Photovoltaic power station online operation and maintenance method and system based on infrared and visible light images

A photovoltaic power station, infrared image technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems of low accuracy of hot spot detection, high missed detection rate, increase in the frequency of photovoltaic system operating failures, etc. The effect of spot misjudgment rate, accurate positioning, and reduction of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

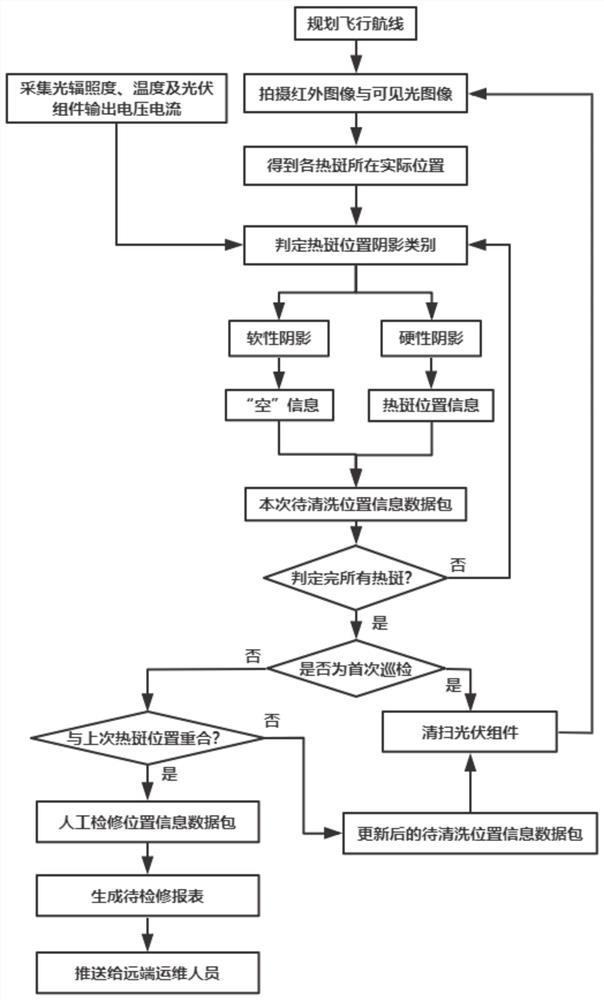

[0052] Such as figure 1 As shown, an online operation and maintenance method of a photovoltaic power station based on infrared and visible light images in this embodiment includes:

[0053] S101: Obtain the infrared image and visible light image, light irradiance, temperature, and output voltage and current of the photovoltaic module of the currently inspected photovoltaic power station.

[0054] In a specific implementation, the infrared image can be collected by an infrared camera, and the visible light image can be collected by a visible light camera; wherein, both the infrared camera and the visible light camera are mounted on the drone.

[0055] The UAV is equipped with a visible light camera to automatically collect orthophoto images of the photovoltaic power station, generate a full orthophoto image of the photovoltaic power station, and formulate the UAV flight route according to the camera performance parameters and the arrangement of the photovoltaic array.

[0056]...

Embodiment 2

[0109] This embodiment provides an online operation and maintenance system for photovoltaic power plants based on infrared and visible light images, which includes:

[0110] The inspection information acquisition module is used to obtain the infrared image and visible light image, light irradiance, temperature and output voltage and current of the photovoltaic module of the photovoltaic power station currently inspected;

[0111] Hot spot position detection module, which is used to stitch and fuse infrared images and visible light images of photovoltaic power plants, extract hot spot features, and obtain the actual position of each hot spot;

[0112] Hot spot position shadow category judgment module, which is used to sequentially determine the shadow category of each hot spot position in combination with light irradiance, temperature and output voltage and current of photovoltaic modules, and then determine whether to send the hot spot position to the position information packe...

Embodiment 3

[0118] This embodiment provides an online operation and maintenance system for photovoltaic power plants based on infrared and visible light images, including:

[0119](1) An information collection device, which is mounted on an unmanned aerial vehicle, is used to collect infrared images and visible light images, light irradiance, temperature, and output voltage and current of photovoltaic modules of the photovoltaic power station currently being inspected.

[0120] For example: UAVs equipped with visible light cameras are used to automatically collect orthophoto images of photovoltaic power plants, generate full orthophoto images of photovoltaic power stations, and formulate UAV flight routes based on camera performance parameters and the arrangement of photovoltaic arrays;

[0121] The drone carries a visible light camera and an infrared camera to take multiple infrared and visible light images of the photovoltaic power station along the photovoltaic panel according to the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com