Atomization device based on Venturi principle and dust falling equipment

An atomization device and Venturi technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve the problems of poor effect in the construction area and high energy consumption, and avoid droplet drift, The effect of reducing waste and improving dust suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

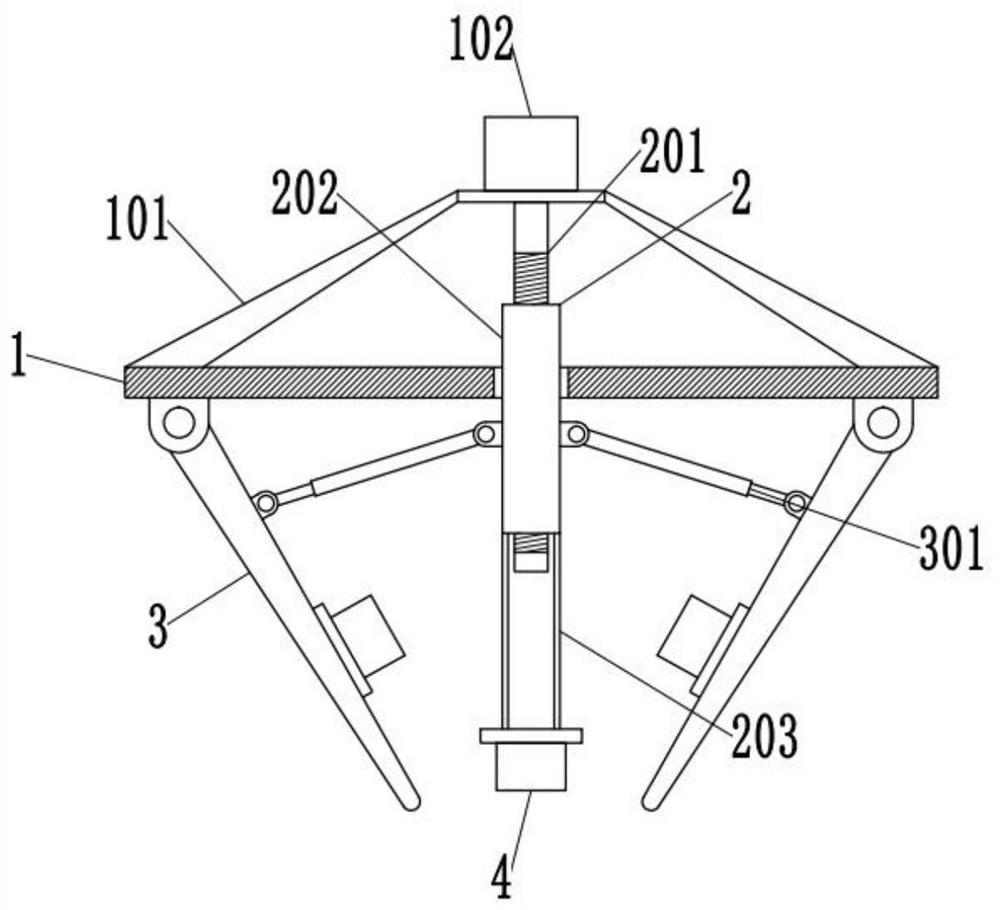

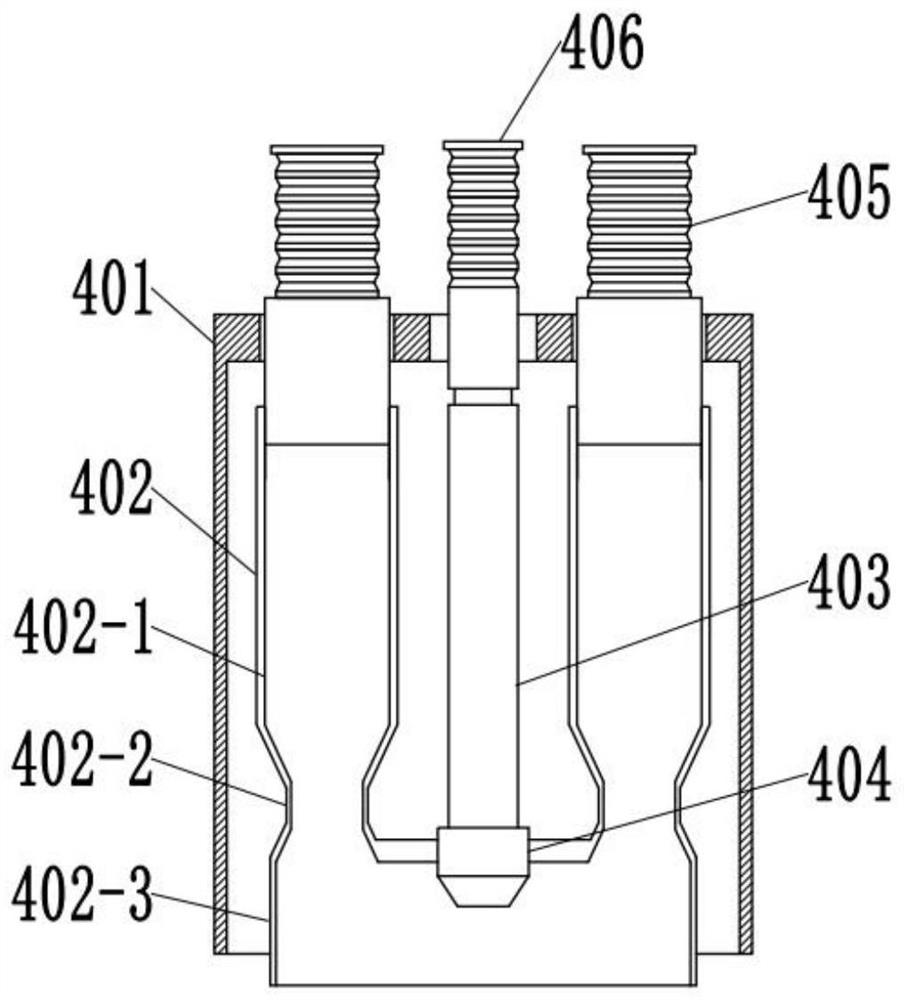

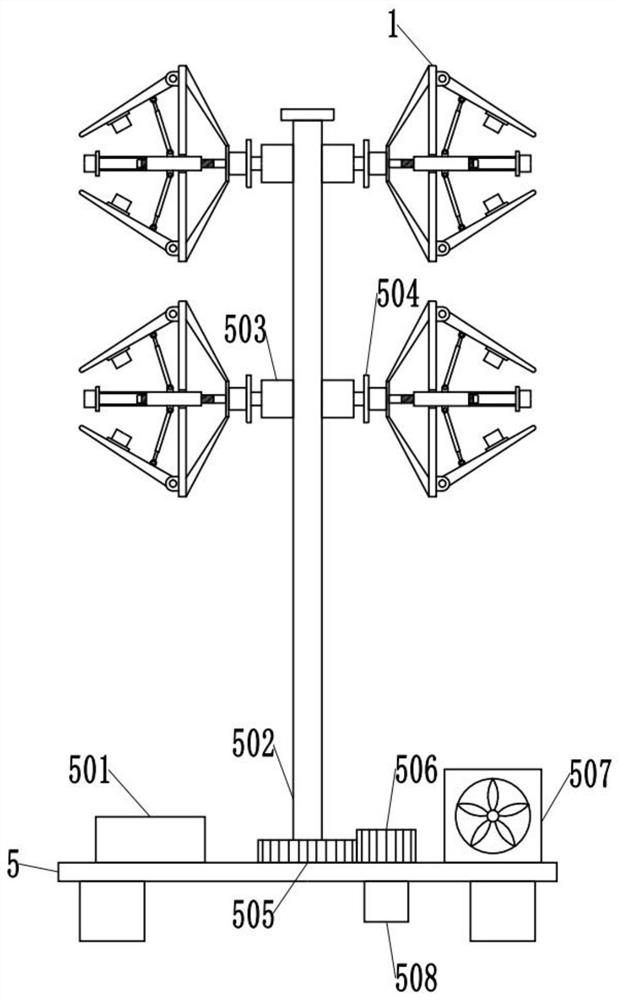

[0029] see Figure 1-2 , in an embodiment of the present invention, an atomizing device based on the Venturi principle includes a mounting plate 1 and an atomizing mechanism 4, the atomizing mechanism 4 includes a casing 401, an air outlet pipe 402 and a water spray pipe 403, and the lower end of the casing 401 Opening, the water spray pipe 403 is fixedly installed in the center position of the casing 401, and the casing 401 is located at the peripheral side of the water spray pipe 403 and is evenly equipped with a number of said air outlet pipes 402; Wide mouth section 402-1, narrow mouth section 402-2 and air outlet section 402-3, wide mouth section 402-1 is wider than air outlet section 402-3 than narrow mouth section 402-2, and each air outlet pipe 402 The air outlet section 402-3 of the air outlet pipe is connected to form a wind shield covering the outside of the water spray pipe 403. When the gas flows along the air outlet pipe 402, it is accelerated under the Venturi e...

Embodiment 2

[0035] see Figure 1-2, in an embodiment of the present invention, an atomizing device based on the Venturi principle includes a mounting plate 1 and an atomizing mechanism 4, the atomizing mechanism 4 includes a casing 401, an air outlet pipe 402 and a water spray pipe 403, and the lower end of the casing 401 Opening, the water spray pipe 403 is fixedly installed in the center position of the casing 401, and the casing 401 is located at the peripheral side of the water spray pipe 403 and is evenly equipped with a number of said air outlet pipes 402; Wide mouth section 402-1, narrow mouth section 402-2 and air outlet section 402-3, wide mouth section 402-1 is wider than air outlet section 402-3 than narrow mouth section 402-2, and each air outlet pipe 402 The air outlet section 402-3 of the air outlet pipe is connected to form a wind shield covering the outside of the water spray pipe 403. When the gas flows along the air outlet pipe 402, it is accelerated under the Venturi ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com