Process for the purification of hydrogen cyanide

A hydrogen cyanide and logistics technology, applied in the preparation/purification/separation of hydrogen cyanide, chemical instruments and methods, cyanide, etc., can solve the problems of no inhibition and reduction of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

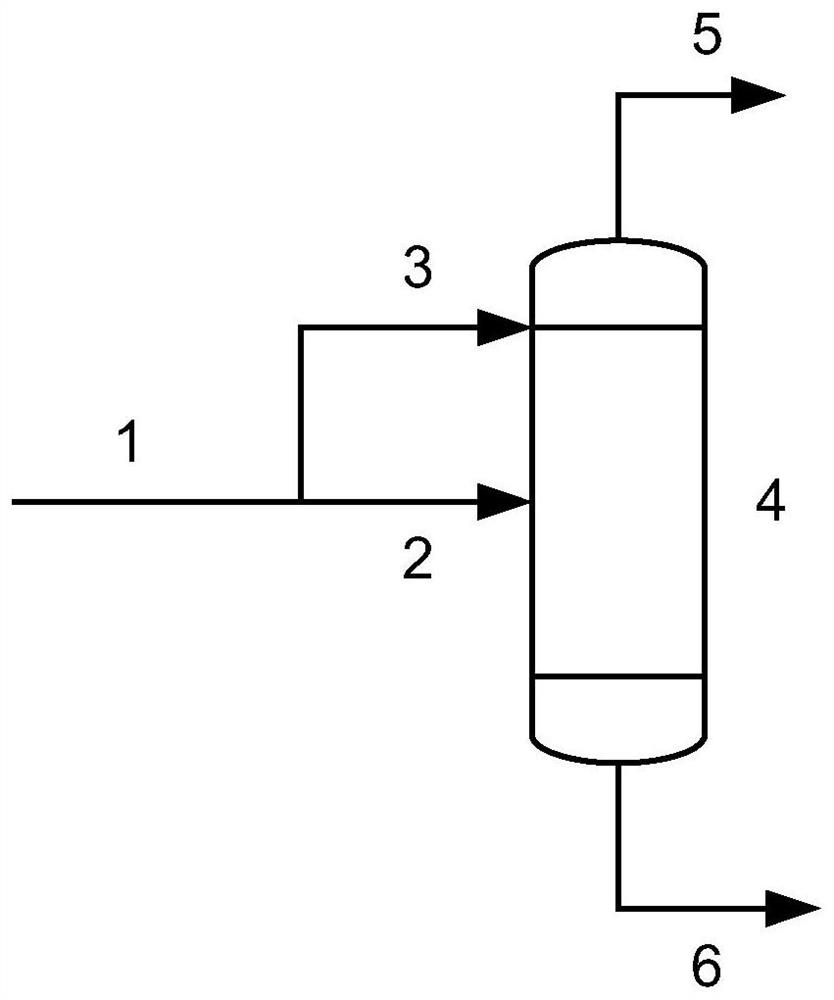

[0078] Purification of a hydrogen cyanide stream comprising hydrogen cyanide according to the invention

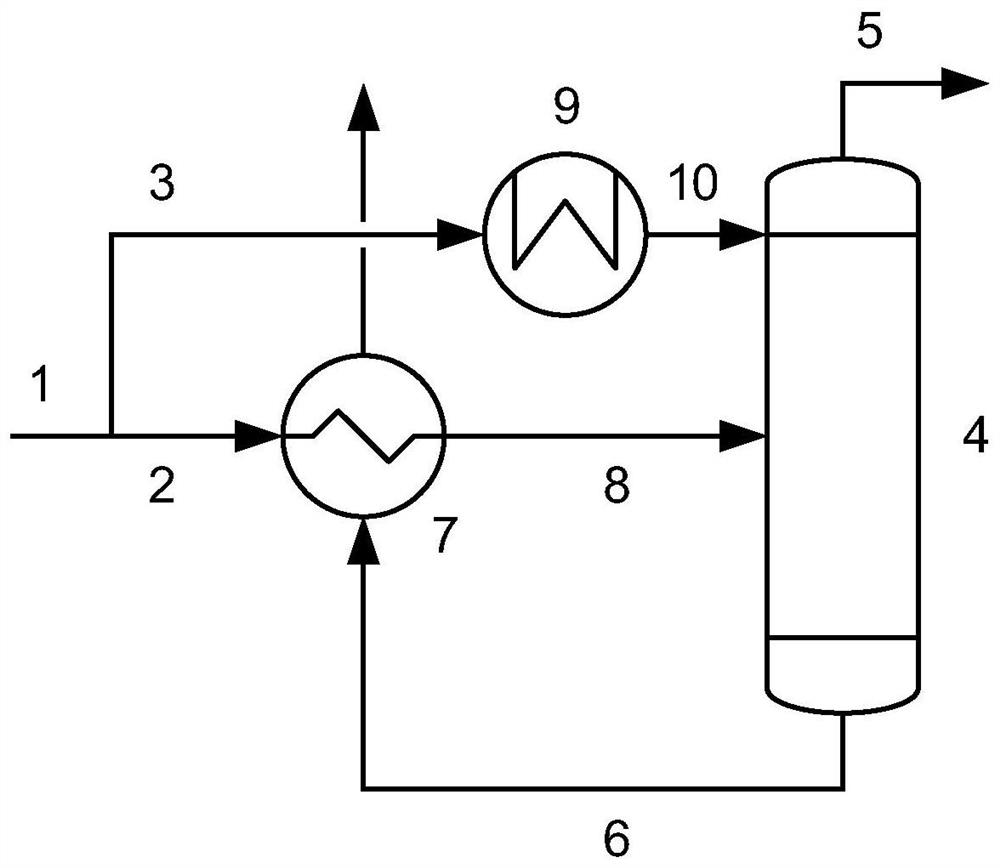

[0079] Using the modeling software Aspen against figure 2 The distillation process shown simulates the purification of a hydrogen cyanide-containing stream: the aqueous feed stream (1) from the HCN absorber containing 4-5% by weight hydrogen cyanide is divided into a first liquid stream (2) and a second liquid stream (2). Two liquid streams (3). Stream (2) is heated in heat exchanger (7) to a temperature of 92°C by heat exchange with bottom stream (6) from distillation column (4) to obtain heated stream (8). Said stream (8) is introduced between the 7th and 10th tray of a distillation column (4) having 20 trays. The cooled bottom stream ( 11 ) thus obtained, which mainly comprises water, is recycled to the HCN absorption column. Stream (3) is introduced at the top of distillation column (4) at a temperature of 24.9°C. An overhead vapor stream (5) rich in hydrogen cy...

Embodiment 2

[0087] Comparison with prior art steps

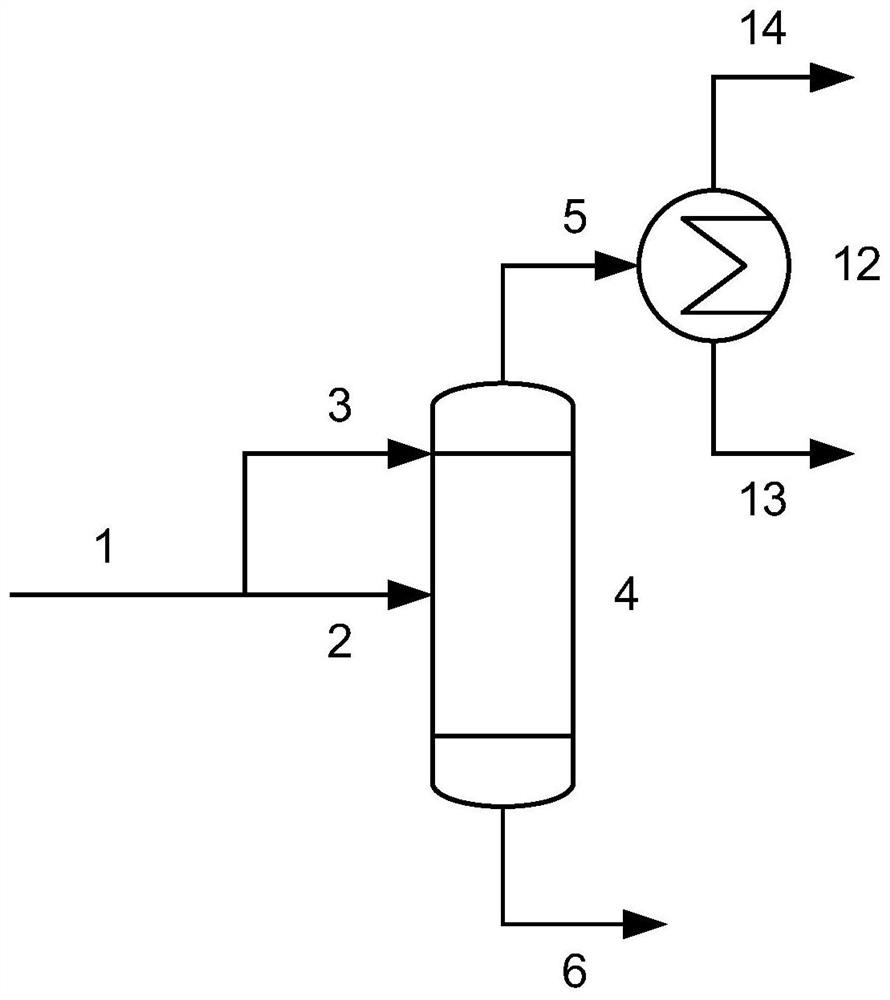

[0088] In this example, the Figure 5 The results shown for the purification of a stream comprising hydrogen cyanide in a prior art distillation process (experimental data) are compared with those of a stream comprising hydrogen cyanide in a process according to the invention (using Aspen The simulated data for figure 2 methods shown) were compared. In order to compare the operating parameters of the two processes, the prior art process was carried out at the distillation overhead at a temperature of 47.3° C. to obtain an overhead vapor stream (5) of the same composition and quality. The same applies to the method according to the invention. In the prior art distillation process, the temperature at the top of the distillation column is regulated by a reflux ratio of 0.26. In the process according to the invention, the temperature at the top of the distillation column (4) is adjusted by adjusting the proportion of the second liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com