Production device and method for graphene heat transfer enhanced multilayer composite pipe

A multi-layer composite and production device technology, which is applied to spray devices, devices that apply liquid to surfaces, coatings, etc. The effect of enhanced corrosion ability, high production efficiency and elimination of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

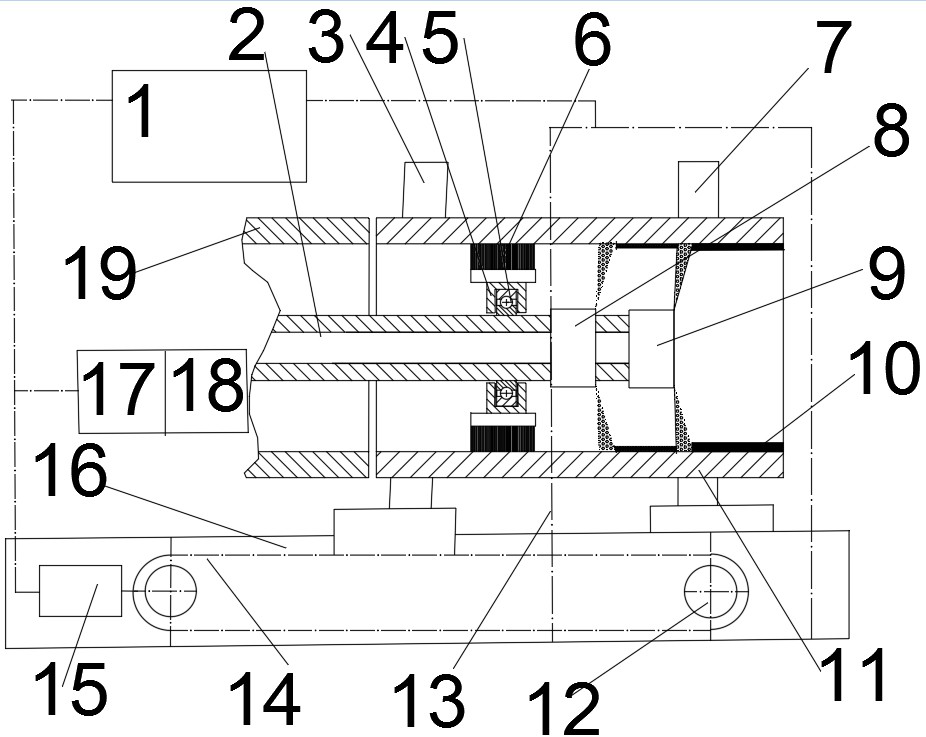

[0041] figure 1 It is a schematic diagram of the device of the present invention, in the figure (1) is the operation and control system, the control system adopts PLC mode, embedded with wifi; (2) is a hard tube, and the whole section of the resin delivery tube and the composite resin delivery tube are covered with a metal tube (3) It is a metal tube rotating device, which is a combined mechanism, including a rotating motor, a bearing, a shaft, a metal tube clamping device, and a support. The rotating motor is fixed on the support, and the shaft is fixed on the support through the bearing. The tube clamping device is connected to the shaft through a mechanical connection. The rotating motor drives the shaft to rotate through the transmission mechanism. The metal tube clamping device adopts a rigid three-jaw chuck structure; There is a gap of not less than 1mm between the outer diameters of the hard tubes; (5) is the hard tube support bearing, which uses a radial bearing; (6) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com