Novel automatic oil supplementing equipment

An automatic oil replenishment, a new type of technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve the problems of inaccurate oil control, difficulty in ensuring safety, and high oil injection costs, reducing oil consumption and saving maintenance. Cost, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

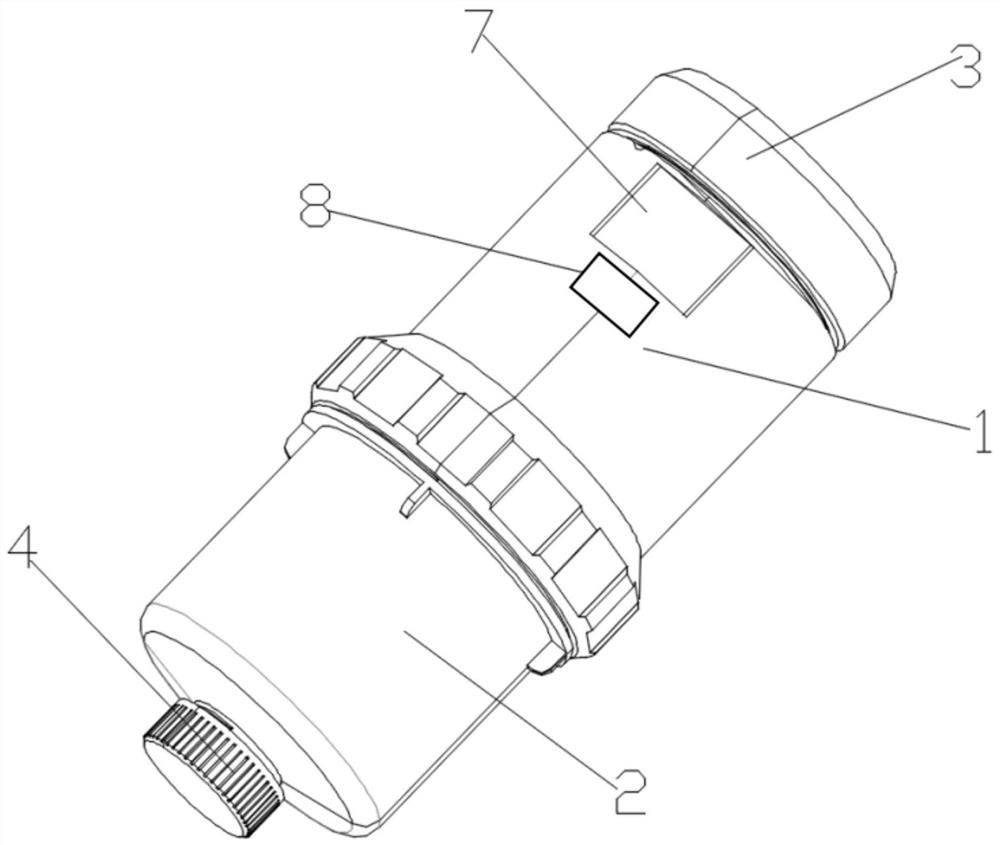

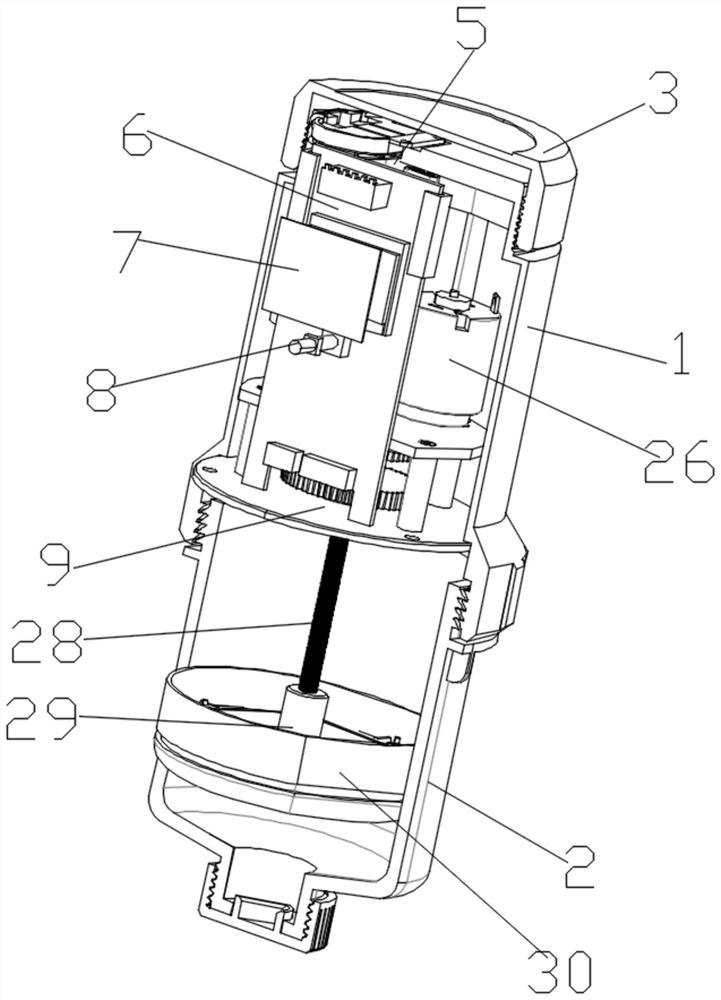

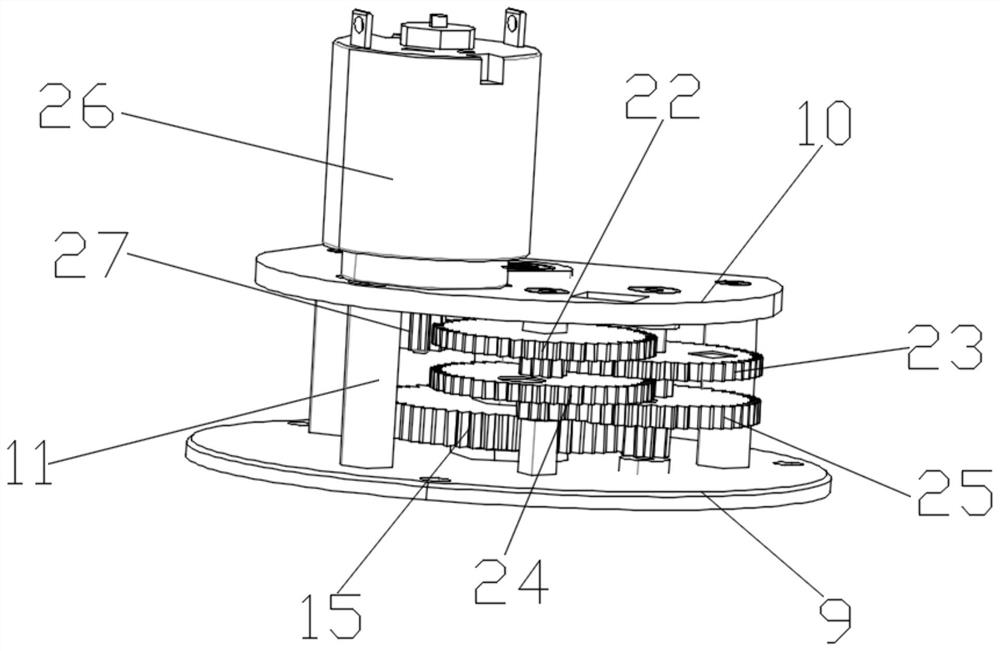

[0034] Such as Figure 1-9As shown, the embodiment of the present invention provides a new type of automatic oil replenishment equipment, which includes a top control box 1 and a bottom oil box 2. Because the vibrating oil cup will not fall off due to the screw thread during the operation of large-scale equipment, a battery box 5 and a circuit board 6 are arranged at the upper end of the top control box 1, and a USB interface is provided on the circuit board 6, through the USB interface. The program is edited, and the entire device can be controlled through the circuit board 6 to realize intelligent oil filling, and the circuit board 6 is also equipped with a Bluetooth connection function, and the status display can be viewed through the Bluetooth connection. Turn off the parameters such as oil frequency and oil replenishment setting first. A display screen 7 is fixedly embedded on one side wall of the top control box 1. The display screen 7 has low power consumption LED backl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap