Steel slag pavement structure and construction method thereof

A pavement structure and steel slag technology, applied in the direction of roads, roads, pavement details, etc., can solve the problem of slow water seepage rate, achieve good water seepage effect, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

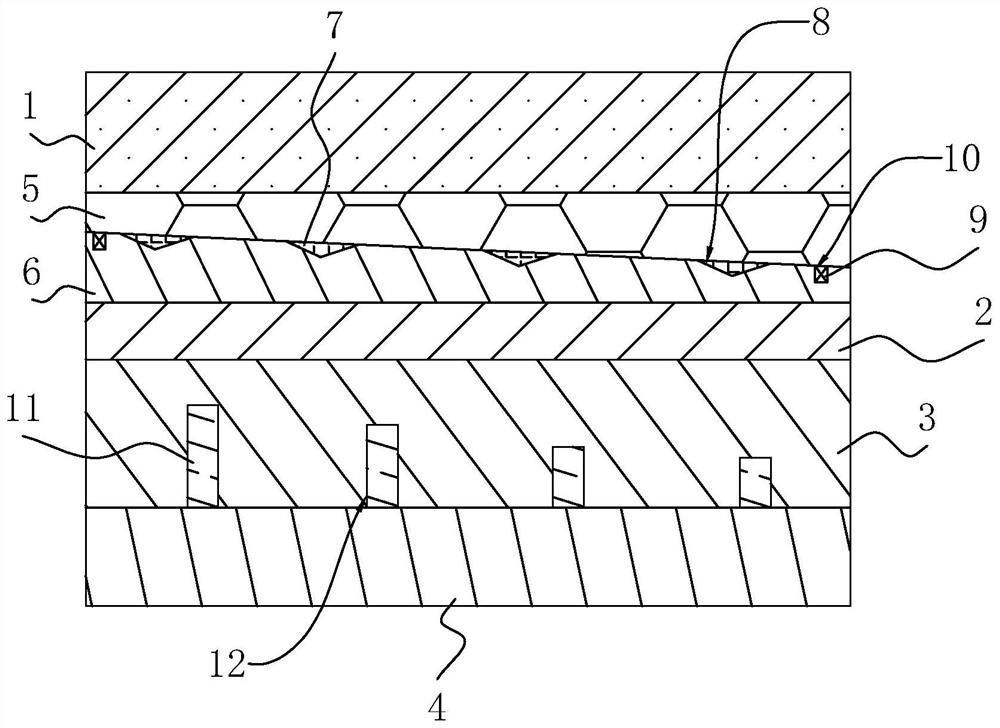

[0043] The embodiment of the present application discloses a steel slag pavement structure. refer to figure 1 , the steel slag pavement structure includes a surface layer 1, a base layer 2, a cushion layer 3 and a siphon connection layer 4 sequentially arranged from top to bottom. , the steel slag with small particle size is conducive to increasing the strength and wear resistance of the surface layer 1, and also ensures the water permeability of the surface layer 1. The base layer 2 and the cushion layer 3 have aggregates with a particle size of 2-30mm mixed with adhesive and cured. The formed moisturizing part is convenient to ensure the water permeability of the base layer 2 and the cushion layer 3. The siphon connection layer 4 is a second solidified part formed by mixing steel slag with a particle size of 2-15mm and plain soil. The steel slag with a large particle size improves the water permeability to ensure the ground Water infiltrates from the surface layer 1, the ba...

Embodiment 2

[0052] The embodiment of the present application discloses a construction method for a steel slag pavement structure, comprising the following steps:

[0053] S1, prepare the material, screen the steel slag, and select the steel slag with a particle size of 2-15mm, the aggregate with a particle size of 2-30mm, and the steel slag with a particle size of 0.1-2mm. Layer 1 hardness, the greater the strength of the steel slag water permeability is better, easy to seepage;

[0054] S2, laying the siphon connection layer 4, first leveling the foundation and cleaning the impurities on the foundation, stirring and mixing steel slag and plain soil with a particle size of 2-15mm, and then laying and compacting;

[0055] S3, laying the cushion layer 3, the aggregate with a particle size of 2-30mm is mixed and solidified by the adhesive and then laid and compacted; after the surface of the cushion layer 3 is laid, four reinforcing blocks 11 are laid on the upper surface of the cushion laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com