Device for processing sandwich-coated-type pet's food

A technology of pet food and processing equipment, which is applied in food science, feed, application, etc. It can solve the problems of pet food particle damage, long time, and reduced product processing and molding speed, so as to reduce the coating time, improve the effect, and improve the packaging quality. overlay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

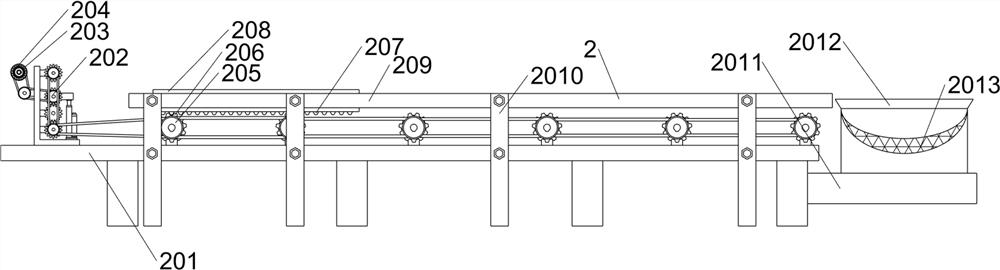

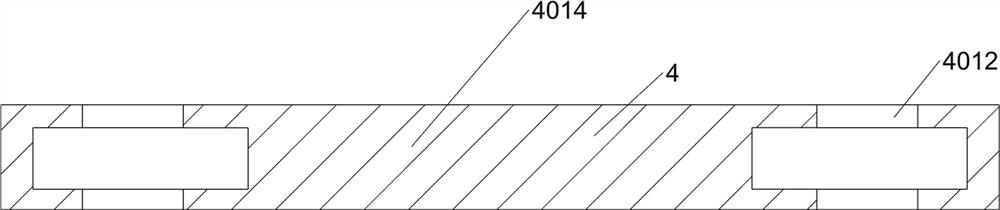

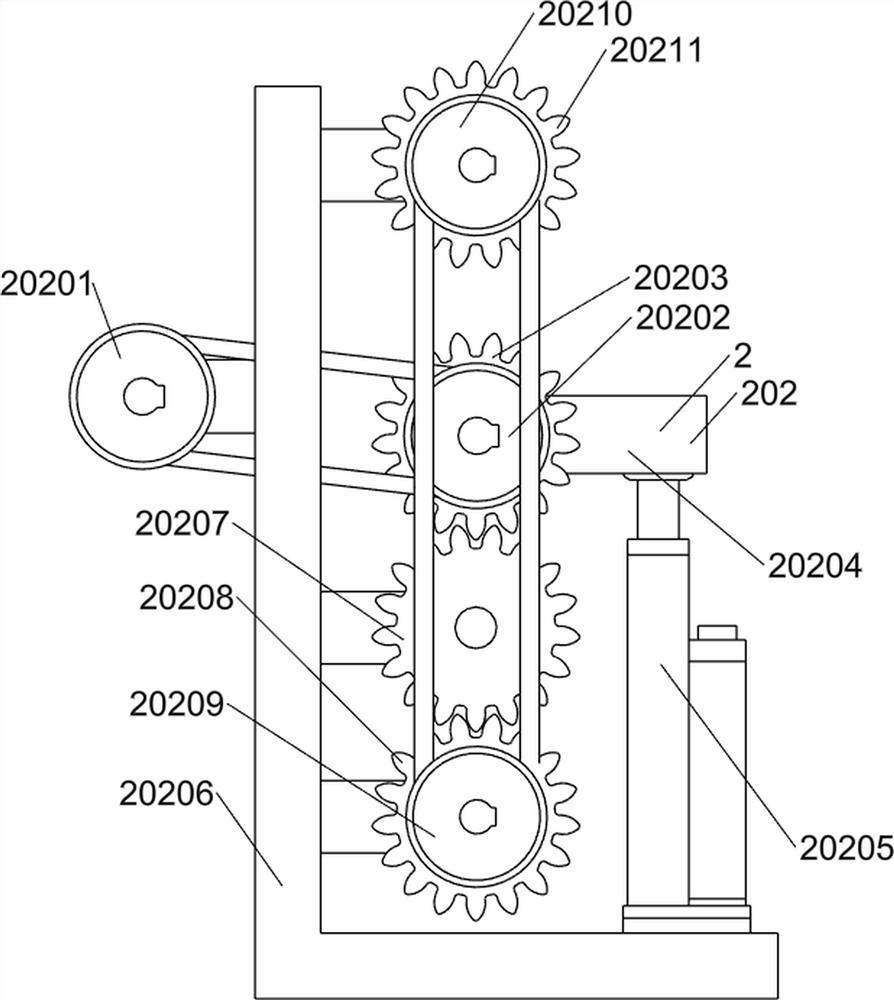

[0029] A sandwich coated pet food processing device, such as Figure 1-9 As shown, including a top frame 1, a material transfer system 2, a layered system 3, a rubber system 4, and a separation system 5; a top frame 1; a material transfer system 2, a material transfer system 2 is connected to a top frame 1; a material transfer system 2 is connected to the lamination system 3; the layout system 3, the layered system 3 is connected to the top frame 1; the lamination system 3 is connected to the rubber system 4; the system 4, the 揉搓 system 4 is connected to the top frame 1 The rubber system 4 is connected to the separation system 5; the separation system 5 is connected to the top frame 1.

[0030] When using this device, the device is placed horizontally at the desired position, an external power source, and the device is integrally prepared by an external control screen. After debugging the device, you first prepare the desired pet food particles and meat. Mud, through the separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com