Hall thruster heat conduction support and Hall thruster comprising same

A technology of Hall thruster and heat-conducting support, which is applied in thrust reverser, machine/engine, plasma utilization, etc., can solve the problems of poor thermal stability of Hall thruster with high specific impulse and high power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

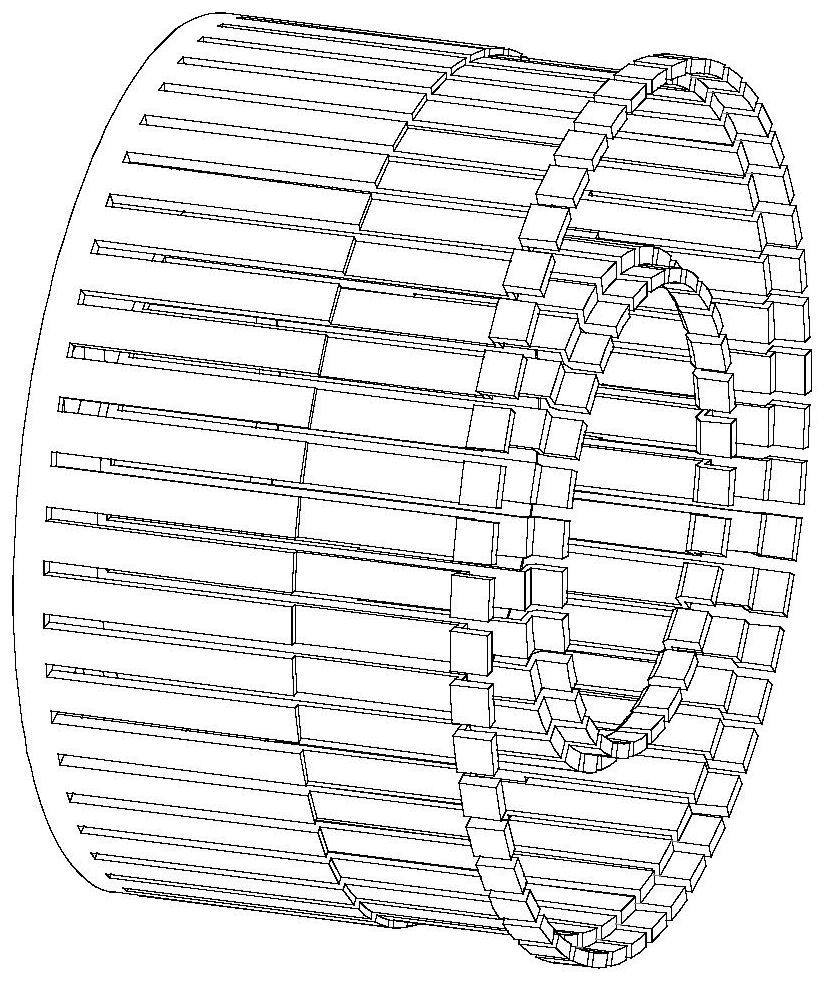

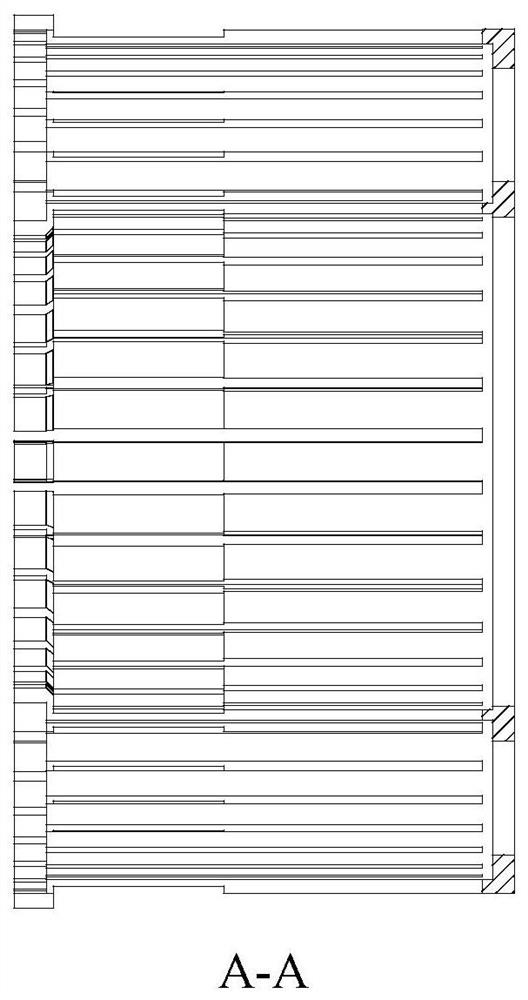

[0014] Specific implementation mode one: refer to Figure 1 to Figure 3 This embodiment is described in detail. The Hall thruster heat conduction support described in this embodiment includes two cylinders with the same length and coaxially nested inside and outside. The length of the two cylinders is both 70 mm. The same ends of the two cylinders are connected through a bottom plate, the bottom plate is ring-shaped, and a plurality of through holes uniformly arranged along its circumferential direction are arranged on the bottom plate.

[0015] Specifically, the outer diameter of the inner cylinder is the same as the inner diameter of the bottom plate, one end of the cylinder is connected to the inner ring of the bottom plate, the inner diameter of the outer cylinder is the same as the outer diameter of the bottom plate, and one end of the cylinder is connected to the outer ring of the bottom plate.

[0016] Considering that the high-energy particles of the Hall thruster main...

specific Embodiment approach 2

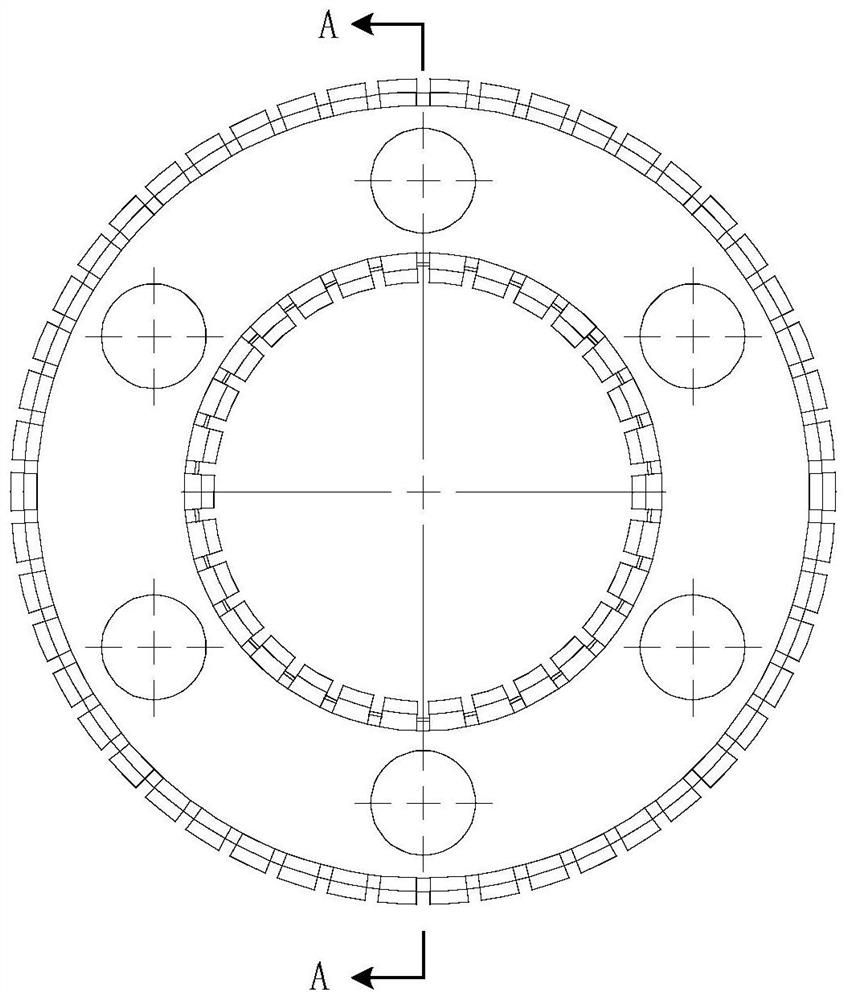

[0022] Specific implementation mode two: refer to Figure 4 and Figure 5 Describe this embodiment in detail. This embodiment is a Hall thruster including the heat conduction bracket of the Hall thruster described in Embodiment 1. The heat conduction bracket 7 of the Hall thruster is covered outside the discharge channel 6 of the Hall thruster. The distance between the inner cylinder and the inner magnetic shield 4 of the Hall thruster heat conduction bracket 7 is 1.5 mm, and the surface of the inner magnetic shield 4 opposite to the inner cylinder is electroplated to reduce the surface radiation Coefficient, to reduce the heat radiation power of the Hall thruster heat conduction bracket to the inner magnetic shield 4.

[0023] An aluminum Hall thruster heat conduction bracket 7 is added outside the ceramic discharge channel 6 of the traditional Hall thruster to guide the heat flow generated on the discharge channel 6, and guide the heat flow on the inner ceramic to the exter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com