Light source stroboscopic detection system and method based on machine vision detection

A technology of machine vision detection and detection system, which is applied in the direction of machine/structural component testing, optical instrument testing, and optical performance testing. Effects of moving trajectory, improving filtering effect, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

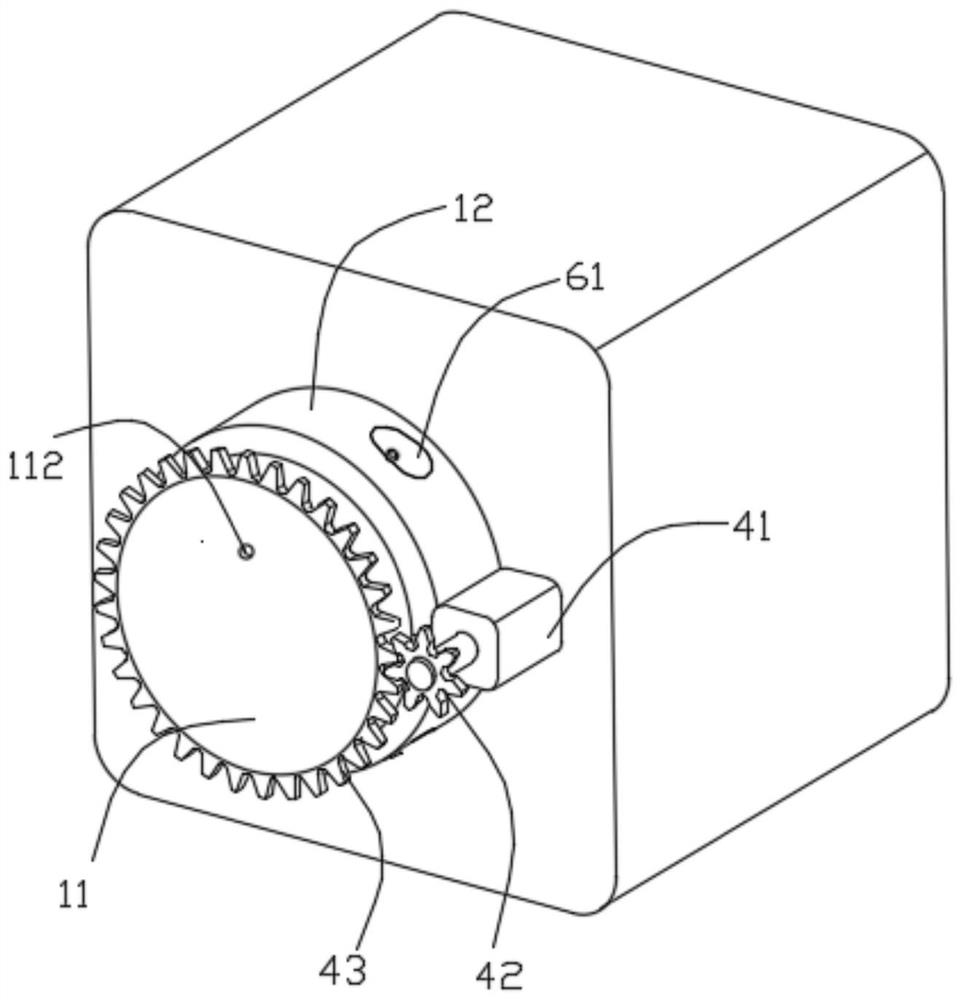

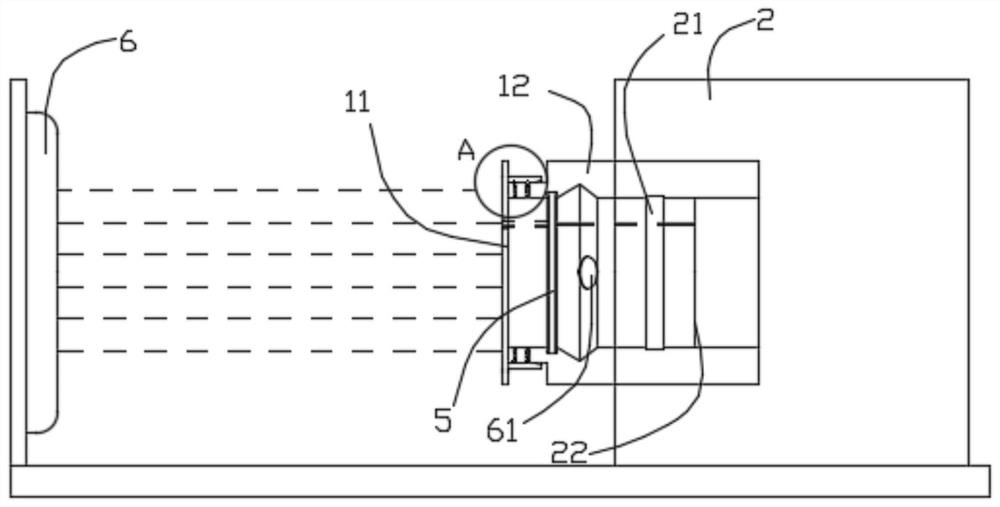

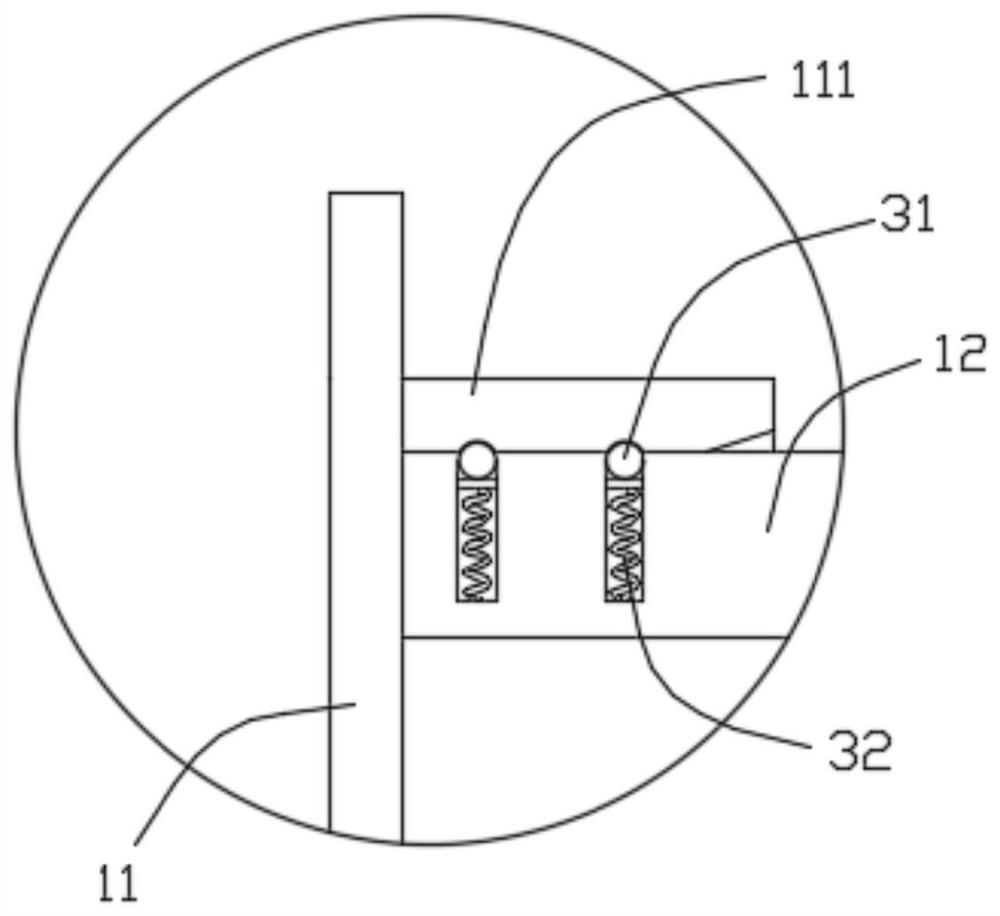

[0040] see Figure 1-11 Shown, the specific embodiment that the present invention provides is as follows:

[0041] A light source stroboscopic detection system based on machine vision detection in this embodiment includes a collection device and a control unit, the collection device is used to collect detection images of the stroboscopic light source to be detected, and the collection device includes a shading mechanism and a camera, The camera is a high-speed camera, which can capture and expose images in a very short time. The shading mechanism includes a shading cover 11 and a shading housing 12; the shading housing 12 is cylindrical along the axis of the camera lens 21. The tail end of the light-shielding housing 12 is connected to the camera body 2, and the free end opposite to the tail end is rotated and matched with the light-shielding cover by setting a rotating part, so that the light-shielding cover is relatively shielded from the central axis of the camera lens. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com