Local self-heating type condensation removing method for high-voltage switch cabinet

A high-voltage switchgear, self-heating technology, applied in the field of switchgear, can solve the problems of large damage to electrical components, short service life, damage to electrical components, etc., and achieve the effect of reducing condensation phenomenon and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

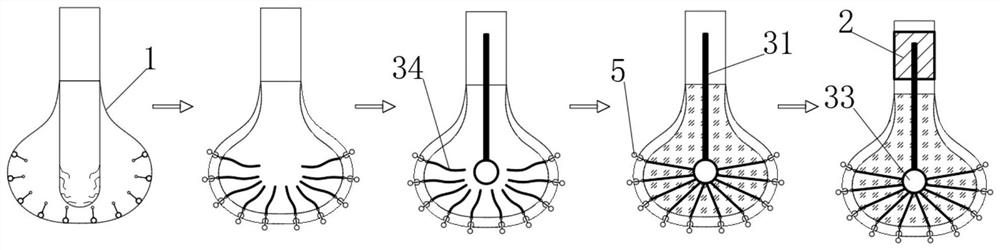

[0044] see figure 1 , a local self-heating high-voltage switchgear decondensation method, comprising the following steps:

[0045] S1. When the temperature is low in winter, first fill the multiple double-layer self-heating bags 1 with high-temperature inert gas, so that the inner layer and the outer layer are squeezed;

[0046] S2. Under the extrusion effect of the inner layer, the moisture-absorbing self-heating rod is extruded to the outside of the double-layer self-heating bag;

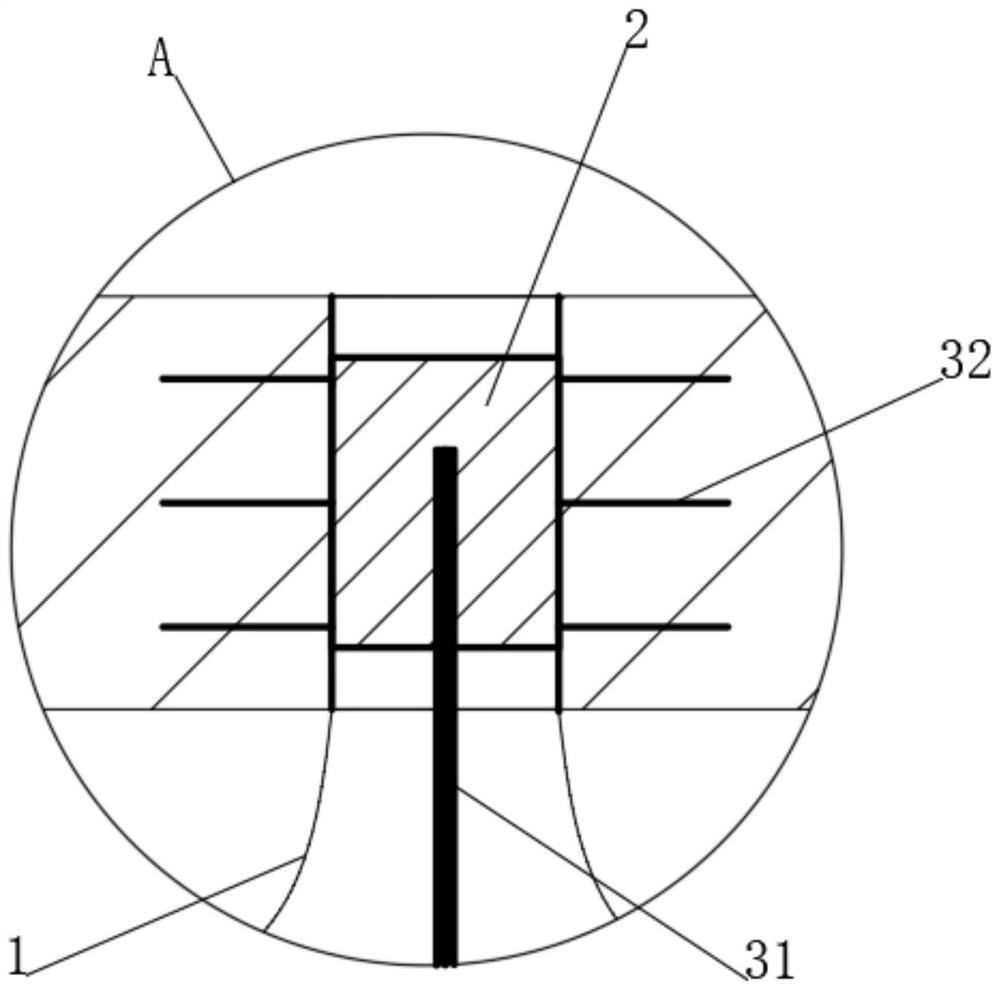

[0047] S3, then inserting the heat-conducting main rod 31 into the inner layer of the double-layer self-heating bag, and filling the interior with heat-storing particles, so as to shape the inner layer of the double-layer self-heating bag;

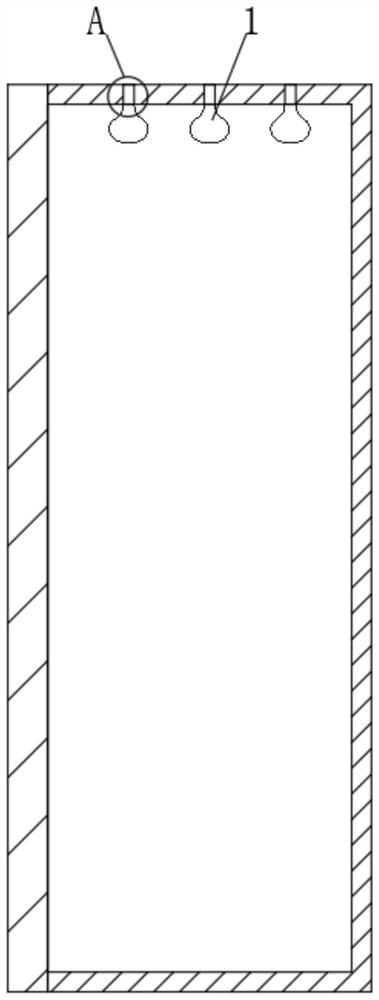

[0048] S4. Insert the heat conduction block 2 at the mouth of the double-layer self-heating bag, and the heat conduction block 2 is in close contact with the inside of the heat conduction hole on the top of the switch cabinet;

[0049] S5. The end of the moi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com