Sapphire single crystal growth method

A growth method, sapphire technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high dislocation density, increased crystal, and reduced service life of graphite materials, so as to reduce dislocation density and improve crystal quality, increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

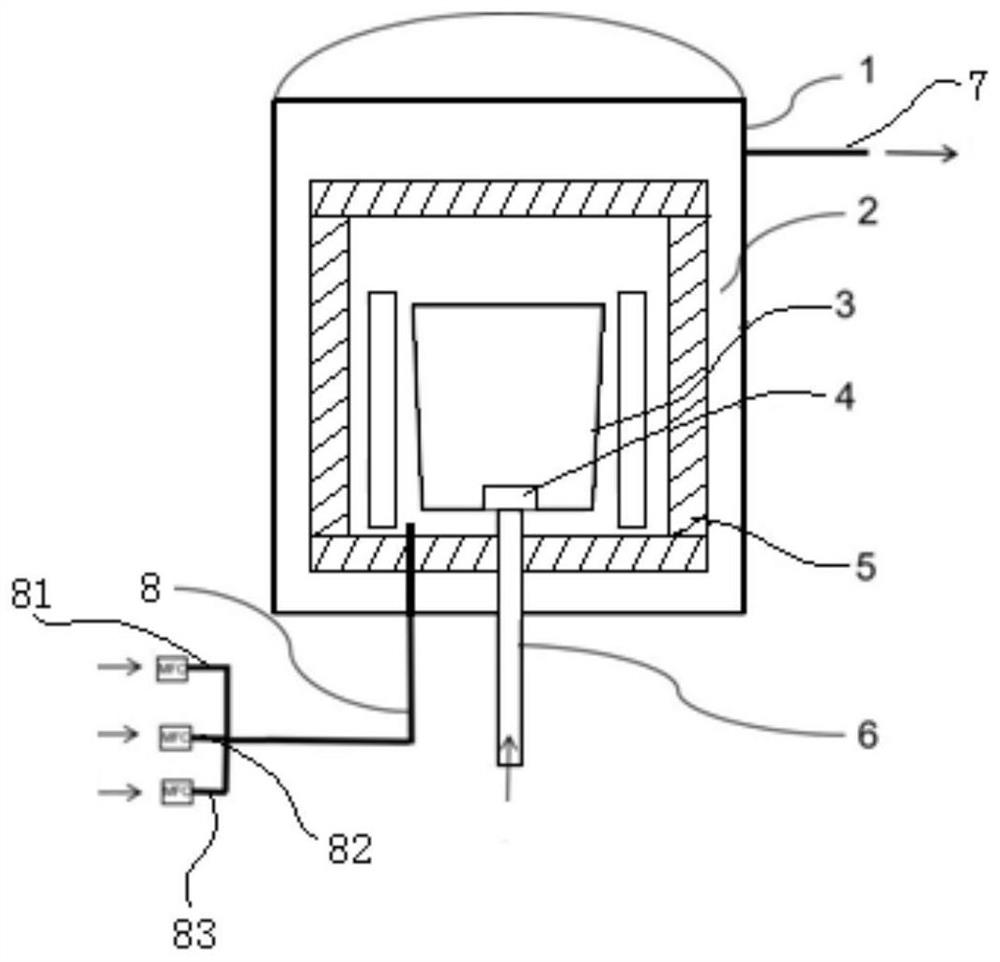

[0037] Sapphire single crystal growth equipment, such as figure 1 As shown, it includes a furnace body 1, a crucible 3, a graphite heater 2, a graphite insulation layer 5, a heat exchanger 6, an air inlet pipe 8 and an air outlet pipe 7.

[0038] The furnace body 1 in this embodiment is stainless steel water-cooled, a cavity is provided in the furnace body 1, the graphite heater 2 is installed in the center of the cavity, the crucible 3 is installed in the center of the graphite heater 2, and the graphite insulation layer 5 is enclosed in the graphite heating Outside the container 2, one end of the heat exchanger 6 is installed at the bottom of the crucible 3, and the other end of the heat exchanger 6 protrudes from the bottom wall of the furnace body 1.

[0039] One end of the air inlet pipe 8 passes through the bottom wall of the furnace body 1 and the graphite insulation layer 5 successively, and one end of the gas outlet pipe 7 passes through the top side wall of the furna...

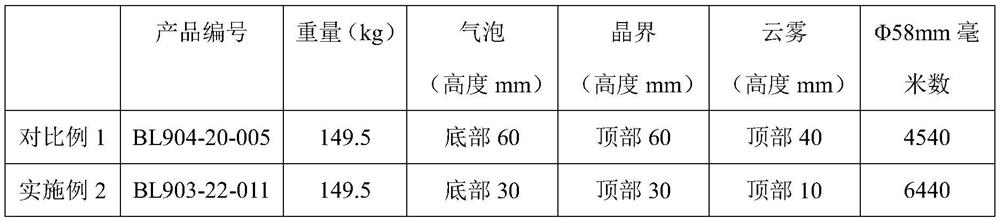

Embodiment 2

[0042] Adopt the sapphire single crystal growth device among the embodiment 1 to grow sapphire single crystal, specifically comprise the following steps:

[0043] (1) 150kg of alumina raw material with a purity of 99.995% or more is steadily filled into the crucible 3 with the seed crystal 4 (sapphire single crystal) stuck, and the crucible 3 is placed on the top of the heat exchanger 6, and the seed crystal is positioned using a positioning device. 4 centers are aligned with heat exchanger 6 centerlines. After cleaning, close the body of furnace 1 and carry out vacuumization degree 10 to the body of furnace 1 -1 Below Pa, start running;

[0044] (2) Vacuum is maintained in the furnace body 1, and the heat exchanger 6 is fed with high-purity helium gas with a purity of more than 99.995%, and the flow rate is 37L / min. At this power level, until the raw material starts to melt;

[0045] (3) After the raw material starts to melt, pass into carrier gas helium, mixed gas carbon ...

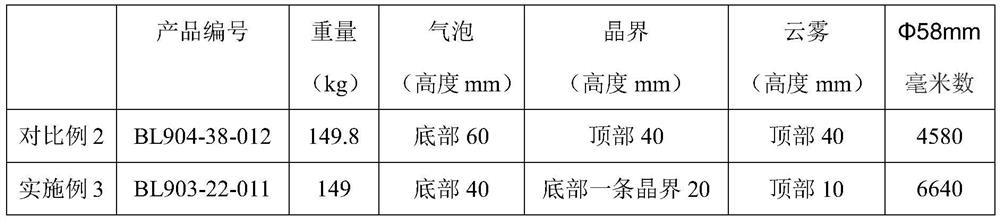

Embodiment 3

[0063] Adopt the sapphire single crystal growth device among the embodiment 1 to grow sapphire single crystal, specifically comprise the following steps:

[0064] (1) 150kg of alumina raw material with a purity of 99.995% or more is steadily filled into the crucible 3 with the seed crystal 4 (sapphire single crystal) stuck, and the crucible 3 is placed on the top of the heat exchanger 6, and the seed crystal is positioned using a positioning device. 4 centers are aligned with heat exchanger 6 centerlines. After cleaning, close the body of furnace 1 and carry out vacuumization degree 10 to the body of furnace 1 -1 Below Pa, start running;

[0065] (2) Vacuum is maintained in the furnace body 1, and the heat exchanger 6 is fed with high-purity helium gas with a purity of more than 99.995%, and the flow rate is 37L / min. At this power level, until the raw material starts to melt;

[0066] (3) After the raw material starts to melt, pass into carrier gas helium, carbon monoxide a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap