Tree barrier cleaning flying robot with scissor fork type suspension cutter

A technology of flying robots and scissors and forks, which is applied in the direction of unmanned aircraft, aircraft, supporting machines, etc., and can solve problems such as difficult high-altitude tree obstacles, cutting and cleaning, and low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

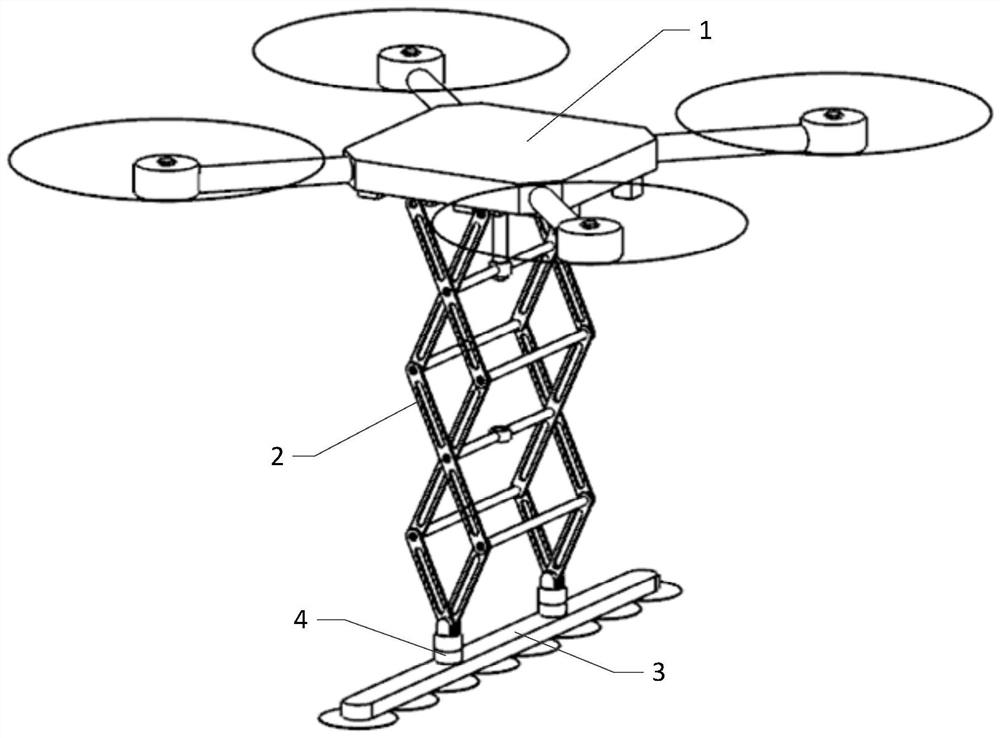

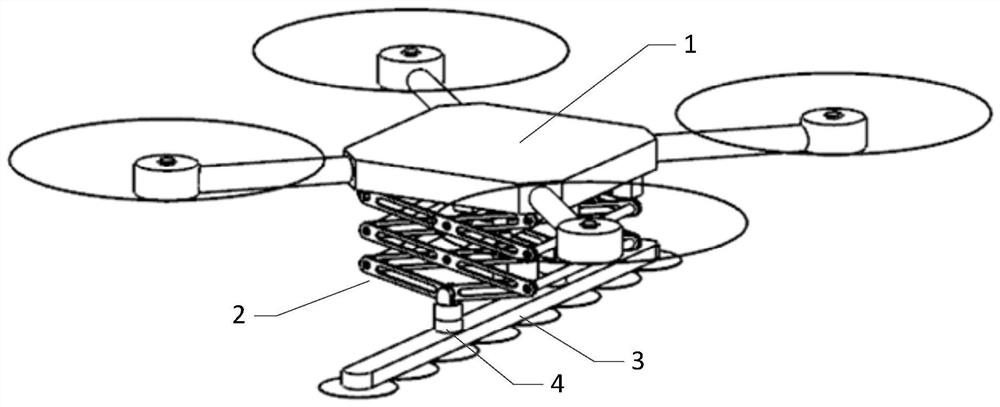

[0095] Embodiment 1: as Figure 1 to Figure 11 Shown, a kind of scissors and fork type hangs the bark clearing flying robot of cutter, comprises flying platform 1, is connected to the suspension mechanism 2 below flying platform 1 and is connected to the cutter system 3 below suspension mechanism 2; Said suspension mechanism 2 comprises Horizontally placed I-shaped frame 211, telescopic device 212 attached to the bottom of I-shaped frame 211, lower connection seat 213 connected to the lower end of telescopic device 212 and docked with tool system 3; said tool system 3 is geometrically symmetrical or An array combination of M (M≥1) chainsaw components arranged in a mass-symmetric manner.

[0096] Preferably, a decoupling device 4 is provided between the suspension mechanism 2 and the tool system 3 to hook or separate the two.

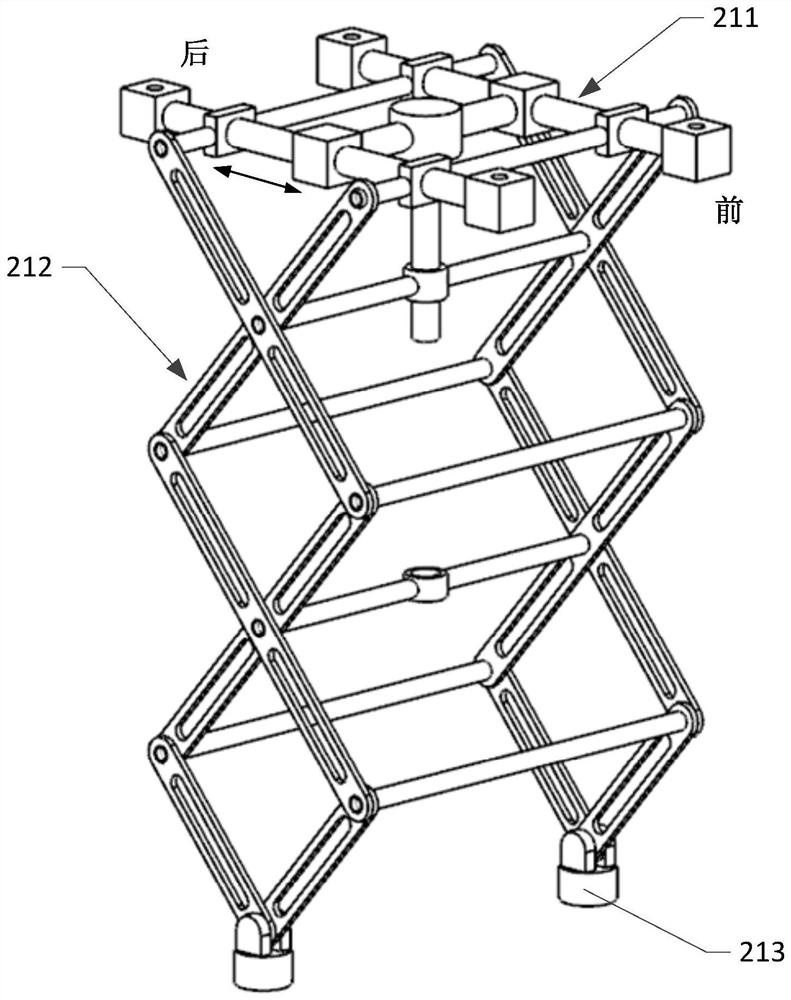

[0097] Preferably, the above-mentioned suspension mechanism 2 is a scissors-fork suspension mechanism: as Figure 4 As shown, the I-shaped frame 211 i...

Embodiment 2

[0145] Embodiment 2: as Figure 12 As shown, a tree obstacle clearing flying robot with scissors and forks hanging knives, the chainsaw described in Embodiment 1 is a chainsaw 3003B, and the chainsaw 3003B includes a guide plate and a chain. Cut outer guide fork 3007. The number N of chain saw components of the chain saw tool system is 2.

Embodiment 3

[0146] Embodiment 3: A scissors-and-fork suspended tree obstacle clearing flying robot, the decoupling device 4 is an electromagnetic decoupling device, including an electromagnet 401 and an armature 402 fixedly connected to the connected parts at both ends of the decoupling device 4 ; The electromagnet 401 is connected with the power supply on the flying robot through a switch.

[0147] Such as Figure 13 As shown, after the electromagnet 401 is energized, it attracts with the armature 402, and the tool system 3 is hooked to the bottom of the suspension mechanism 2; after the magnet 401 is powered off, the armature 402 is released, and the tool system 3 is separated from the suspension mechanism 2. During the obstacle-clearing operation, when the tool system 3 is stuck against the tree barrier and cannot be separated, the tool system 3 can be separated from the flying robot through the uncoupling device 4, thereby implementing safety protection for the flying robot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com