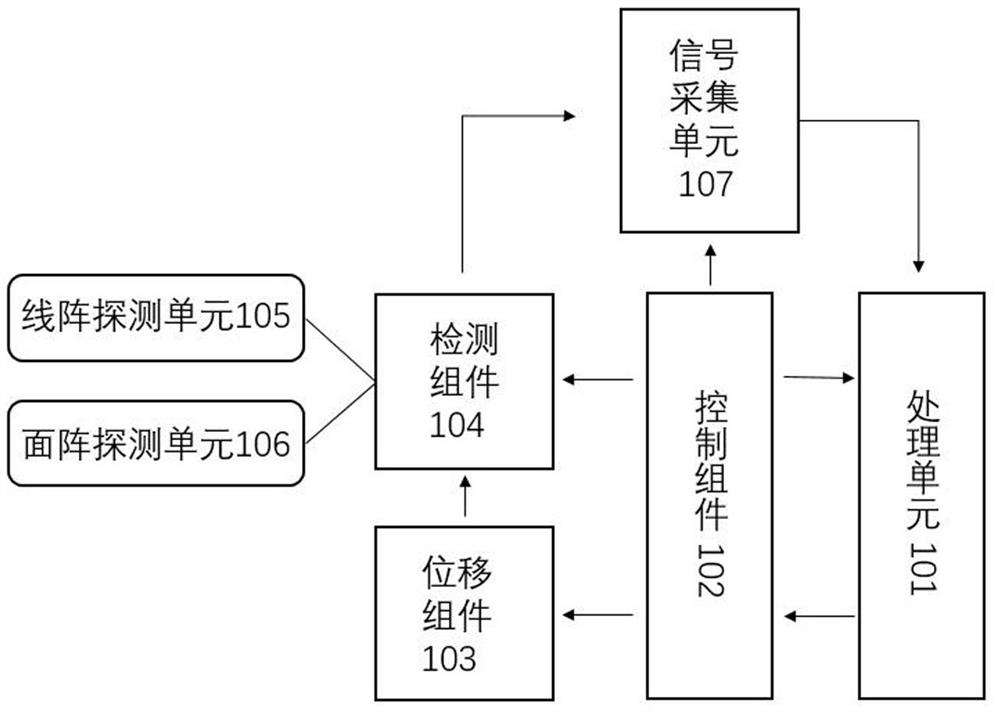

Wafer defect detection system and method

A defect detection and wafer technology, applied in optical testing flaws/defects, measuring devices, material analysis by optical means, etc., can solve problems such as difficult rotation control, difficulty in debugging, inability to meet detection speed, detection accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

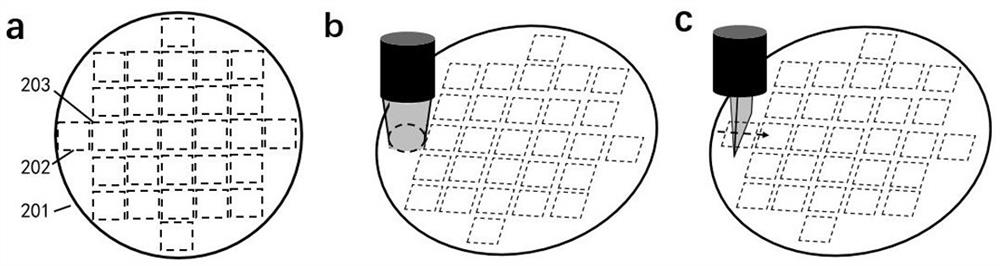

Method used

Image

Examples

Embodiment 2

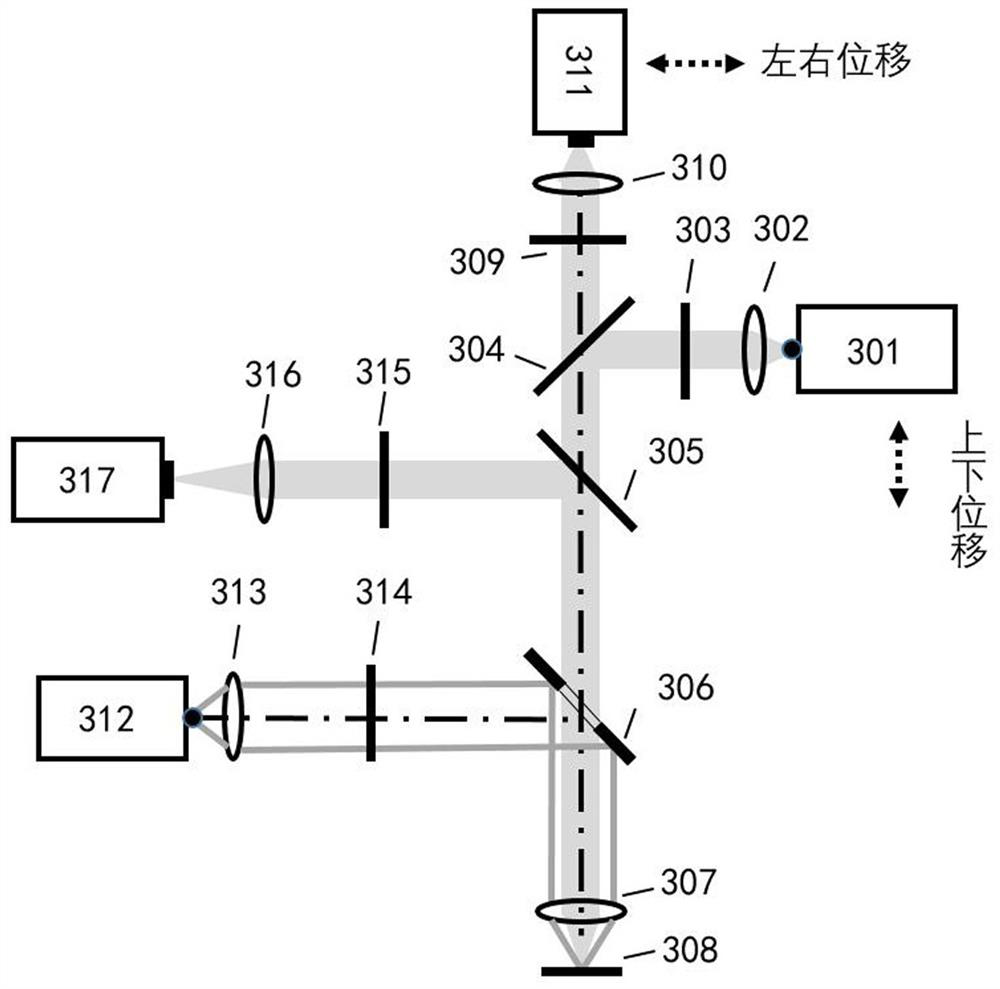

[0031] Another feature different from Embodiment 1 in Embodiment 2 is the addition of a laser focusing module 420, which can monitor the relative position between the detection system and the wafer in real time during the wafer detection process, and drive the detection system to move to ensure that the objective lens is on the sample. It is the focus state, and its working principle is that the beam emitted by the laser focus module 420 is incident on the dichroic mirror 407, and the dichroic mirror 407 is designed to reflect the beam of this wavelength. The beam passes through the normaski prism 408 and is converged on the wafer 410 by the objective lens 409. The focused beam reflected by the wafer returns to the original path and is received by the focusing module 420 after passing through the objective lens 409, the normaski prism 408, and the dichroic mirror 407. At this time, it can be judged whether the objective lens is in focus according to the characteristics of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com