Method for continuously preparing carbon aerogel precursor

A carbon aerogel and precursor technology, which is applied in the field of continuous preparation of carbon aerogel precursors, can solve the problems of inability to meet large-scale production requirements, restricting the mass production of carbon aerogels, and uncontrollable production methods. To achieve the effect of good heat transfer capacity, high production efficiency and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

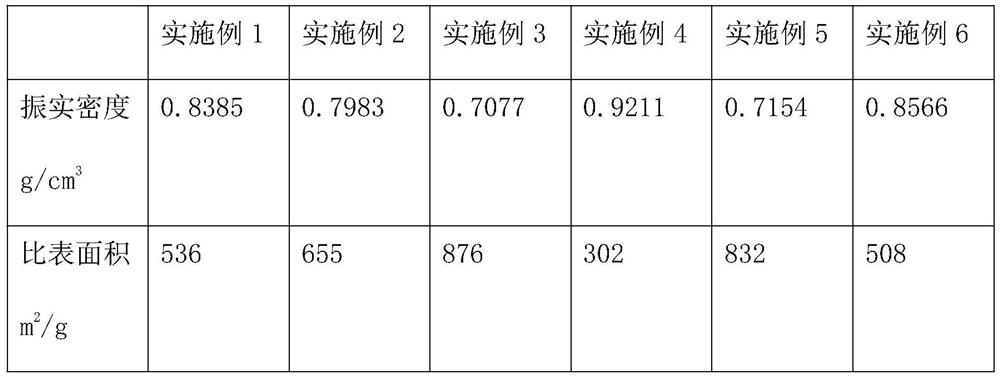

Embodiment 1

[0024] (1) The molar ratio of resorcinol and formaldehyde is 1:1.5, stirred and dissolved at 30° C. to obtain an aqueous solution of an airgel precursor;

[0025] (2) Add the surfactant Span 80 to 15# white oil, stir evenly at 30° C. to prepare a white oil mixture, and Span 80 accounts for 10% of the volume of the white oil mixture;

[0026] (3) Control the flow rate of the precursor aqueous solution to 30ml / min, the white oil flow rate to 10ml / min, the flow ratio to 3:1, and the emulsification pump speed to 1000r / min, so that the two are fully mixed into a suspension in the emulsification pump;

[0027] (4) Preheat the tubular reactor to 80°C in advance, and the suspension goes out of the emulsification pump and directly enters the tubular reactor, and the material flows through the tubular reactor for 10 hours to obtain the precursor white oil slurry;

[0028] (5) Finally, the slurry is subjected to suction filtration, washed with dichloromethane, and then suction filtration...

Embodiment 2

[0030] (1) According to the molar ratio of resorcinol and formaldehyde is 1:2, stirring and dissolving at 20°C to obtain an aqueous solution of airgel precursor;

[0031] (2) Add the surfactant Span 80 to 15# white oil, stir evenly at 20° C. to prepare a white oil mixture, and Span 80 accounts for 20% of the volume of the white oil mixture;

[0032] (3) Control the flow rate of the precursor aqueous solution to 50ml / min, the white oil flow rate to 10ml / min, the flow ratio to 5:1, and the emulsification pump speed to 1000r / min, so that the two are fully mixed into a suspension in the emulsification pump;

[0033] (4) Preheat the tubular reactor to 90°C in advance, and the suspension goes out of the emulsification pump and directly enters the tubular reactor, and the material flows through the tubular reactor for 7.5 hours to obtain the precursor white oil slurry;

[0034] (5) Finally, the slurry was centrifuged, washed with ethanol at 60°C, and then centrifuged to obtain the pr...

Embodiment 3

[0036] (1) According to the molar ratio of resorcinol and formaldehyde is 1:3, stirring and dissolving at 30° C. to obtain an aqueous solution of airgel precursor;

[0037] (2) Add the surfactant Span 80 to 15# white oil, stir evenly at 30° C. to prepare a white oil mixture, and Span 80 accounts for 10% of the volume of the white oil mixture;

[0038] (3) Control the flow rate of the precursor aqueous solution to 30ml / min, the white oil flow rate to 30ml / min, the flow ratio to 1:1, and the emulsification pump speed to 1000r / min, so that the two are fully mixed into a suspension in the emulsification pump;

[0039] (4) Preheat the tubular reactor to 95°C in advance, and the suspension exits the emulsification pump and directly enters the tubular reactor, and the material flows through the tubular reactor for 7.5 hours to obtain the precursor white oil slurry;

[0040] (5) Finally, the slurry is subjected to suction filtration, washed with dichloromethane, and then suction filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com