Data inspection method and device for operation and maintenance system

An operation and maintenance system and data technology, applied in manufacturing computing systems, data processing applications, and other database retrievals, can solve problems such as inability to guarantee the accuracy and validity of collected data, difficulty in finding power plant problems, and inaccurate processing results. Achieve the effects of strong inclusiveness, accuracy assurance, and expansion of processing scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

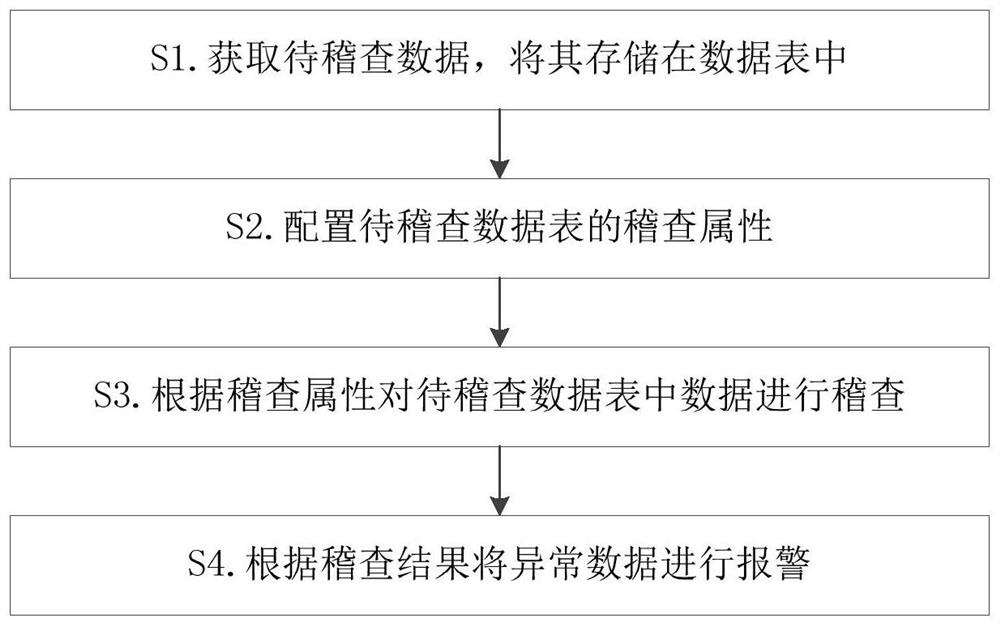

[0043] like figure 1 As shown, the present invention is a data inspection method of an operation and maintenance system, and the method is specifically:

[0044] S1. Obtain the data to be audited and store it in the data table;

[0045] S2. Configure the audit attributes of the data table to be audited;

[0046] S3. Audit the data in the data table to be audited according to the audit attributes;

[0047] S4. Alarm the abnormal data according to the inspection result.

[0048] In the present invention, the proposed operation and maintenance system is a system that collects site operation and dynamic environment data in real time. It uses the Internet and big data technology to collect, analyze and process the data of the power plant, and records abnormal data. The environment is monitored. In the operation and maintenance system, data analysis requires data inspection, but the amount of data collected by the power plant is very large, and the data types are different. If a...

Embodiment 2

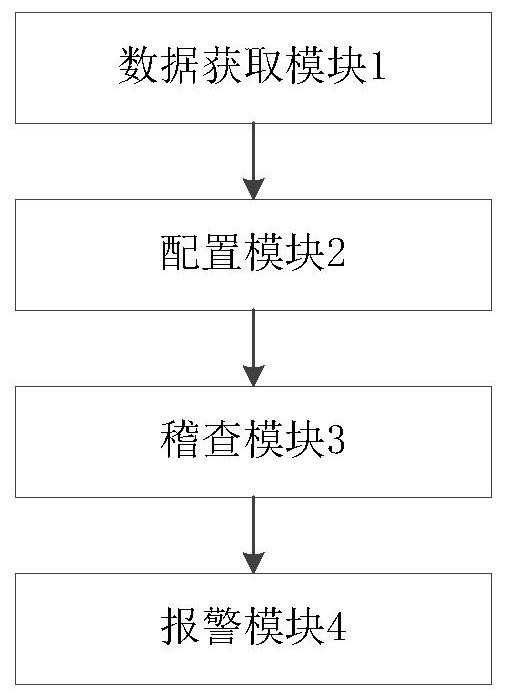

[0063] like figure 2 As shown, the present invention provides a data inspection device for an operation and maintenance system, including:

[0064] Data acquisition module 1; the data acquisition module is used to obtain the data to be inspected and store it in the data table;

[0065] Configuration module 2: the configuration module is used to configure the audit attributes of the data table to be audited;

[0066] Audit module 3: the audit module is used to check the data in the data table to be audited according to the audit attributes;

[0067] Alarm module 4: the alarm module is used to alarm abnormal data according to the inspection results;

[0068] The data acquisition module 1 is connected to the configuration module 2 , the configuration module 2 is connected to the inspection module 3 , and the inspection module 3 is connected to the alarm module 4 .

[0069] The data acquisition module 1 is used to obtain the data to be audited and store it in the data table; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com