Mixed acid nitration synthesis continuous production process and device

A mixed acid, continuous technology, applied in the direction of ammonia compounds, feeding devices, chemical/physical/physicochemical processes, etc., can solve the problems of polynitrates and oxidation, prone to combustion, explosion, small size of micro-reaction channels, etc. Achieve the effects of simple process flow, large heat release and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

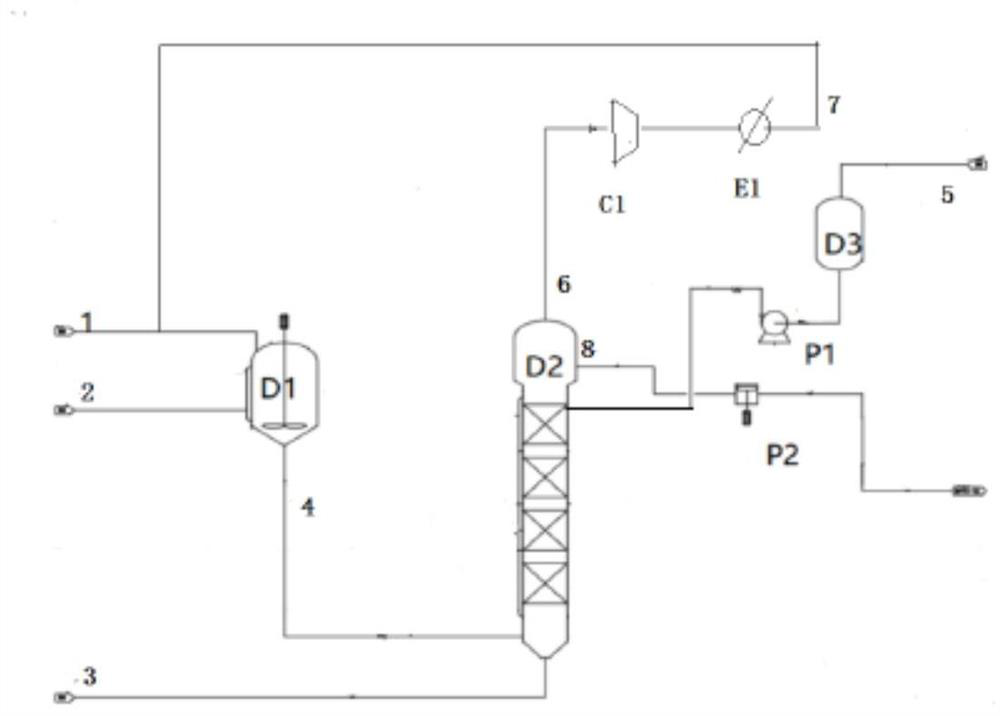

[0022] O-methyl-N-nitroisourea 30kg and 100kg of CO 2 The liquid is mixed in the mixing tank, the temperature of the mixing tank is 15°C, and the pressure is 5.2MPa; the mixed material enters the reactor continuously at a flow rate of 13kg / h, the temperature in the reactor is 15°C, and the pressure is 5.0MPa Mixed acid is added in the mixed acid storage tank by HNO3:H2SO4=3:1 (mol), and mixed acid enters into the reactor continuously with the flow rate of 9.6kg / h and reacts with ammonium sulfamate to generate ammonium dinitramide. CO 2 The gas continuously enters the bottom of the reactor at a flow rate of 8Nm3 / h as the power of the reactor. The generated ammonium dinitramide and unreacted mixed acid are continuously extracted from the upper part of the reactor with a flow rate of 12.6kg / h by the product discharge pump; the unreacted CO 2 The discharge from the top of the reactor is compressed and condensed into CO by the compressor and condenser 2 The liquid is returned to...

Embodiment 2

[0024] Ammonium sulfamate 9.7kg and 44kg of CO 2 The liquid is mixed in the mixing tank, the temperature of the mixing tank is -40°C, and the pressure is 1.2MPa; the mixed material enters the reactor continuously at a flow rate of 5.37kg / h, the temperature in the reactor is -40°C, and the pressure 1.0MPa; mixed acid according to HNO 3 :H 2 SO 4 =5:1 (mol) is added in the mixed acid storage tank, and the mixed acid continuously enters the reactor with a flow rate of 5kg / h to react with ammonium sulfamate to generate ammonium dinitramide. CO 2 The gas continuously enters the bottom of the reactor at a flow rate of 5Nm3 / h as the power of the reactor. The ammonium dinitramide and unreacted mixed acid are continuously extracted from the reactor top with a flow rate of 6kg / h by the product discharge pump; 2 The discharge from the top of the reactor is compressed and condensed into CO by the compressor and condenser 2 The liquid is returned to the ingredients tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com