Top jet type waste salt melting furnace

A jet type and melting furnace technology, applied in incinerators, gas fuel burners, combustion methods, etc., can solve the problems of increased energy consumption in waste salt incineration, and achieve the effects of reduced energy consumption, high temperature uniformity, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

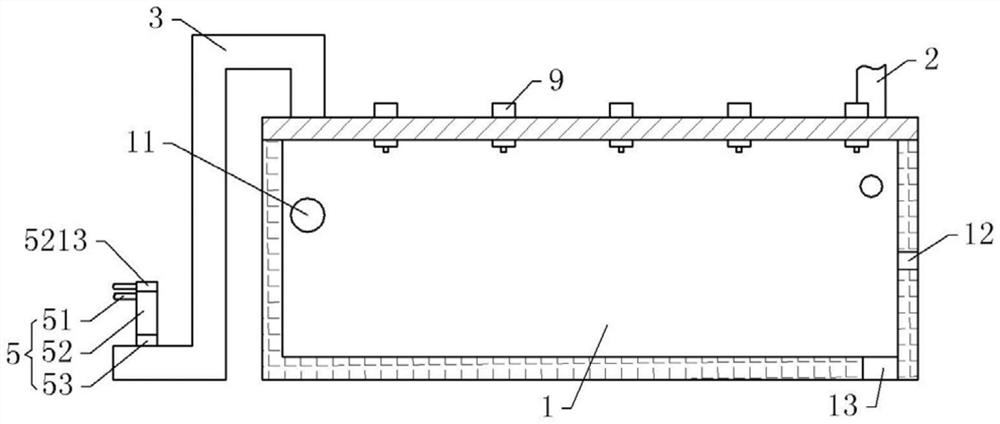

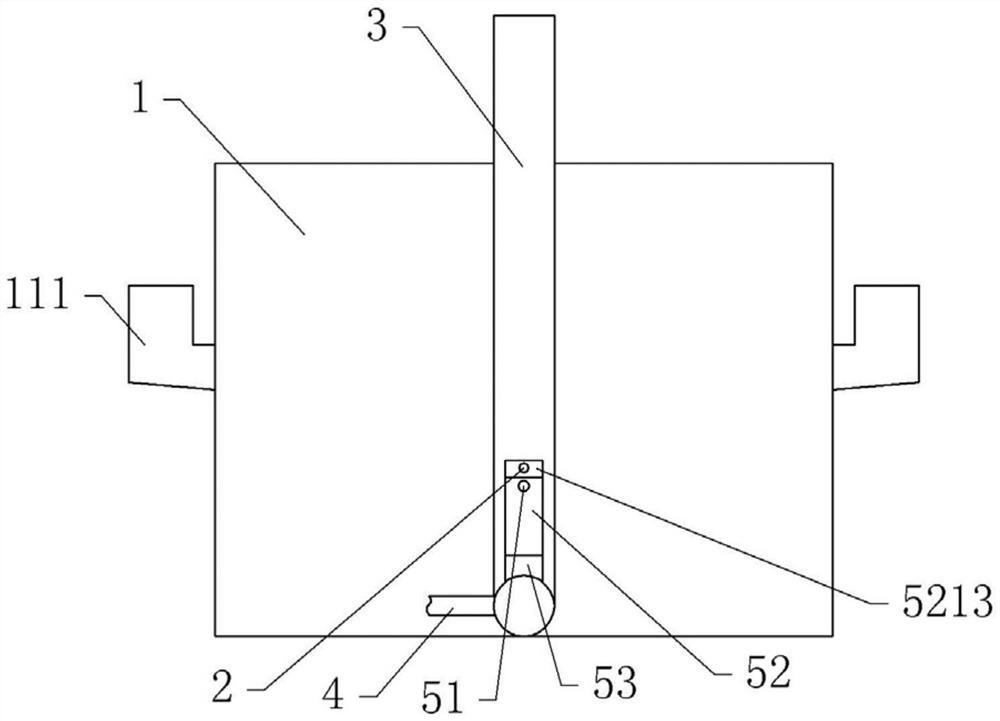

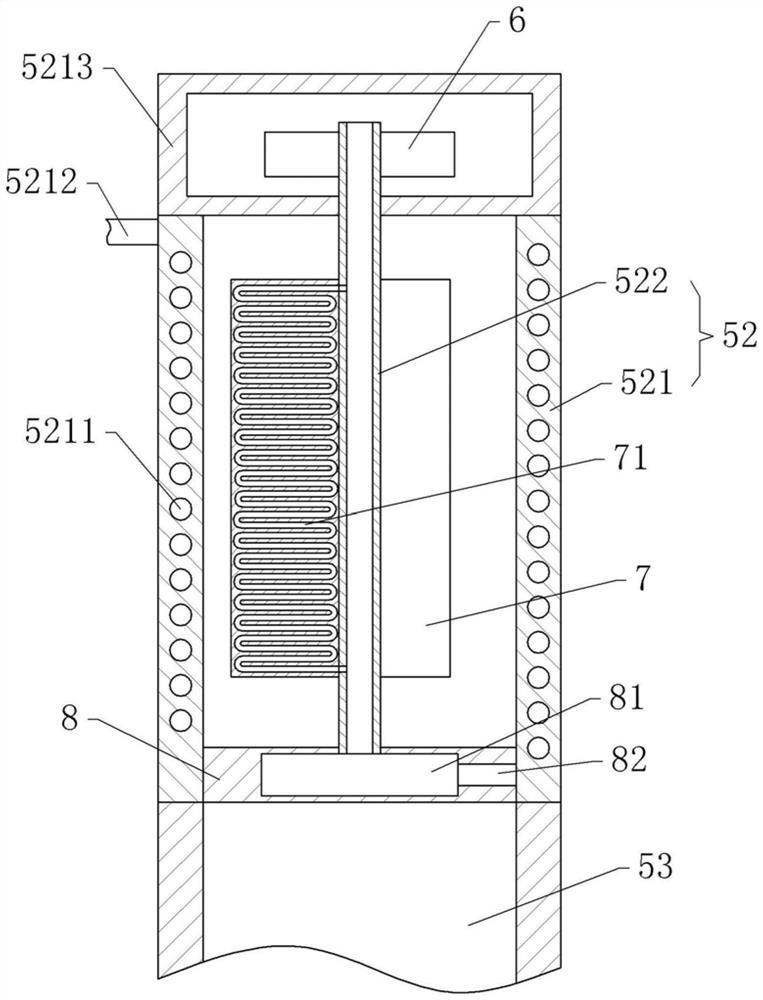

[0037] Top jet waste salt melting furnace, basically as attached figure 1 As shown, the furnace body 1 is included, the left end of the furnace body 1 is the feed end, and the right end of the furnace body 1 is the discharge end. The surroundings and the bottom surface of the furnace body 1 are built by refractory bricks, which can play the role of fire resistance and high temperature resistance when the waste salt in the furnace body 1 is incinerated; the top of the furnace body 1 is provided with a top cover, which can reduce Body 1 loses heat. A plurality of igniters 9 are arranged on the top cover along the length direction (that is, from left to right), and the ignition ends of the igniters 9 are located in the furnace body 1 . The number of igniters 9 is set according to actual needs. In this embodiment, five igniters 9 are provided and evenly distributed on the top cover.

[0038]A feed inlet 11 is provided on the front and rear side walls of the left end of the furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com