A granulation device for preventing agglomeration of biomass particles

An anti-caking and biomass technology, applied in grain processing and other directions to prevent caking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

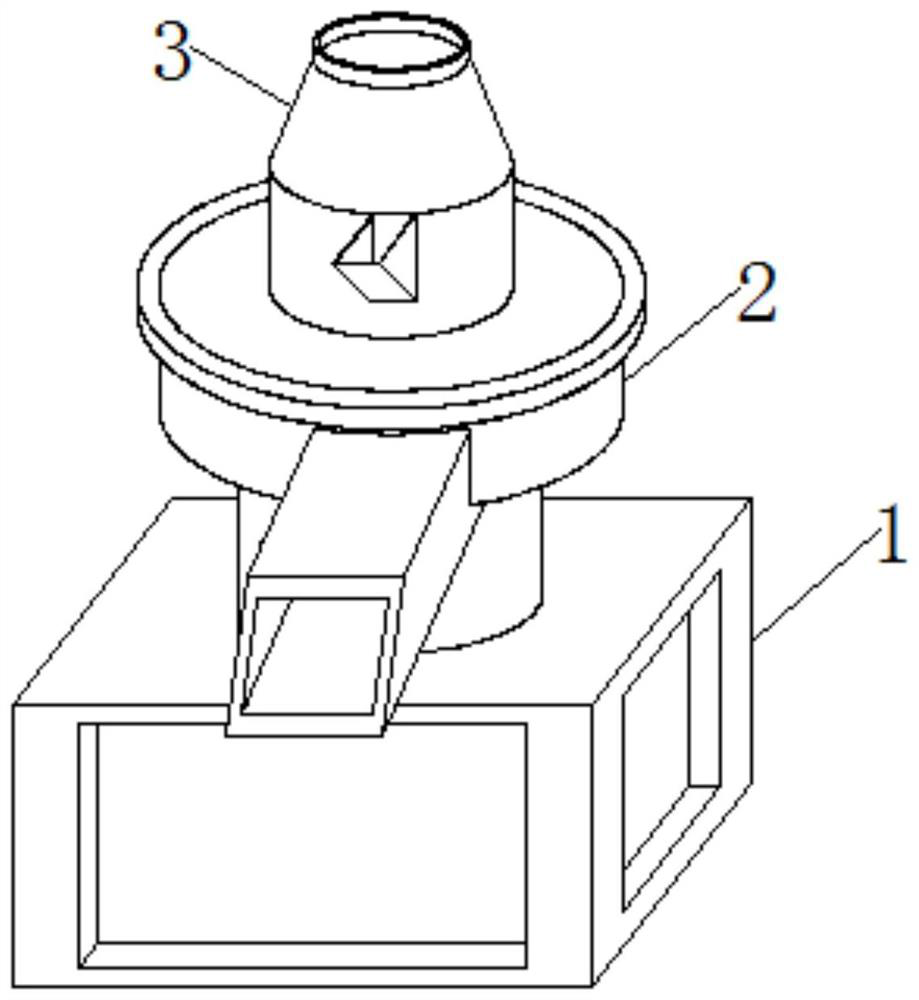

[0035] as attached figure 1 to attach Figure 6 Shown:

[0036] The present invention provides a granulation device for preventing agglomeration of biomass pellets, which includes a main body 1, a granulator 2 and a material inlet 3. The main body 1 puts in granulation raw materials and enters the top of the main body 1 through the material inlet 3 connected above. In the connected granulator 2, the middle part of the granulator 2 is connected to the rotation of the crushing blade 202 to crush, cut and granulate the raw materials;

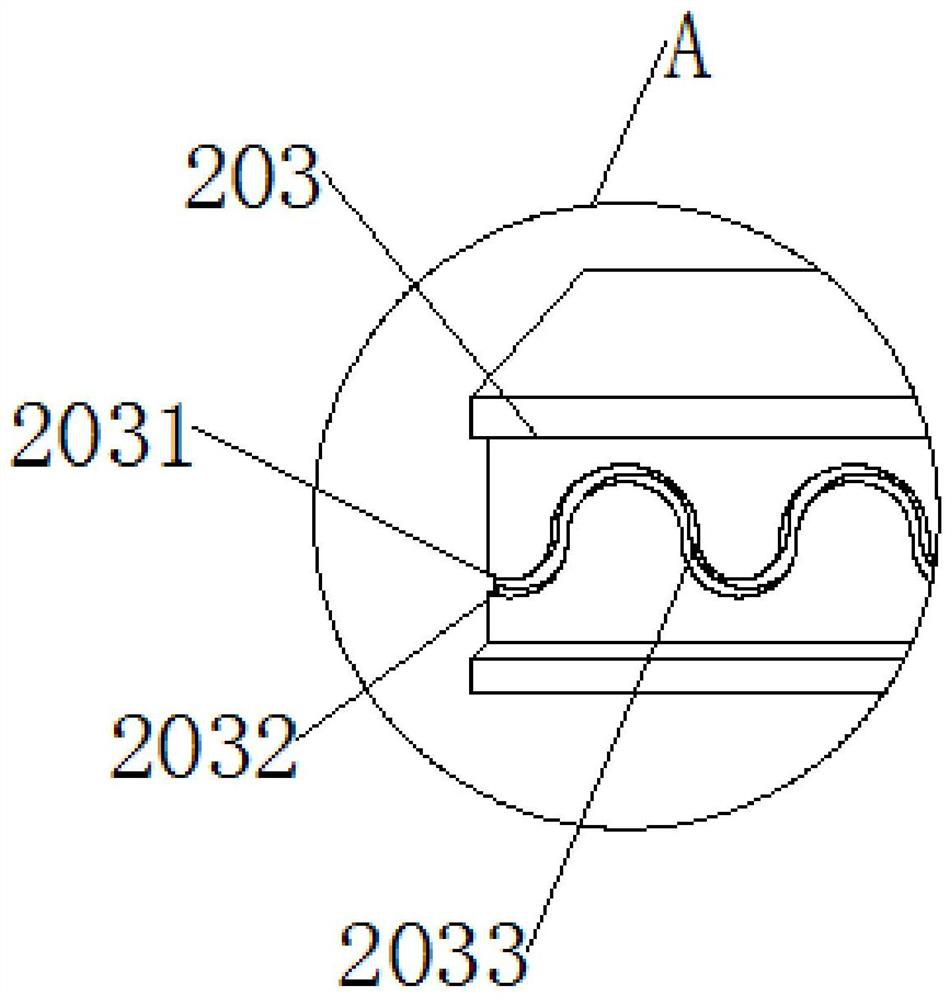

[0037] The deflection groove 2033, the deflection groove 2033 is grooved for the fitting groove 2031 and is a groove with a curved arc.

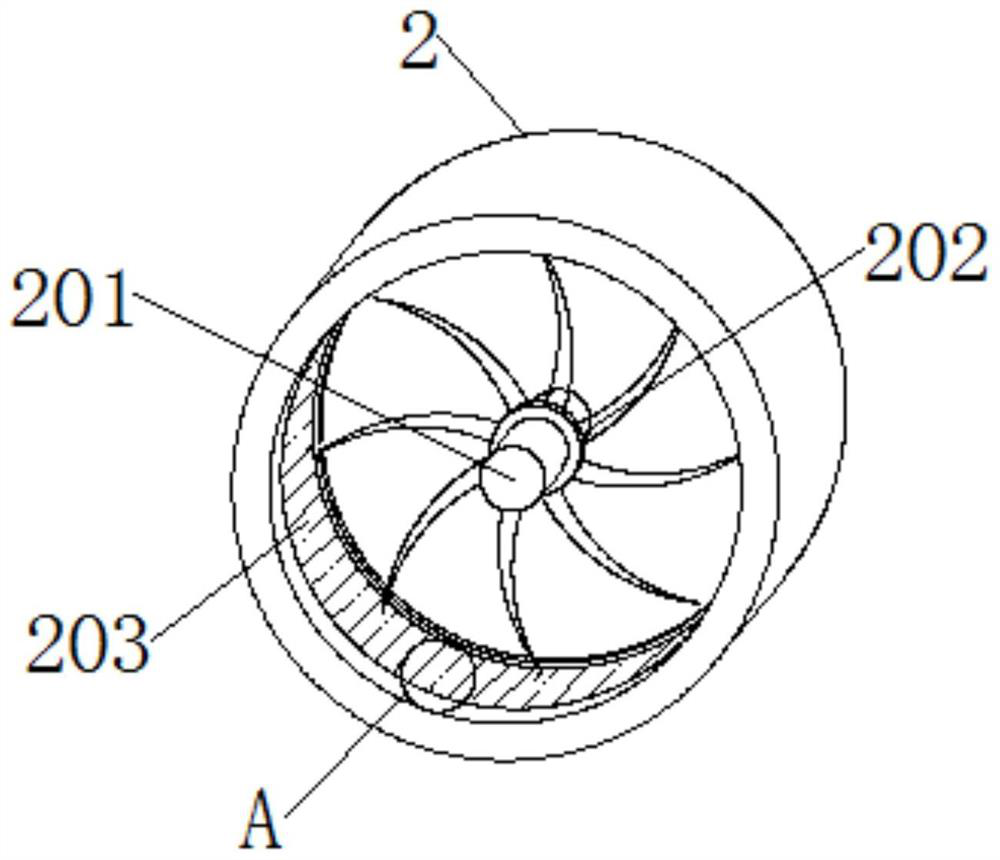

[0038] Wherein, the granulator 2 includes;

[0039] Rotating shaft 201, the rotating shaft 201 is a circular shaft that runs through the middle of the granulator 2 and is electrically connected to the motor inside the main body 1;

[0040] The crushing blade 202, the crushing blade 202 is an arc curved blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com