Low-viscosity high-durability rapid curing duct piece concrete suitable for machine plastering

A concrete and viscous technology, which is applied in the field of low-viscosity, high-durability and quick-curing segment concrete, can solve the problems that the concrete cannot be machine-plastered, affects the progress of segment production, and takes a long time for segment forming and maintenance. It is not easy to segregate bleeding, improve the degree of mechanization, and the effect of short maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

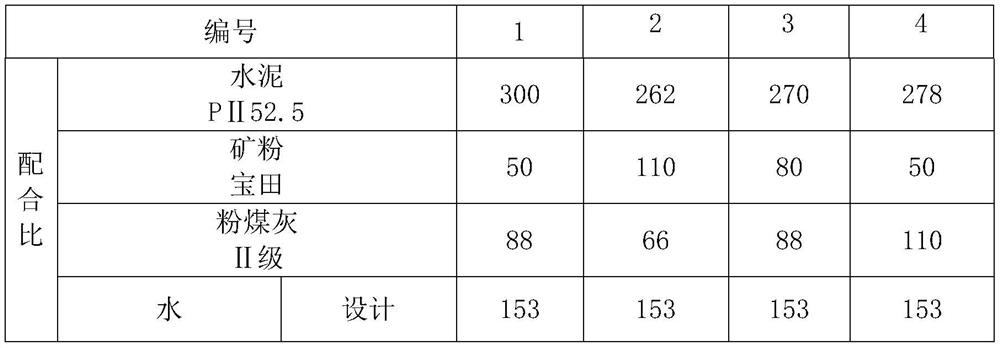

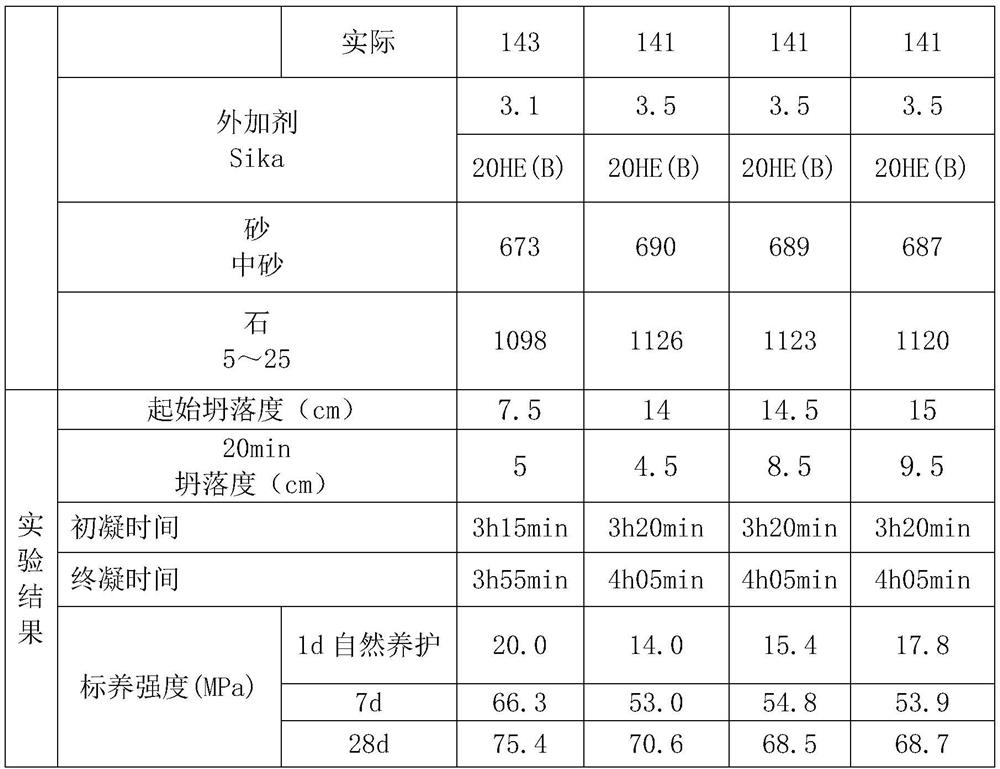

Embodiment 1

[0019] This embodiment provides a low-viscosity, high-durability and quick-curing segmental concrete suitable for machine plastering. The single-square concrete includes the following components: 300kg of cement, 50kg of mineral powder, 88kg of fly ash, and 673kg of fine aggregate , coarse aggregate 1098kg, mixing water 143kg.

Embodiment 2

[0021] This embodiment provides a low-viscosity, high-durability and fast-curing segmental concrete suitable for machine plastering. The single-square concrete includes the following components: 262kg of cement, 110kg of mineral powder, 66kg of fly ash, and 690kg of fine aggregate , coarse aggregate 1126kg, mixing water 141kg.

Embodiment 3

[0023] This embodiment provides a low-viscosity, high-durability and fast-curing segmental concrete suitable for machine plastering. The single-square concrete includes the following components: 270kg of cement, 80kg of mineral powder, 88kg of fly ash, and 689kg of fine aggregate , coarse aggregate 1123kg, mixing water 141kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com