Lyophilized formulation sealed in glass vial

A technology for glass containers and preparations, which is used in medical containers, freeze-dried transportation, and medical preparations with inactive ingredients, etc., can solve problems such as poor appearance of vials, affecting quality inspection, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

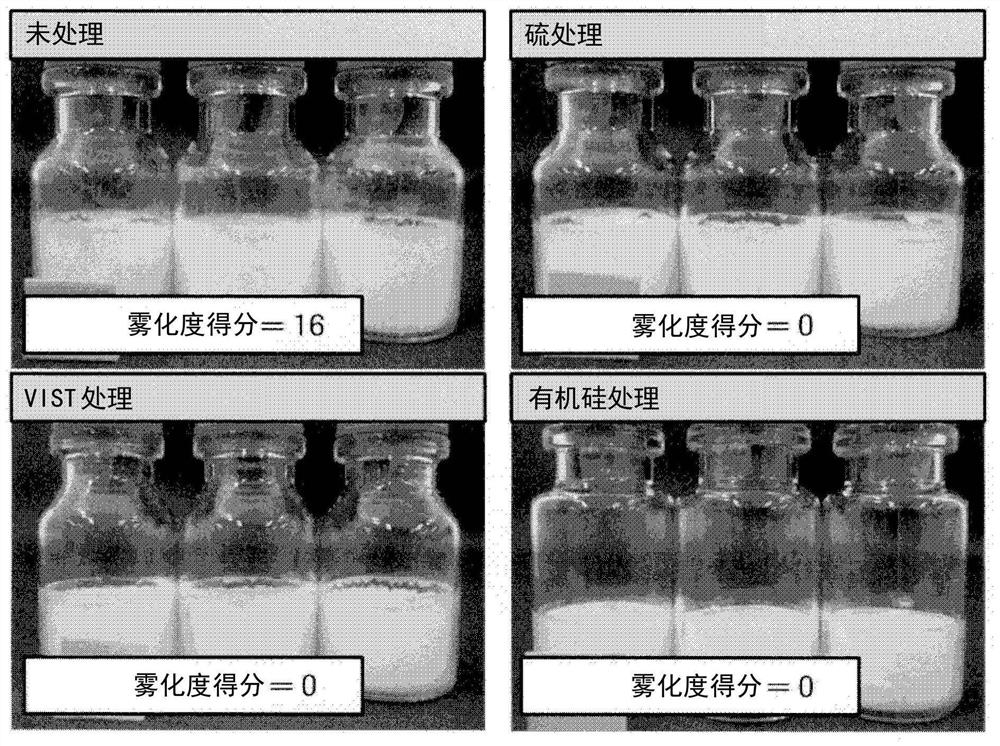

[0175] Example 1: Effect of Suppressing Glass Vial Atomization by Sulfur Treatment or VIST Treatment

[0176] The degree of fogging on the inner surface of the glass container was evaluated when the protein-containing drug solution was placed in sulfur-treated, VIST-treated, silicone-treated or untreated glass vials, and freeze-dried.

[0177] The vials used were as follows: vial 10 mL white bulk (material: borosilicate glass; without any treatment; manufactured by Murase Glass Co., Ltd.); vial 10 mL white sulfur bulk (material: borosilicate glass; treated with sulfur; manufactured by Murase Glass Co., Ltd.), 10 mL of VIST vial (material: borosilicate glass; VIST-treated; manufactured by Daiwa Special Glass Co., Ltd.), and 10 mL of TopLyo (registered trademark) vial (material: borosilicate glass; Silicone treatment; manufactured by SCHOTTAG). The vials were dry heat sterilized at 250°C for 120 minutes prior to use.

Embodiment 2

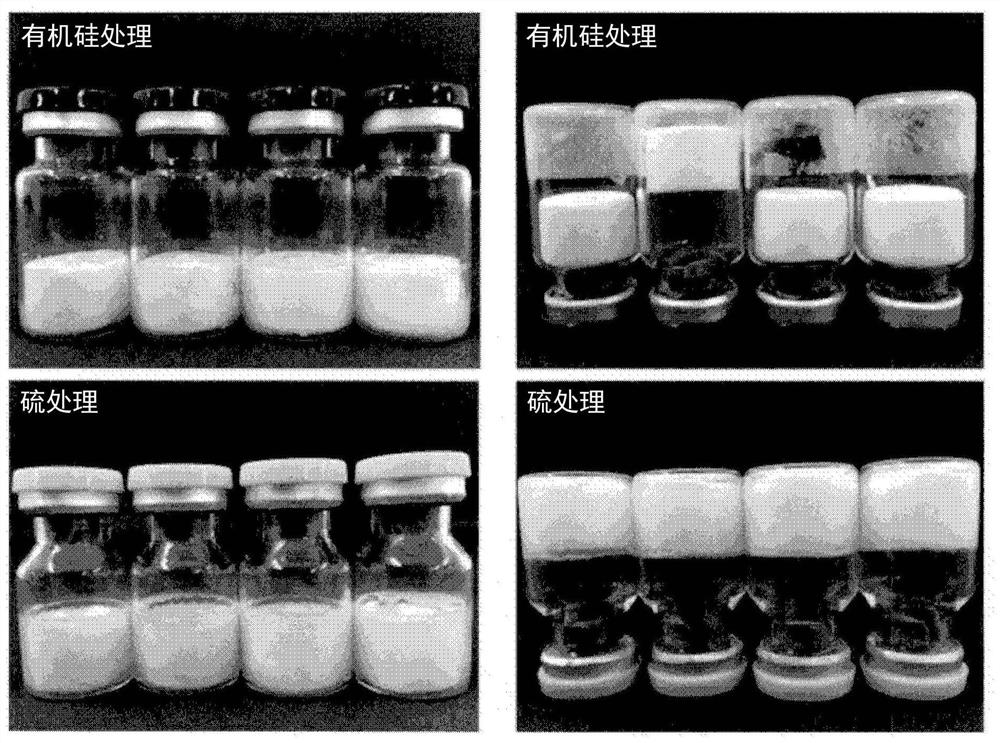

[0201] Example 2 No Cake Shrinkage in Sulfur-Treated Vials and VIST-Treated Vials

[0202] For the vials subjected to various surface treatments, freeze-dried preparations were prepared in the same manner as in Example 1, and the state of the cake was evaluated.

[0203] The result is as figure 2 shown. In the silicone-treated vials, the cake was found to shrink during freeze drying, creating a void between the container wall and the cake, allowing the cake to move easily in the vial. On the other hand, good cake formation was achieved without cake shrinkage in sulfur-treated and VIST-treated vials (data not shown). If the cake is easy to move, physical stress at the time of transportation, etc. may cause the cake to disintegrate, resulting in a decrease in quality. Thus, it has been demonstrated that sulfur-treated vials and VIST-treated vials inhibit aerosolization and form a good cake when freeze-dried, thus outperforming silicone-treated vials.

Embodiment 3

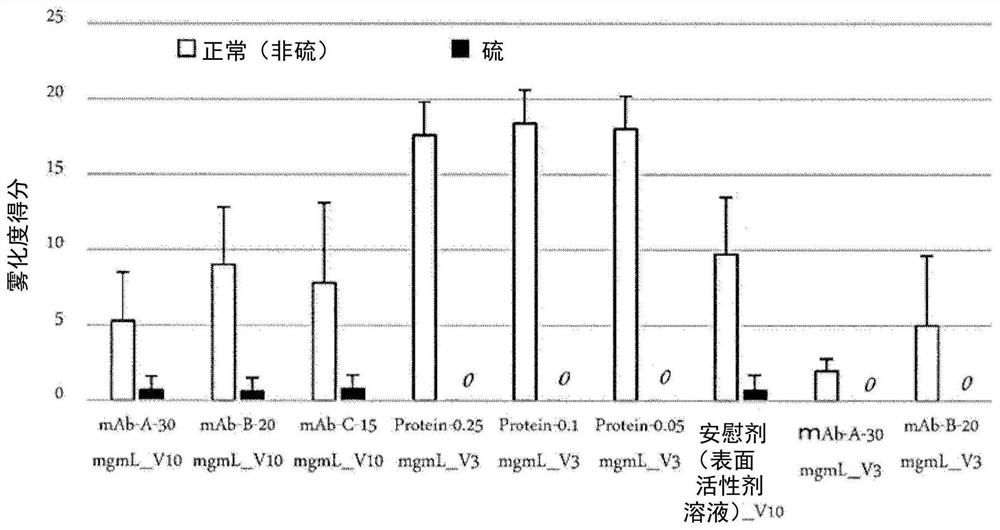

[0204] Example 3 Evaluation of the atomization degree of freeze-dried products obtained by sealing various chemical solutions in various surface-treated vials Score and Pie Move Ratio

[0205]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com