Chip assembly feeding and discharging machine

A chip and material machine technology, applied in the direction of conveyor objects, transportation and packaging, static electricity, etc., can solve the problems of chip falling off, increasing labor costs, increasing debugging time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments. The descriptions here are used to provide a further understanding of the present invention and constitute a part of the application. The exemplary embodiments of the present invention and their descriptions are used to explain the present invention and do not constitute improper limitations to the present invention.

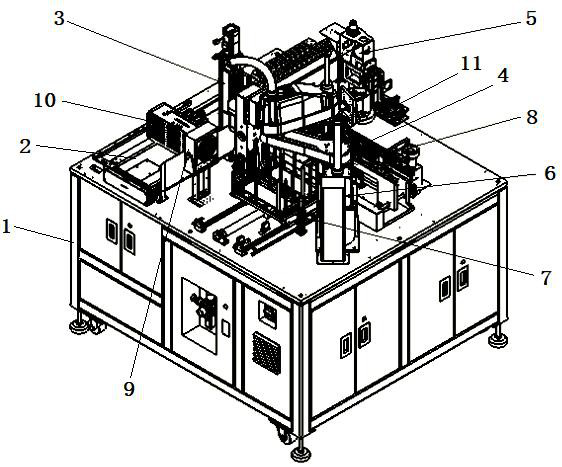

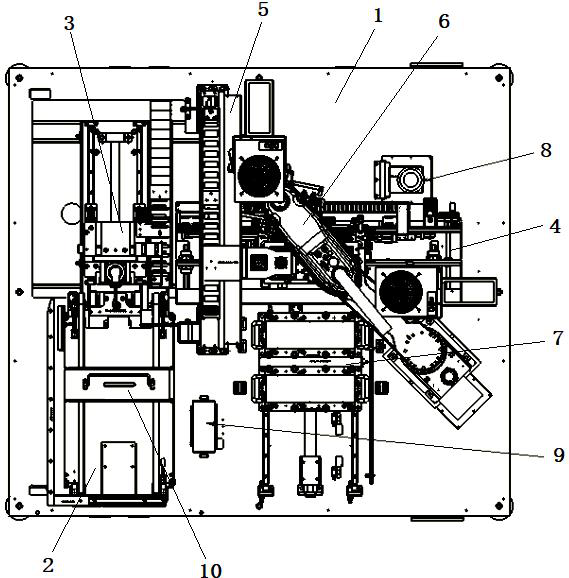

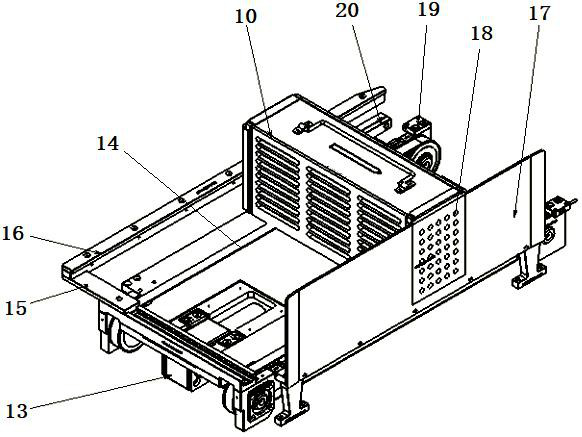

[0057] see Figure 1-2 As shown, a chip assembly loading and unloading machine includes a workbench 1 and a jig bin loading and unloading mechanism 2, a jig bin lifting mechanism 3, a jig wire body 4, Fixture cover disassembly mechanism 5 , chip taking robot 6 , chip loading mechanism 7 , chip shooting camera 8 and ion fan 9 .

[0058] The jig bin loading and unloading mechanism 2 is located at the left front of the workbench 1, and the jig bin elevating mechanism 3 is located at the rear side of the jig bin loading and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com