Three-dimensional stress testing device and method suitable for axisymmetric stress condition

A technology of three-dimensional stress and testing device, which is applied in the direction of measuring force components, etc., can solve problems such as unexpected situations of the earth pressure box without consideration, and achieve the effect of compact shape, simple use method and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

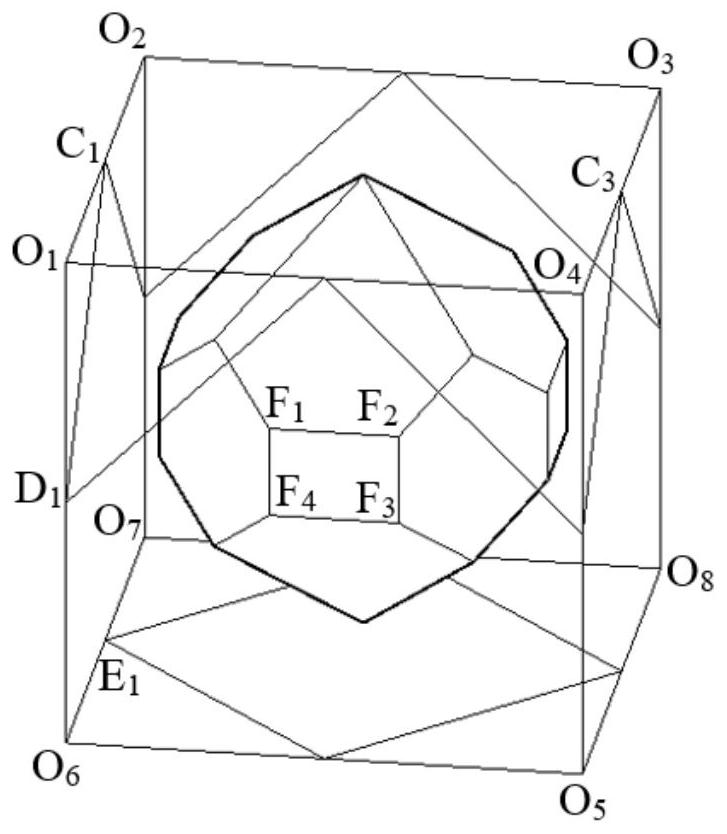

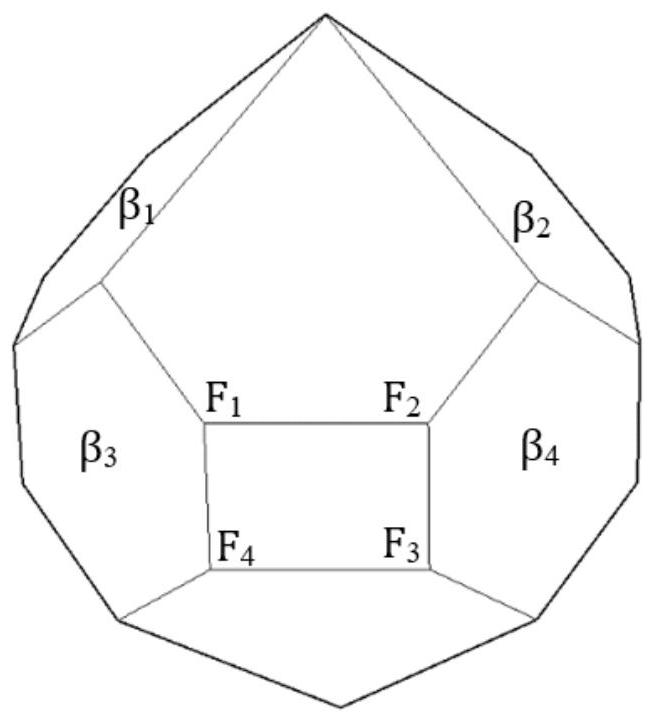

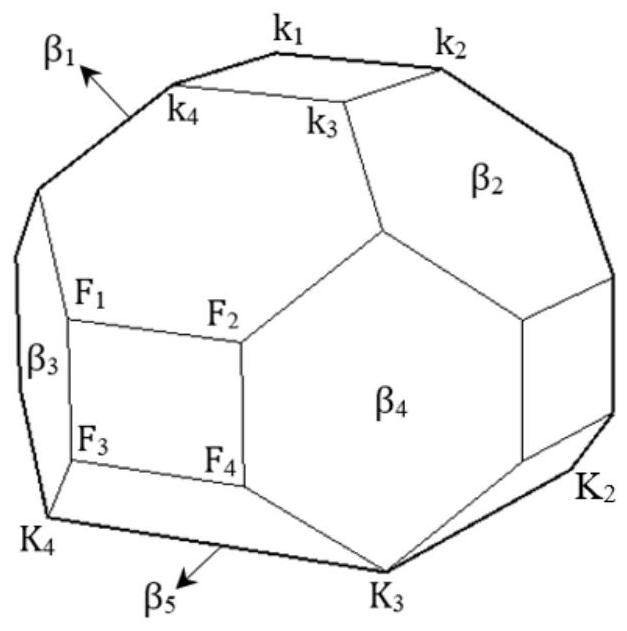

[0048] A three-dimensional stress testing device suitable for axisymmetric stress conditions and its application method of the present invention will be described in detail in conjunction with the accompanying drawings.

[0049] The design principle of the present invention is the stress state theory of a point in space, wherein the stress includes three normal stresses and three shear stresses. Considering the axisymmetric problem, determining the three-dimensional stress state of a point inside the material requires at least four corresponding test elements to be arranged on four surfaces with different normal vectors.

[0050] Such as Figure 6 to Figure 8 As shown, a three-dimensional stress testing device of the present invention suitable for axisymmetric stress conditions includes: a polyhedral base 1 , multiple earth pressure cells 2 , hot melt adhesive 3 and several data wires 4 . The polyhedral base is provided with an earth pressure cell groove 5, a level bubble gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com