Catalyst for preparing maleic anhydride by benzene oxidation and preparation method thereof

A catalyst and co-catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., can solve problems such as poor heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

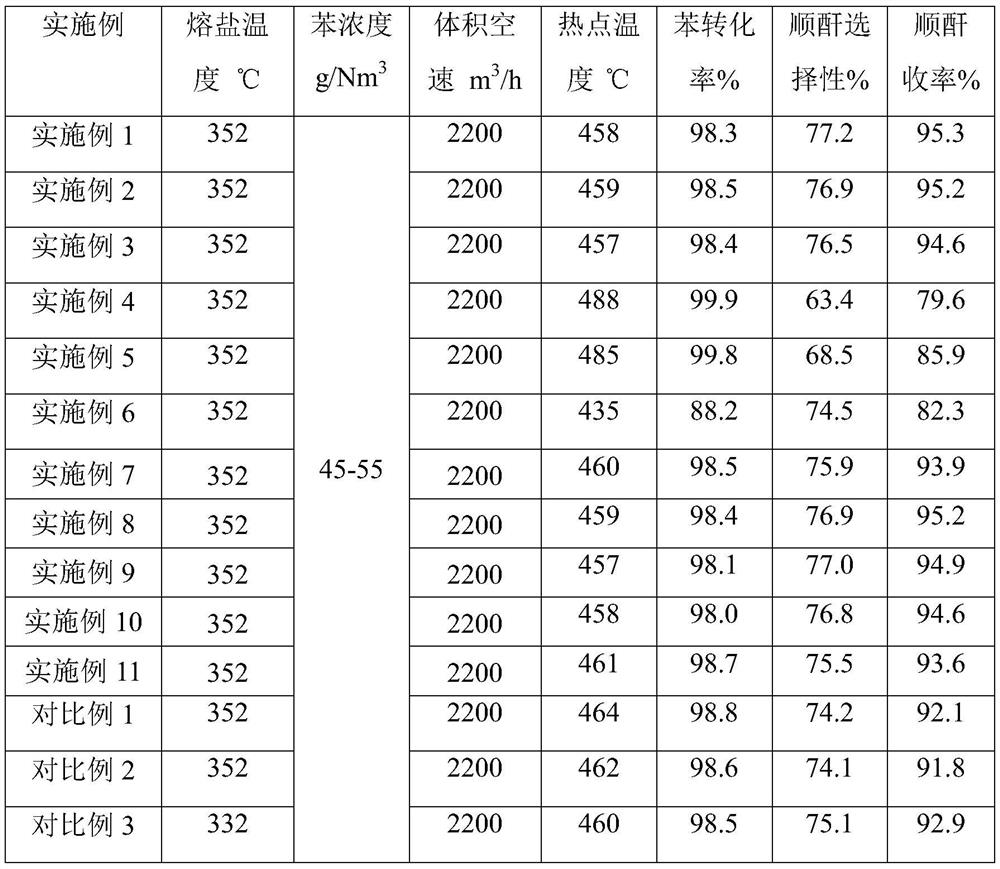

Examples

Embodiment 1

[0106] Step A: Dissolve 98g of oxalic acid in 350mL of water at room temperature, add 67.6g of ammonium metavanadate, and add while stirring until the ammonium metavanadate is completely dissolved to form a dark green solution; dissolve 28.8g of ammonium molybdate in 50mL In water, make it dissolve evenly, and add the solution to the above-mentioned ammonium metavanadate-oxalic acid solution; add 4.3g trisodium phosphate, 1.9g diammonium hydrogen phosphate, 1.5g nickel nitrate, 1.2g cerium nitrate successively under stirring and 1.8g indium nitrate, mixed to prepare the catalyst active component mixture, then add 1.2g of polyethylene glycol, the corresponding addition is 0.2% of the solution quality, continue to stir, and add rod-shaped graphite after the above solution is stirred for ten minutes Alkene, 1 μm in diameter and 2 μm in length, was added in an amount of 3.3 g, and stirring was continued for 30 minutes.

[0107] Step B: Put 330g of the carrier into a rotatable and ...

Embodiment 2

[0111] Step A: Dissolve 98g of oxalic acid in 350mL of water at room temperature, add 67.6g of ammonium metavanadate, and add while stirring until the ammonium metavanadate is completely dissolved to form a dark green solution; dissolve 28.8g of ammonium molybdate in 50mL In water, make it dissolve evenly, and add the solution into the above-mentioned ammonium metavanadate-oxalic acid solution; add 4.3g trisodium phosphate, 1.9g diammonium hydrogen phosphate, 1.5g nickel nitrate, 1.2g cesium nitrate successively under stirring and 2.4g erbium oxide, mix the back and make the catalyst active component mixture, then add the polyoxyethylene glycol of 4.8g, the corresponding addition is 0.8% of solution quality, treat that above-mentioned solution adds spherical nano-graphite after stirring for ten minutes, average The particle size is about 10nm, the added amount is 2.8g, and the stirring is continued for 30 minutes.

[0112] Step B: Put 330g of the carrier into a rotatable and h...

Embodiment 3

[0116]Step A: Dissolve 96g of oxalic acid in 340mL of water at room temperature, add 67.6g of ammonium metavanadate, and add while stirring until the ammonium metavanadate is completely dissolved to form a dark green solution; dissolve 28.8g of ammonium molybdate in 50mL In water, make it dissolve evenly, and add the solution to the above-mentioned ammonium metavanadate-oxalic acid solution; add 4.4g trisodium phosphate, 1.9g diammonium hydrogen phosphate, 1.5g nickel nitrate and 1.2g rubidium nitrate successively under stirring and 2.4g ferric nitrate, mixed to prepare the catalyst active component mixture, then add 3.5g polyethylene glycol, the corresponding addition is 0.6% of the solution quality, after the above solution is stirred for ten minutes, add rod-shaped carbon fibers with a diameter of At about 100nm, the length is 10μm, the added amount is 3.0g, and the stirring is continued for 30 minutes.

[0117] Step B: Put 330g of the carrier into a rotatable and heatable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com