High-strength intergranular-corrosion-resistant twinning induced plastic austenitic stainless steel

A twin-induced plasticity, austenitic stainless steel technology, applied in the field of austenitic stainless steel, can solve the problems of low strength, high cost and use of stainless steel, achieve high corrosion resistance, high strength and corrosion resistance, reduce C The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

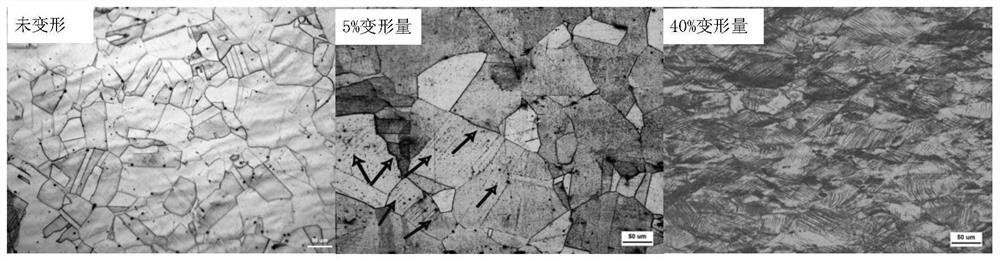

[0028] Example: On the basis of Fe-Mn-12%Cr-C-N steel, reduce the C content to an ultra-low carbon level, increase the Cr content to 16%-20%, increase 2%-4% Ni element, 1%- 3% Si element, control Mn, N element, smelt the Fe-Mn-Cr-Ni-Si-N series TWIP stainless steel of the embodiment of the present invention, the composition is shown in Table 3, and the calculated stacking fault energy is about 49mJ / m 2 .

[0029] Table 3 chemical composition of the stainless steel of the embodiment of the present invention (wt.%)

[0030] C mn Si P S Cr Ni N 0.018 23.98 1.12 0.008 0.005 19.02 3.99 0.60

[0031] Using 50kg vacuum furnace to smelt test steel, forged into The rods are sampled and subjected to solution treatment at 1050°C×40min. use The sample is subjected to a tensile test at a rate of 1mm / min, using a 10×10×55mm sample, and a V-shaped impact test is performed at room temperature. The comparison of mechanical properties between the steel g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com