Gradient utilization device for diffused gas self-sustaining catalytic combustion sensible heat

A technology for releasing gas and catalytic combustion, applied in the combustion method, combustion type, combined combustion mitigation, etc., can solve problems such as energy waste, lack of feedback from control systems, and inability to meet the needs of self-sustaining catalytic gas temperature, to reduce emissions, The effect of improving the scope of applicability and work efficiency, and improving the utilization efficiency of waste heat resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

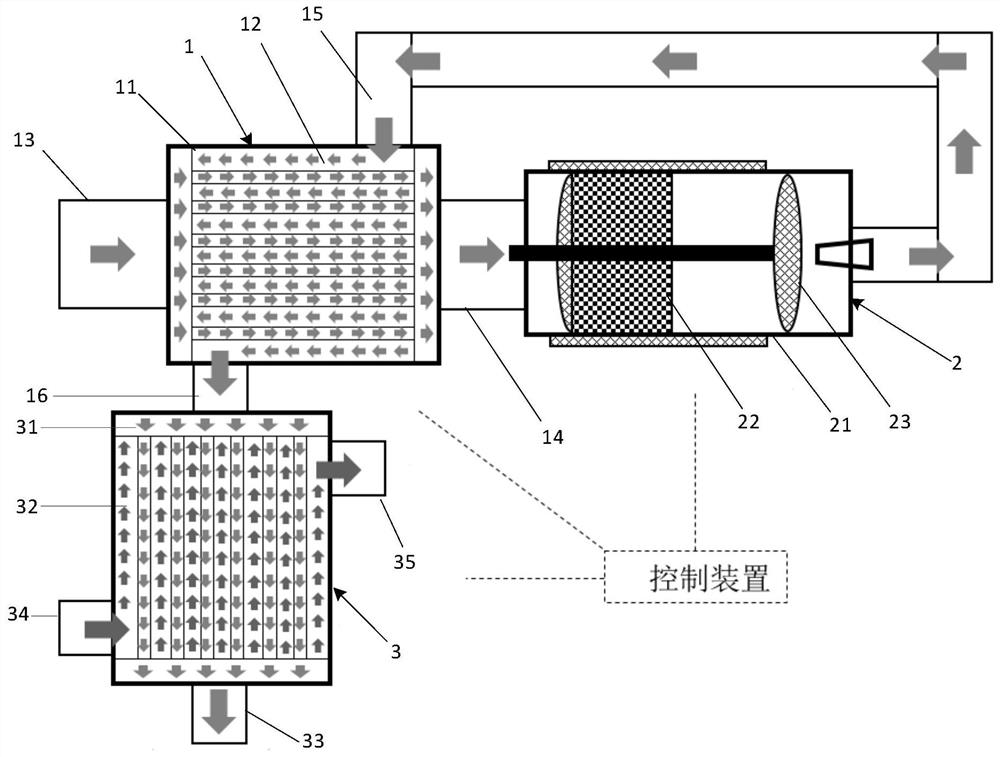

[0016] Such as figure 1 As shown, in one embodiment of the present invention, a self-sustaining catalytic combustion sensible heat cascade utilization device for vented gas is disclosed, including a preheating device 1 , a catalytic combustion device 2 , a sensible heat recovery device 3 and a control system 4 .

[0017] The preheating device 1 includes a preheating chamber 11 with a preheating pipeline 12 inside, a gas inlet 13 connected to the flue is connected to the preheating chamber 11, and a gas outlet 14 that releases the gas after outputting preheating, and is connected with the preheating chamber 11. The high temperature inlet 15 and the high temperature outlet 16 are respectively connected at both ends of the preheating pipeline 12; the flue is used as a smoke exhaust channel for converter steelmaking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com