Preparation method of changtongshu granules

A granule and formula technology, applied in the field of medicine, can solve the problems of inconsistent granule color, difficult spray drying granulation process, etc., and achieve the effect of improving normal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

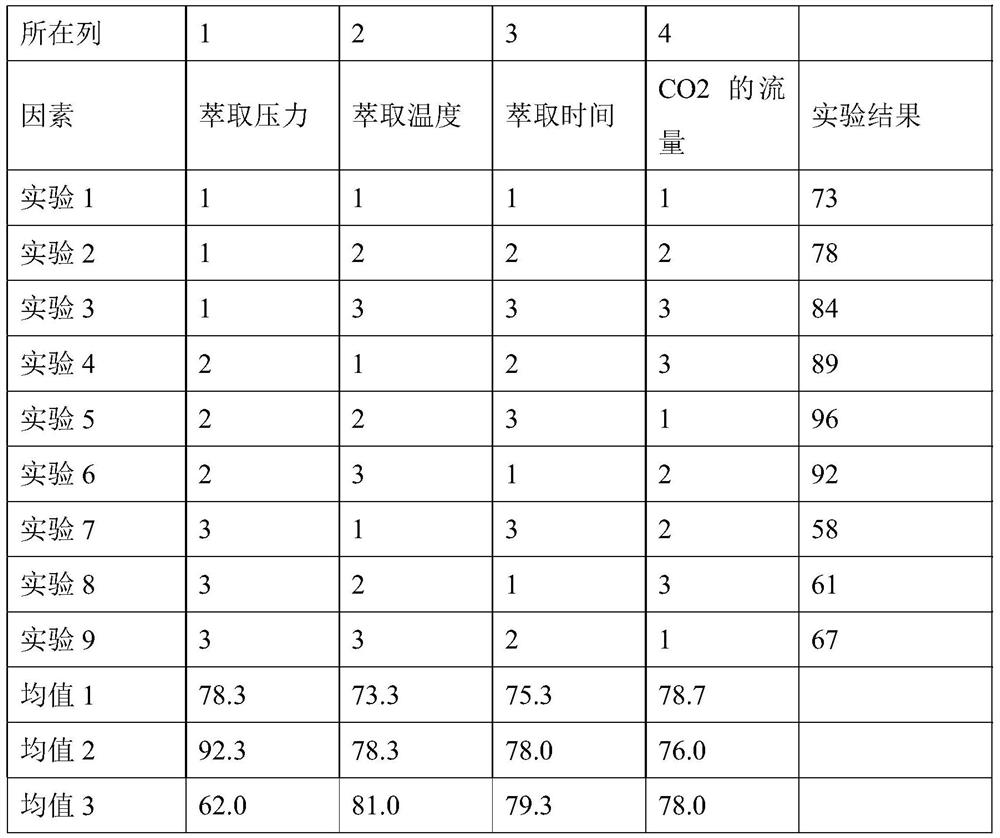

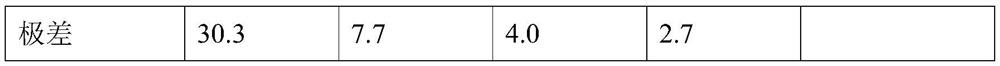

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1: 1250 parts by weight of Polygonum multiflorum, 833 parts by weight of Angelica sinensis, 833 parts by weight of Radix Paeoniae Rubra, 833 parts by weight of hemp seed, and 833 parts by weight of mulberry fruit, the steps are as follows: supercritical fluid extraction technology, extraction pressure 25Mpa, extraction temperature 35 degrees, The extraction time is 1 hour, and the flow rate of CO2 is 20 kg / hour. The extract is centrifuged, and the centrifugation parameters are as follows: the liquid temperature is 75-90°C, the centrifugal speed is 6900r / min, and the feeding speed is 2.0m3 / h. The centrifugate was concentrated to a relative density of 1.08 (60-70°C). After cooling to room temperature, add an equal amount of ethanol, stir well, let stand, take the supernatant and concentrate it into a clear paste with a relative density of 1.15-1.20 (60-70°C). Vacuum belt drying, vacuum belt drying parameters: heating system temperature 95°C in zone 1, 90°C in ...

Embodiment 2

[0075] Embodiment 2: 1250 parts by weight of Polygonum multiflorum, 833 parts by weight of Angelica sinensis, 833 parts by weight of Radix Paeoniae Rubra, 833 parts by weight of hemp seed, and 833 parts by weight of mulberry fruit, the steps are as follows: supercritical fluid extraction technology, extraction pressure 25Mpa, extraction temperature 35 degrees, The extraction time is 1 hour, and the flow rate of CO2 is 20 kg / hour. The extract is centrifuged, and the centrifugation parameters are as follows: the liquid temperature is 75-90°C, the centrifugal speed is 6900r / min, and the feeding speed is 2.0m3 / h. The centrifugate was concentrated to a relative density of 1.08 (60-70°C). After cooling to room temperature, add an equal amount of ethanol, stir well, let stand, take the supernatant and concentrate it into a clear paste with a relative density of 1.15-1.20 (60-70°C). Vacuum belt drying, vacuum belt drying parameters: heating system temperature 95°C in zone 1, 90°C in ...

Embodiment 3

[0076] Embodiment 3: Polygonum multiflorum 1250 parts by weight, Angelica 833 parts by weight, Radix Paeoniae Rubra 833 parts by weight, Hemp seed 833 parts by weight, Mulberry fruit 833 parts by weight, the steps are as follows: supercritical fluid extraction technology, extraction pressure 25Mpa, extraction temperature 35 degrees, The extraction time is 1 hour, and the flow rate of CO2 is 25 kg / hour. The extract is centrifuged, and the centrifugation parameters are as follows: the liquid temperature is 75-90°C, the centrifugal speed is 6900r / min, and the feeding speed is 2.0m3 / h. The centrifugate was concentrated to a relative density of 1.08 (60-70°C). After cooling to room temperature, add an equal amount of ethanol, stir well, let stand, take the supernatant and concentrate it into a clear paste with a relative density of 1.15-1.20 (60-70°C). Vacuum belt drying, vacuum belt drying parameters: heating system temperature 95°C in zone 1, 90°C in zone 2, 75°C in zone 3, 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com