Building and closed space high-temperature sterilization and new coronavirus elimination heat pump air conditioning device and application thereof

A closed space, heat pump air conditioning technology, applied in space heating and ventilation, space heating and ventilation control input, application, etc., can solve the problem that ozone is easy to enter heat pump air conditioning device, difficult to configure air sterilization and disinfection system, difficult to dynamic sterilization and disinfection. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]This embodiment provides a heat pump air conditioner for high-temperature sterilization and sterilization of novel coronavirus in buildings and enclosed spaces. Here, the building or the enclosed space has an air-conditioned space S within it.

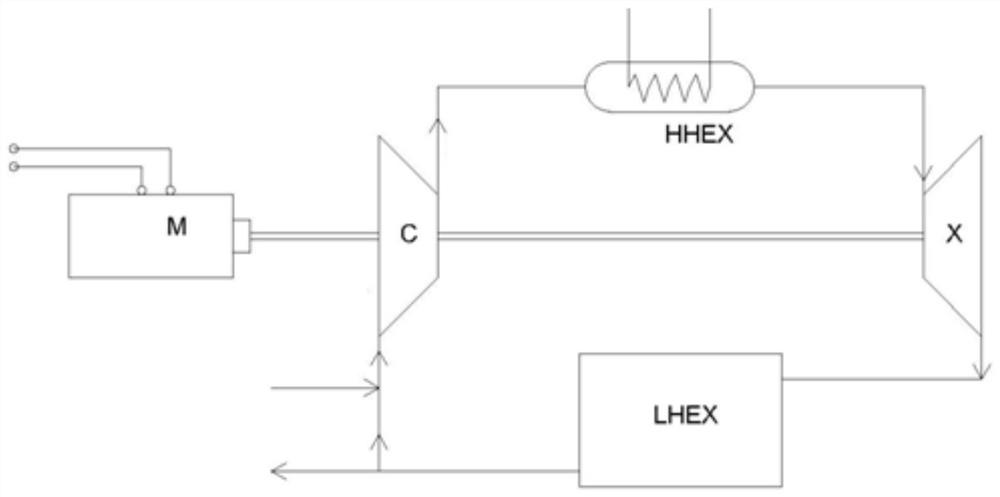

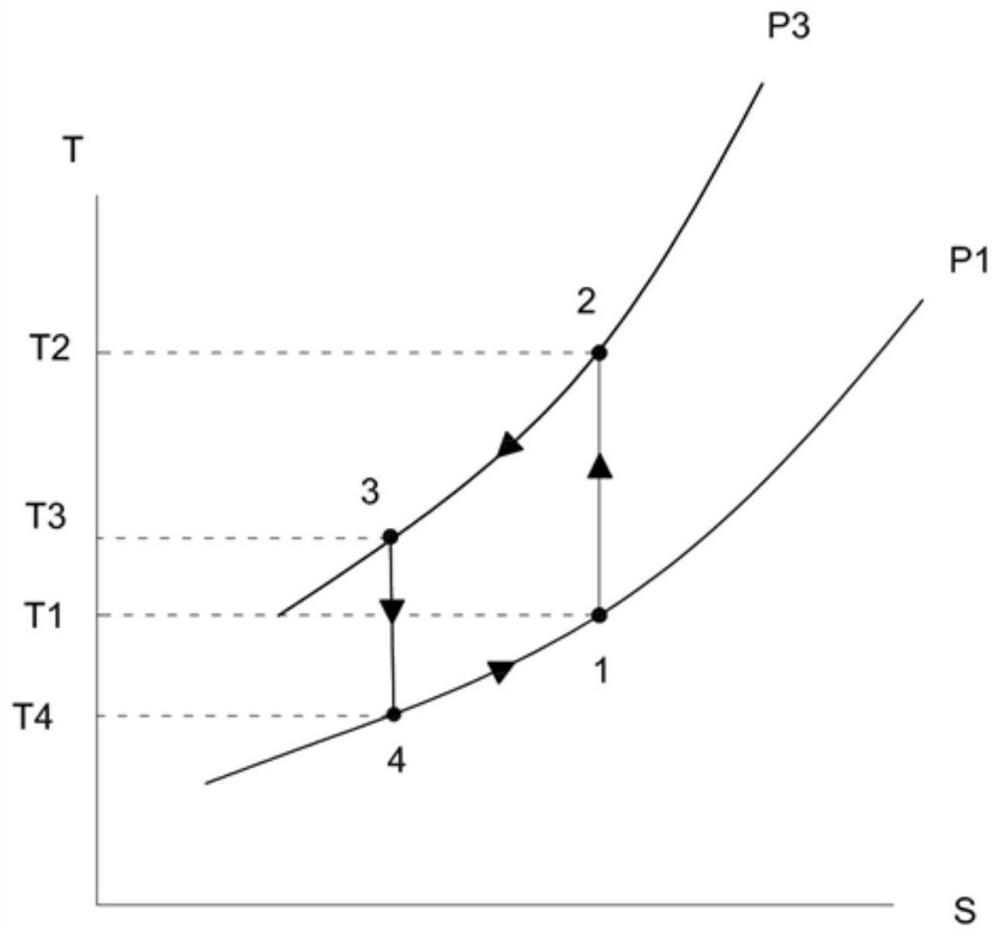

[0049] In this embodiment, see image 3 , the heat pump air conditioner includes a compressor C, a high temperature heat exchanger HHEX and an expander X; the gas output end of the compressor C is connected to the gas input end of the high temperature heat exchanger HHEX, and the high temperature heat exchanger HHEX The gas output end of the compressor C is connected to the gas input end of the expander X, the gas output end of the expander X is connected to the air supply outlet of the air-conditioning space S, and the gas input end of the compressor C is connected to the air-conditioning space S The air return port; the compressor C and the expander X are driven by the motor M. see image 3 , the air return port of the air-c...

Embodiment 2

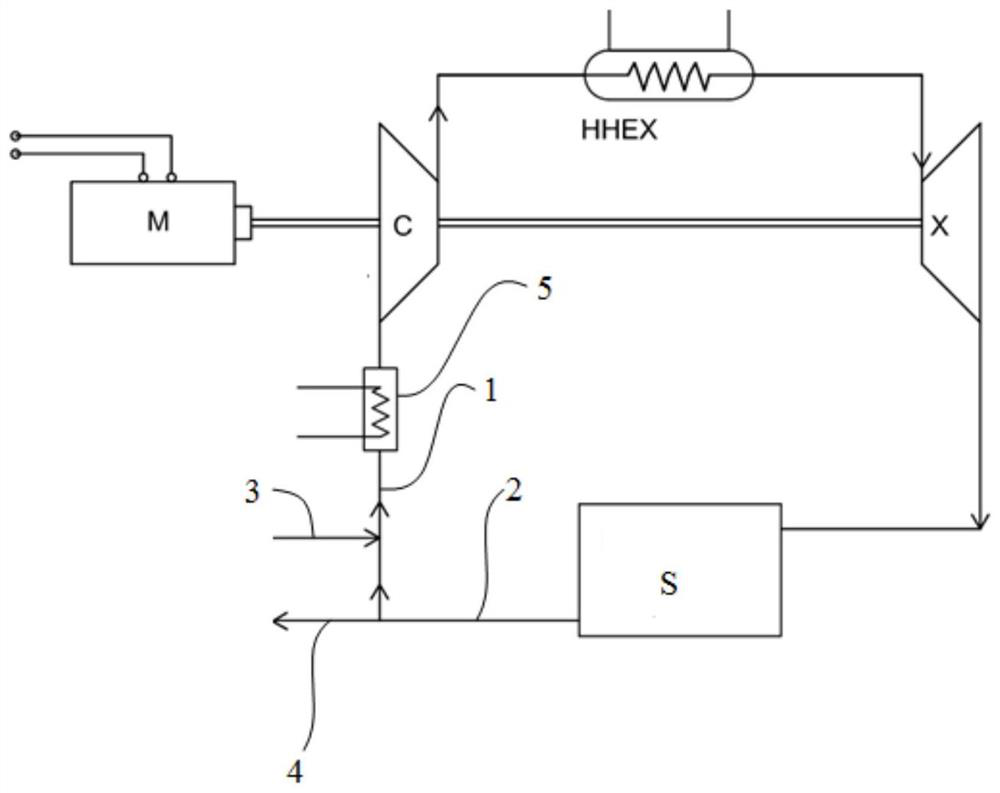

[0067] This embodiment provides a heat pump air conditioner for high-temperature sterilization and sterilization of novel coronavirus in buildings and enclosed spaces. see Figure 4 , the difference between this embodiment and the first embodiment is that the installation position of the heating device 5 is different. Specifically, the gas input end of the heating device 5 is connected to the gas output end of the compressor C, and the gas output end is connected to the high temperature heat exchanger HHEX.

[0068] In this embodiment, the heating device 5 is used for heating the gas flowing out from the gas output end of the compressor C to T2'. Specifically, the mixed gas formed by mixing the fresh air and circulating gas flowing into the return pipe 1 first flows into the compressor C, and is compressed by the compressor C to form a high-temperature and high-pressure gas; the high-temperature and high-pressure gas It flows into the heating device 5, and the heating device...

Embodiment 3

[0071] This embodiment provides a heat pump air conditioner for high-temperature sterilization and sterilization of novel coronavirus in buildings and enclosed spaces. see Figure 5 The difference between this embodiment and the first embodiment is that the pump air conditioner of this embodiment does not include a heating device 5, but a gearbox is added between the compressor C and the motor M. The compression ratio of the compressor C is proportional to the rotational speed, and the compression ratio of the compressor C can be adjusted by controlling the gearbox. The temperature of the mixed gas formed by mixing air and circulating gas) adjusts the compression ratio of the compressor C to ensure that the temperature of the high-temperature and high-pressure gas flowing out of the gas output end of the compressor C can reach an instantaneous sterilization level. requirements, that is, greater than 100 °C.

[0072] For example, when the temperature T1 of the mixed gas forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com