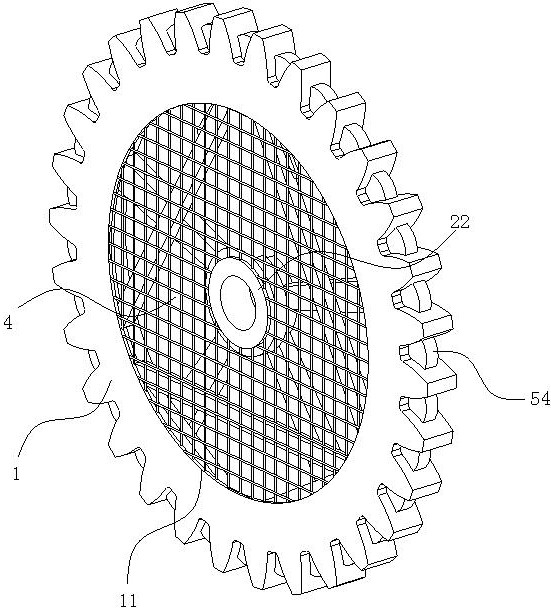

Thin-wall spoke type large gear

A spoke type, large gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of reduced service life of gears, easy deformation, etc., to enhance the bearing capacity, avoid Local deformation, the effect of avoiding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

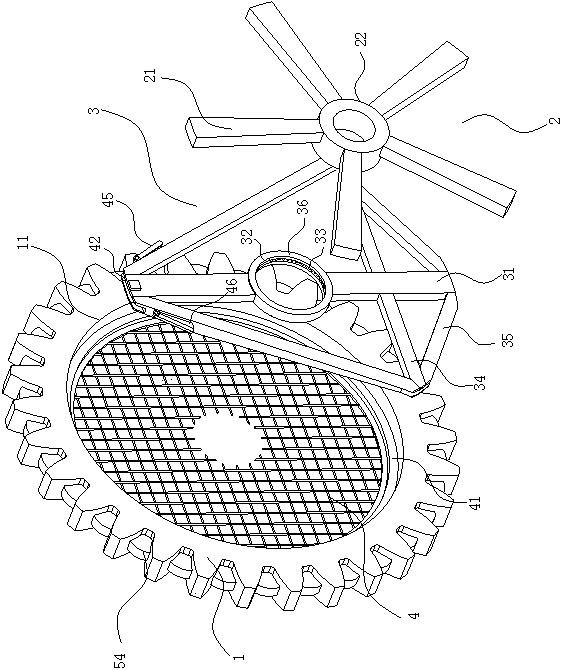

Embodiment approach

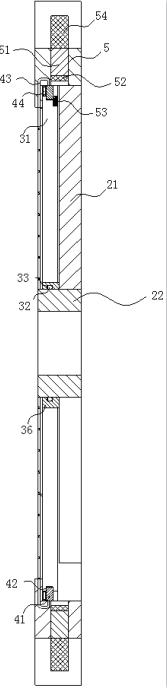

[0033] As an embodiment of the present invention, the first pass groove 11 is secluded from the fixed wheel boke 2 side, and the wire rope 4 is arranged in a mesh shape, when working, when thin wall wheel When the large gear is actuated in a pressure parallel to the main body 1 axis, since the clearance is a gap, it is easy to cause the pressure to act on the wheel brid 3, and the dynamic wheel thread 3 is subjected to pressure to move away from the fixed wheel spokes 2 side, and with the first pass groove 11 "T" shaped junction forms extrusion, under the action of pressure, the first pass groove 11 "T" junction has a trend to berth, the pressure is conducted to the wire rope 4, and the wire rope 4 is connected to the mesh structure. The pressure is dispersed, and the trend of the first passage 11 deformation is performed, preventing a deformation at the first pass groove 11 of the main body 1, resulting in a thin wall spoke large gear unusable.

[0034] As an embodiment of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com