Construction method of water-damage-resistant reinforced protection structure of existing bridge bearing platform

A technology for protective structures and construction methods, applied in bridge reinforcement, infrastructure engineering, bridges, etc., can solve the problems of inappropriate anti-scour requirements, low pile caps, high working environment requirements, and high cost of carbon fiber cloth, so as to improve concrete performance. Pouring quality, increased durability, accurate cutting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

[0035] The construction method for the anti-water damage reinforcement and protection structure of the bridge cap in active service includes the following construction steps:

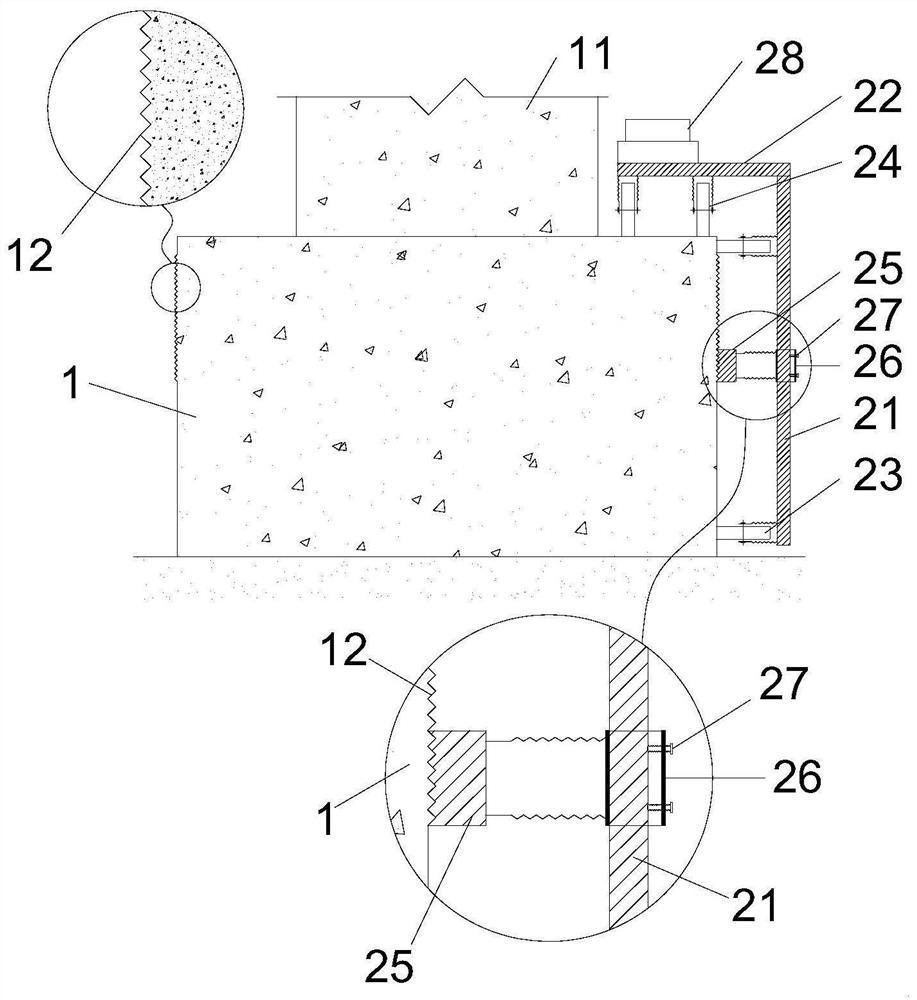

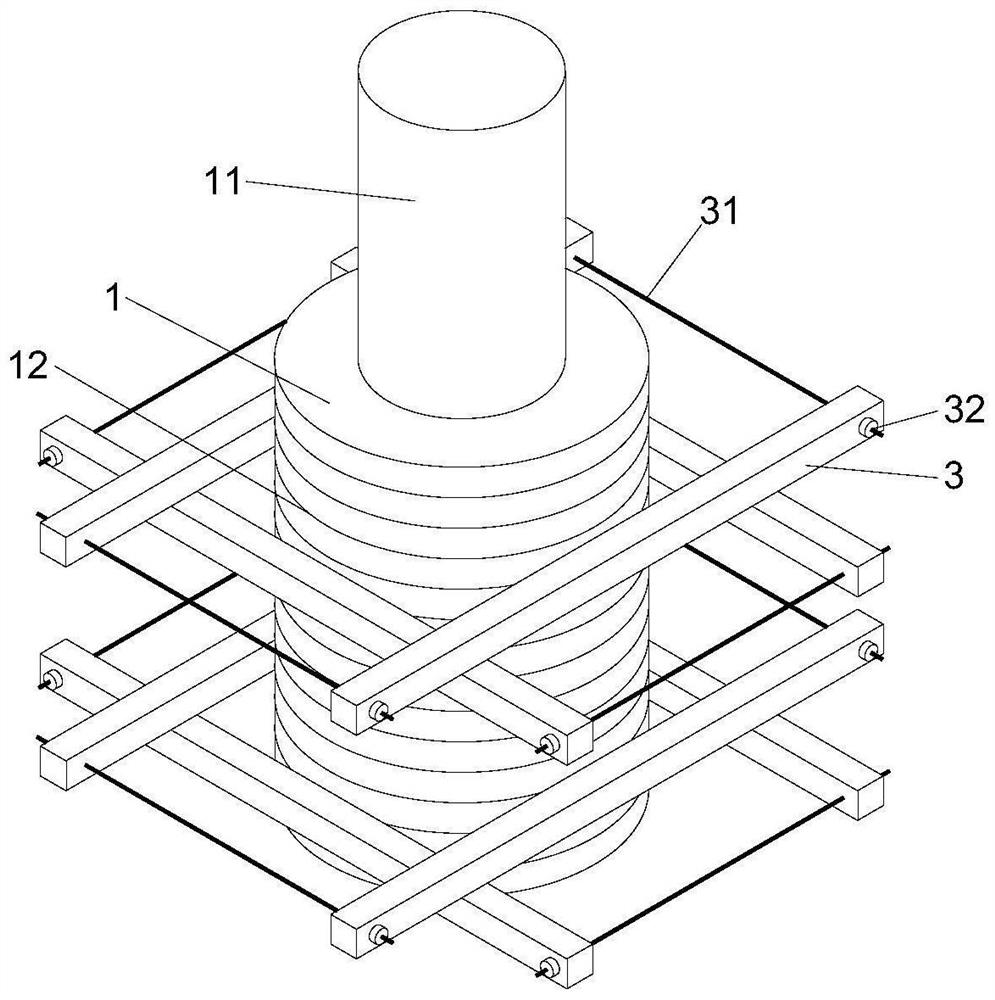

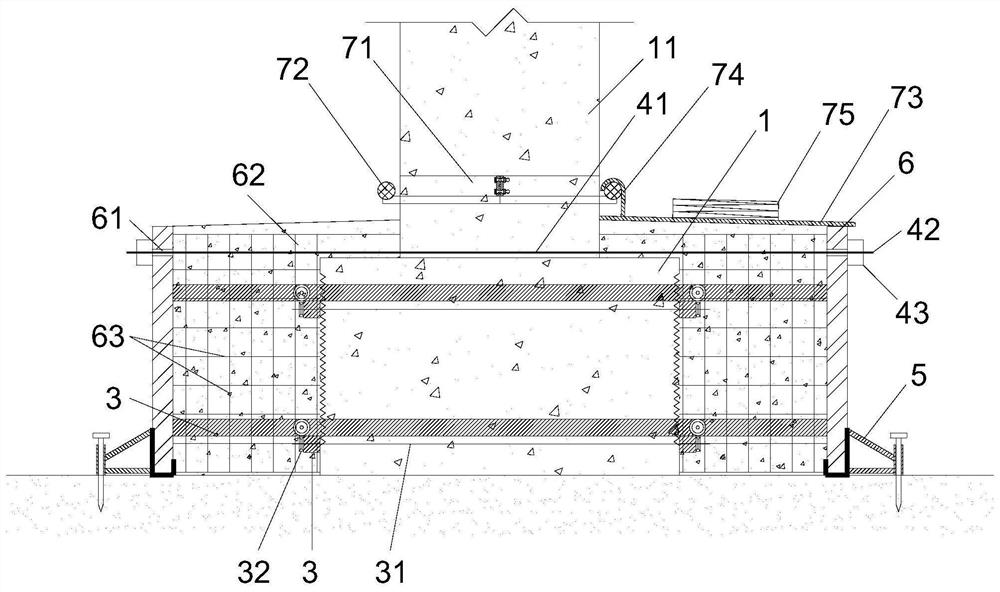

[0036] 1) Construction of the chiseling structure 12 on the side of the cap 1 in active service is carried out using a guided chisel cutting device to form a layer of chiseling structure 12 on the side of the cap 1 in active service; as attached figure 1 As shown, the guided chisel cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com