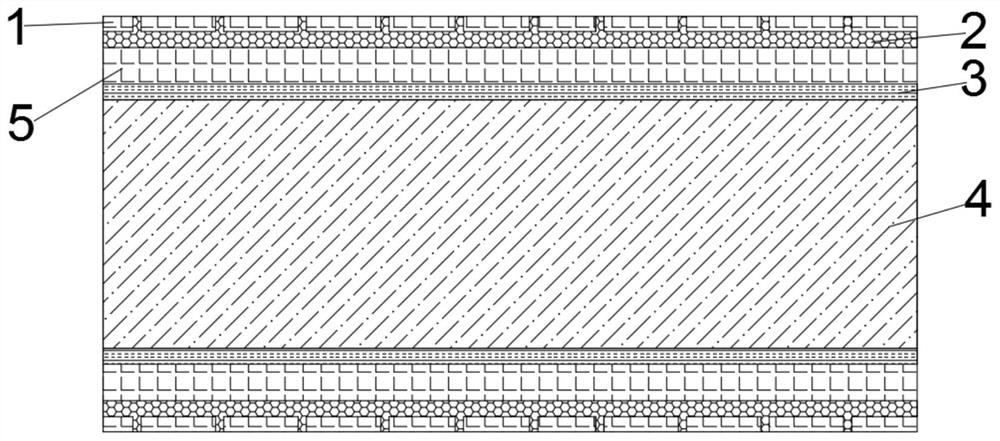

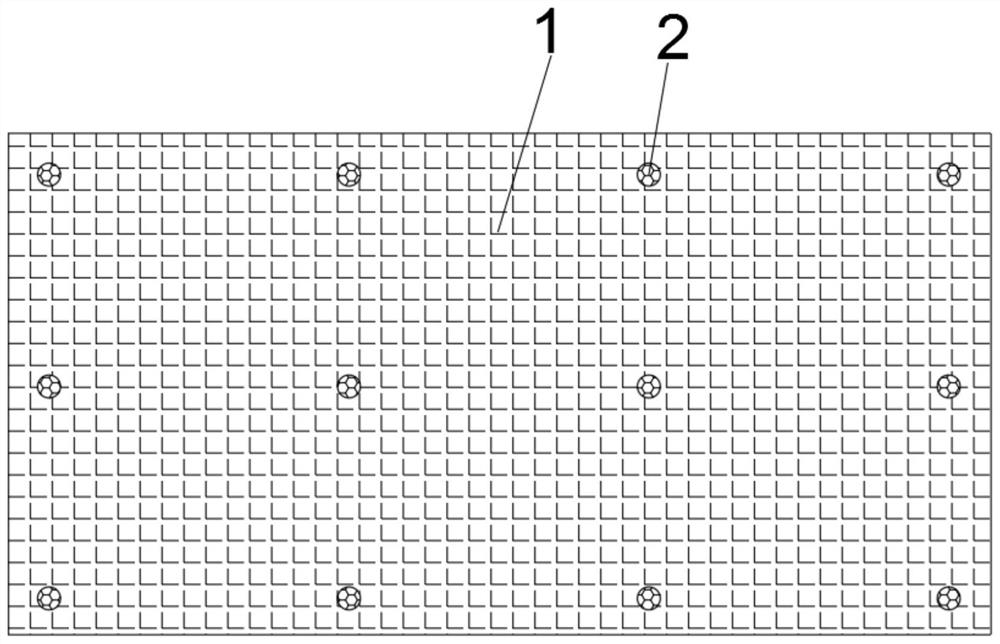

Fireproof flame-retardant aluminum-plastic composite plate and preparation method thereof

An aluminum-plastic composite panel, fire-retardant and flame-retardant technology, applied in the chemical industry, can solve the problems of human body damage, short service life, easy oxidation of fire-resistant and flame-retardant aluminum-plastic composite panels, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] One embodiment of the preparation method of a fire-resistant and flame-retardant aluminum-plastic composite board of the present invention, the raw materials are calculated in parts by mass, and the preparation method includes the following steps: add 20 parts of polyethylene and 10 parts of polypropylene to the reaction kettle, and adjust the temperature to Stir at 140°C for 30 minutes to melt the polyethylene and polypropylene for later use, add the treated polyethylene and polypropylene into the activated ribbon mixer, and then add 10 parts of tricumyl phosphate, 5 parts of zinc molybdate and 8 parts of antimony trioxide, a flame retardant synergist, are guaranteed to be added for 20 minutes, and the materials initially mixed by the ribbon mixer are added to the internal mixer, and treated for 30 minutes at a temperature of 100°C. After the refining is completed, use an extruder to extrude hot-cut pellets, use an open mill to plasticize into sheets, and use a flat pel...

Embodiment 2

[0040] One embodiment of the preparation method of a fire-resistant and flame-retardant aluminum-plastic composite board of the present invention, the raw materials are calculated in parts by mass, and the preparation method comprises the following steps: adding 22 parts of polyethylene and 8 parts of polypropylene to the reaction kettle, and adjusting the temperature to Stir at 140°C for 35 minutes to melt the polyethylene and polypropylene for later use. Add the treated polyethylene and polypropylene into the activated ribbon mixer, and then add 10 parts of tricumyl phosphate, 5 parts of calcium molybdate and 8 parts of antimony trioxide, a flame retardant synergist, are guaranteed to be added for 30 minutes, and the materials initially mixed by the ribbon mixer are added to the internal mixer for 35 minutes, and the treatment temperature is 100 ° C. After the refining is completed, use an extruder to extrude hot-cut pellets, use an open mill to plasticize into sheets, and us...

Embodiment 3

[0047] An embodiment of the preparation method of a fire-resistant and flame-retardant aluminum-plastic composite board of the present invention, the raw materials are calculated in parts by mass, and the preparation method comprises the following steps: adding 25 parts of polyethylene and 5 parts of polypropylene to the reaction kettle, and adjusting the temperature to Stir at 140°C for 40 minutes to melt the polyethylene and polypropylene for later use. Add the treated polyethylene and polypropylene into the activated ribbon mixer, and then add 10 parts of triphenyl phosphate, molybdic acid 5 parts of calcium and 8 parts of antimony trioxide, a flame retardant synergist, the time of addition is guaranteed to be 30 minutes, and the materials initially mixed by the ribbon mixer are added to the internal mixer, and the processing temperature is 100 ℃ for 40 minutes, and the internal mixing is completed Finally, use an extruder to extrude hot-cut granules, use an open mill to mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com