Efficient welding method and device for arc-assisted laser thin-walled welding titanium pipe

A technology that assists laser and welding methods, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of corrosion resistance decline, no visible, increase of turbulent kinetic energy of fluid in the pipe, etc., and achieve the effect of easy real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

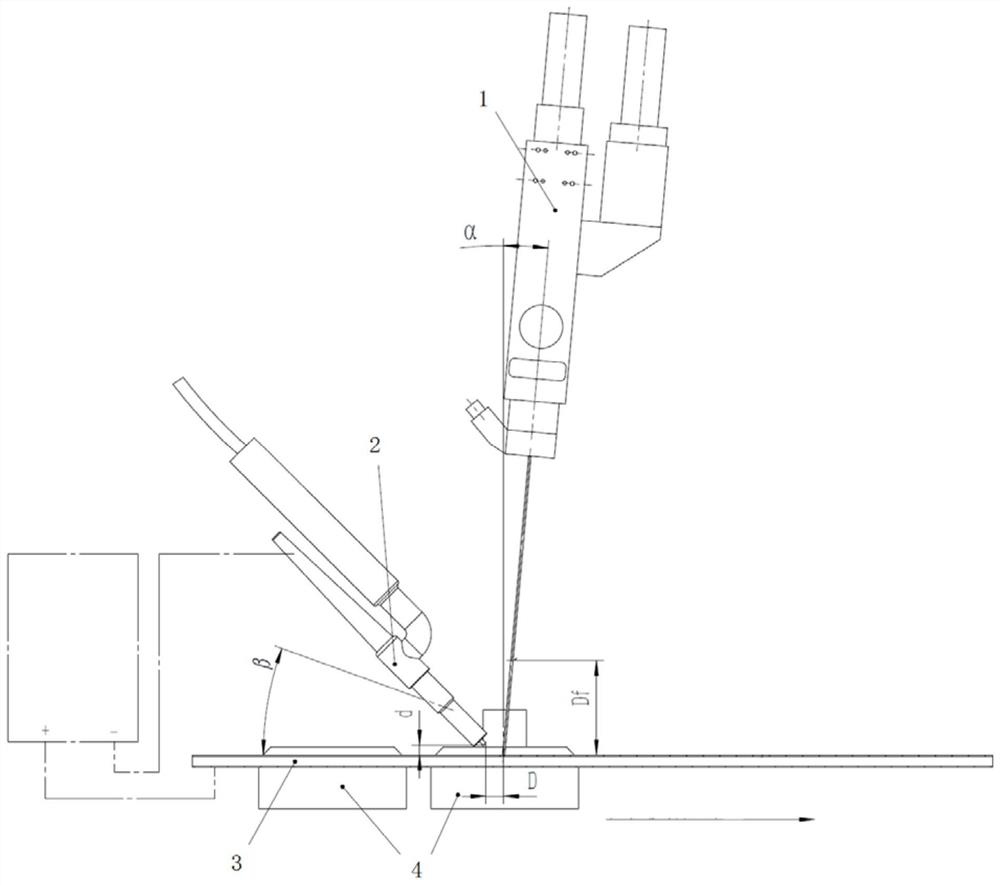

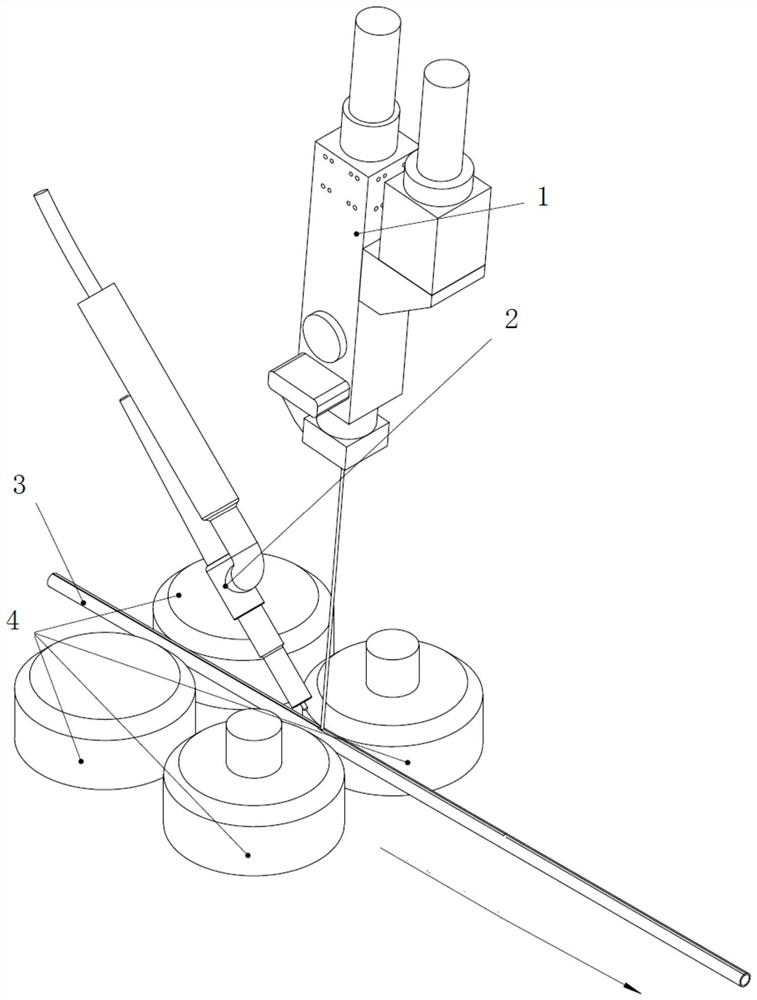

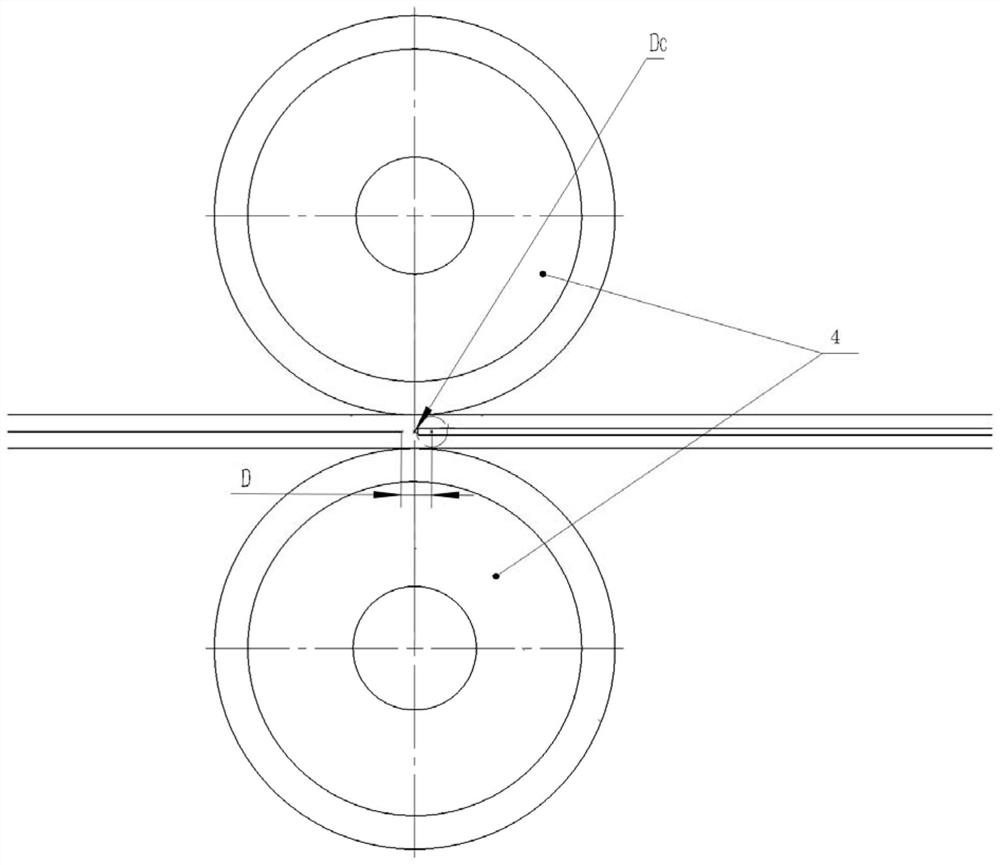

[0058] In combination with the above implementation methods, this embodiment proposes a high-efficiency welding method for thin-walled titanium tubes welded by arc-assisted laser, see Figure 1 to Figure 3 As shown, the laser beam emitted by the welding laser head 1 is used as the main heat source, and the TIG arc generated by the TIG torch 2 is used as the auxiliary heat source. In the axial direction of the titanium tube 3, the butt joint of the circular thin-walled titanium tube 3 is welded linearly without filling.

[0059] see you again Figure 1 to Figure 3 As shown, the welding laser head 1 and the TIG welding torch 2 are located above the butt joint of the welded circular thin-walled titanium tube 3, and the spot center of the laser beam produced by the welding laser head 1 and the TIG welding torch 2 produce The center of the TIG arc is placed on the same welding straight line of the circular thin-walled titanium tube 3 to be welded, so as to perform straight-line we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com