] (1) Alkali treatment: Soak 250g of sawdust in 1250g of alkaline silicon source solution for 12h to obtain alkali-treated sawdust. The mass concentration of sodium metasilicate in water is 0.5%, and the temperature of the alkaline silicon source solution is 60°C;

[0030] (2) chemical co-precipitation reaction: while stirring step (1) gained alkali-treated sawdust, add the calcium acetate aqueous solution that molar concentration is 0.1mol / L (calcium ion) wherein, and control the calcium ion in the calcium source and The molar ratio of silicate ions in the alkali solution is 2:1, then continue to stir for 15 minutes, wash again, and vacuum-dry at 60°C to constant weight to obtain calcium silicate hydrate modified sawdust.

Embodiment 3

[0032] A method for modifying sawdust, comprising the steps of:

[0033] (1) Alkali treatment: Soak 250g of sawdust in 1800g of alkaline silicon source solution for 6 hours to obtain alkali-treated sawdust. The mass concentration of sodium metasilicate in water is 3%, and the temperature of the alkaline silicon source solution is 40°C;

[0034] (2) chemical co-precipitation reaction: while stirring step (1) gained alkali treatment sawdust, add the calcium acetate aqueous solution that molar concentration is 0.25mol / L (calcium ion) wherein, and control the calcium ion in the calcium source and The molar ratio of silicate ions in the alkali solution is 1.5:1, then continue to stir for 15 minutes, wash again, and vacuum-dry at 60°C to constant weight to obtain calcium silicate hydrate modified sawdust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com