Device and method for preparing stainless steel/aluminum/stainless steel layered composite plate

A technology of stainless steel layer and stainless steel plate, applied in metal processing equipment, metal rolling, manufacturing tools, etc., to achieve the effects of reducing rolling resistance, increasing interface bonding strength, and weakening deformation differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

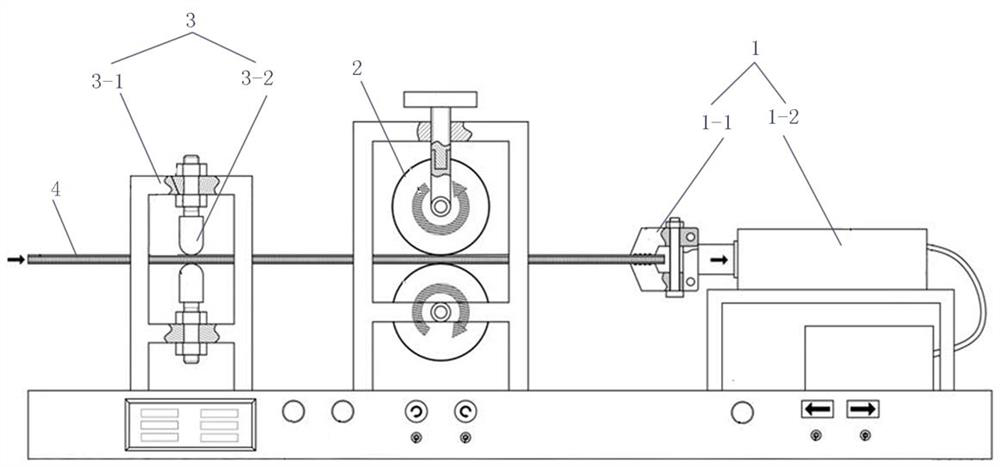

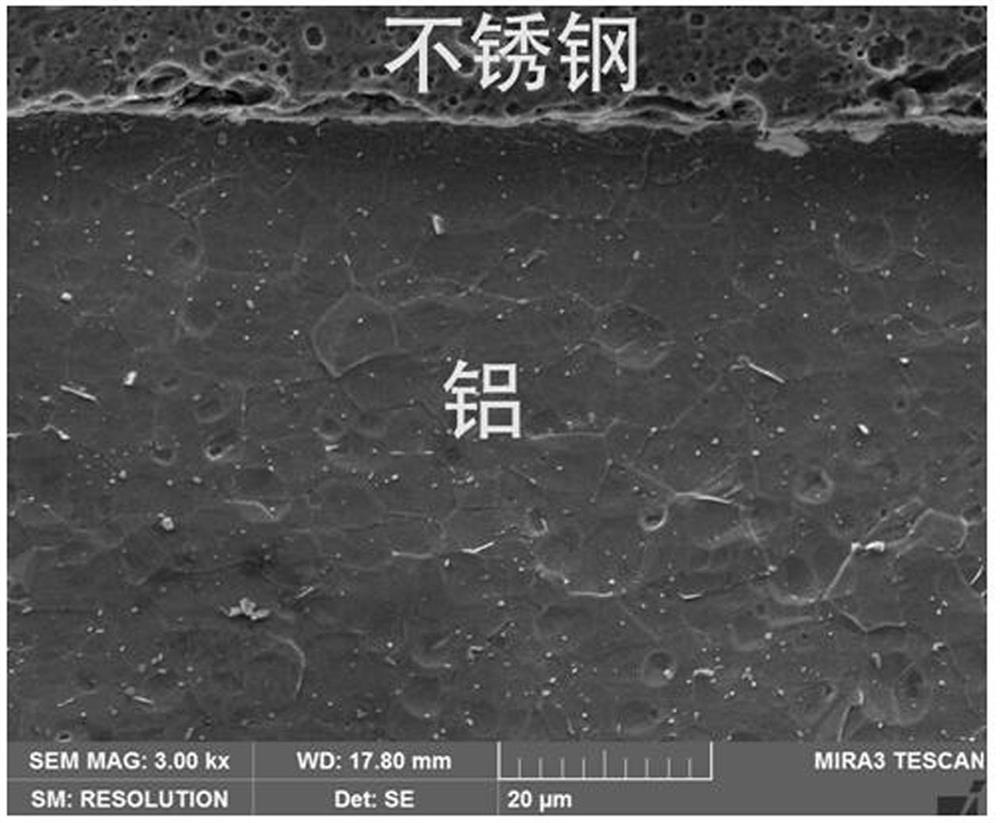

[0033] Example 1: Polish the surface of 0.1 mm thick stainless steel plate and 0.5 mm thick aluminum plate to smooth, and clean the oil stain; the pretreated stainless steel plate and aluminum plate are stacked in the order of stainless steel plate / aluminum plate / stainless steel plate to form a laminated plate 4 , laminated plate 4 superimposed thickness t 0 =0.7mm; first pass the laminated plate 4 through the clamping device 3 and the rolling mill 2 in turn, and then use the clamp body 1-1 to clamp and fix the tail of the laminated plate 4; adjust the working distance of the clamping device 3 to 0.65 mm, adjust the roll spacing of rolling mill 2 to 0.64 mm, set the roll line speed of rolling mill 2 to 5m / min, and set the moving speed of clamp body 1-1 to 5.25m / min. Such as figure 2 The microstructure of the cross-section of the stainless steel / aluminum / stainless steel laminated composite plate is shown, and it can be concluded that the interfacial bonding of the stainless s...

Embodiment 2

[0034] Example 2: Polish the surface of 0.3mm thick stainless steel plate and 1.0mm thick aluminum plate to smooth, clean up the oil stain; the pretreated stainless steel plate and aluminum plate are stacked in the order of stainless steel plate / aluminum plate / stainless steel plate to form a laminated plate 4. Laminated board 4 superimposed thickness t 0 =1.6mm; first pass the laminated plate 4 through the clamping device 3 and the rolling mill 2 in turn, and then use the clamp body 1-1 to clamp and fix the tail of the laminated plate 4; adjust the working distance of the clamping device 3 to 1.5 mm, adjust the roll spacing of rolling mill 2 to 1.5 mm, set the roll line speed of rolling mill 2 to 3m / min, and set the moving speed of clamp body 1-1 to 3.3m / min.

Embodiment 3

[0035]Example 3: The surfaces of the 0.5 mm thick stainless steel plate and the 4.0 mm thick aluminum plate are polished smooth, and the oil stains are cleaned; the pretreated stainless steel plate and aluminum plate are stacked in the order of stainless steel plate / aluminum plate / stainless steel plate to form a laminated plate 4 , laminated plate 4 superimposed thickness t 0 =5mm; first pass the laminated plate 4 through the clamping device 3 and the rolling mill 2 in sequence, and then use the clamp body 1-1 to clamp and fix the tail of the laminated plate 4; adjust the working distance of the clamping device 3 to 4.5 mm , adjust the roll spacing of rolling mill 2 to 4..5mm, set the roll line speed of rolling mill 2 to 2m / min, and set the moving speed of clamp body 1-1 to 3m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com