Preparation method of high-specific-surface-area ceramic hollow spheres

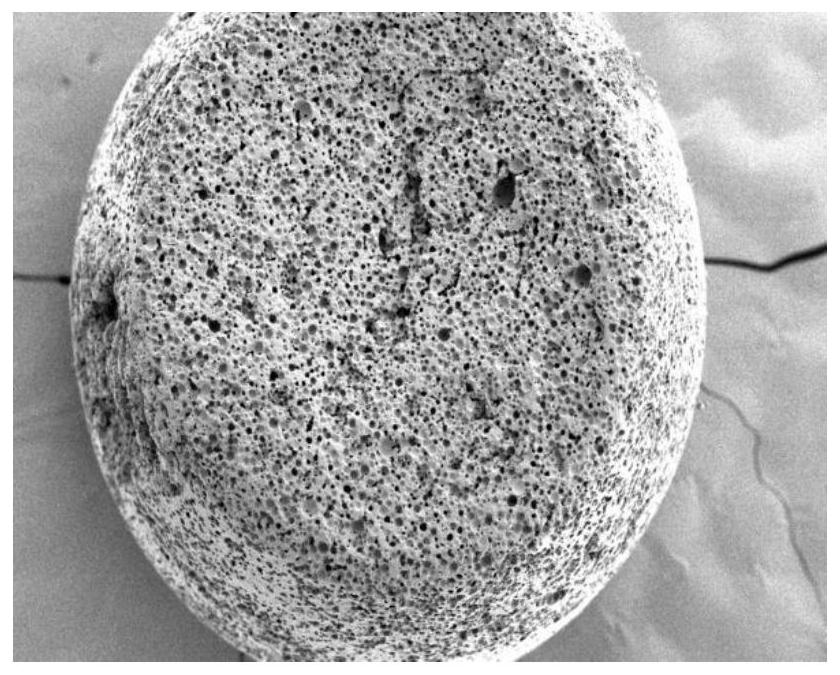

A technology of ceramic hollow spheres and high specific surface area, applied in ceramic products, applications, household appliances, etc., can solve problems such as poor use effect, and achieve the effect of better and smoother sphere surface, simple production process, and good application and promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

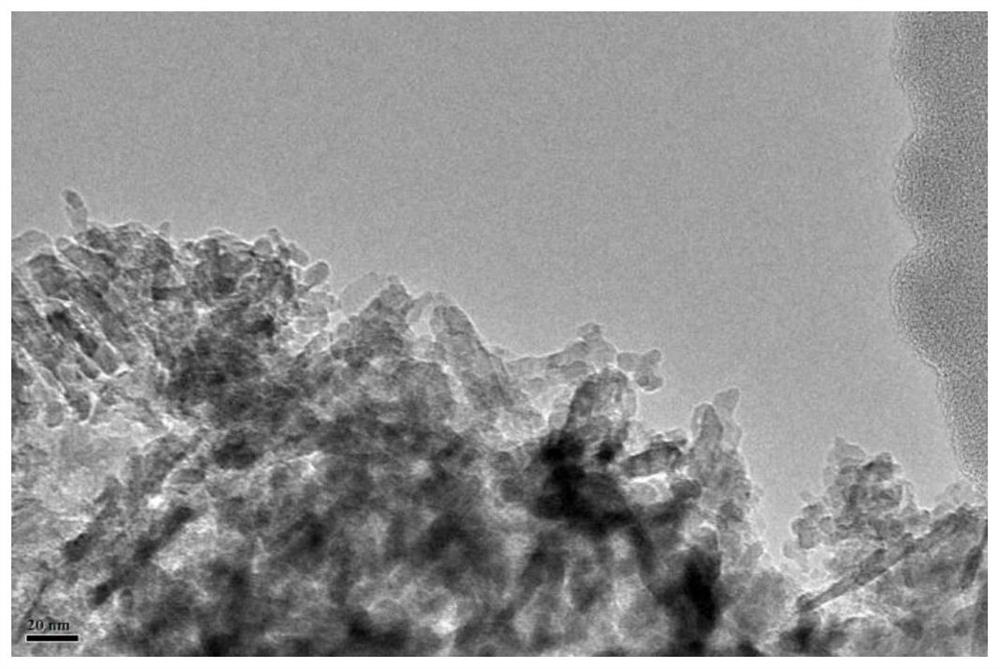

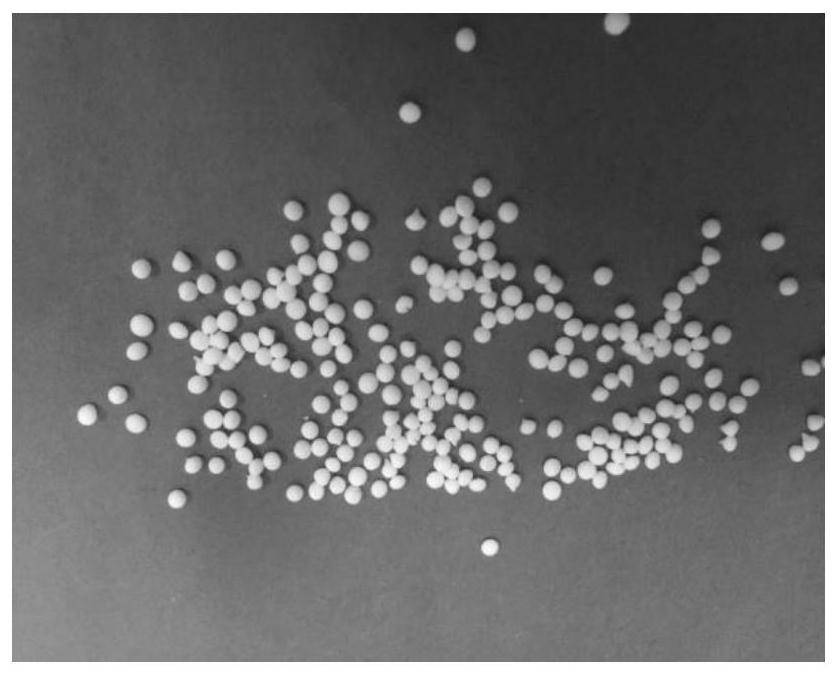

[0028] 1) Prepare a water-based slurry with a solid phase content of 30wt% using aluminum sol nanoparticles as a raw material;

[0029] 2) Adding short-chain amphiphile-modified particles with a specific gravity of 0.6 wt% of the sol suspension to the water-based slurry, adjusting the pH of the sol suspension to 3.8, so that the surface of the particles can be hydrophobically modified;

[0030] 3) mixing the prepared water-based slurry with octane, and stirring at a speed of 300rpm by a stirrer to obtain an ultra-stable microemulsion;

[0031] 4) Put the prepared microemulsion into a dropper, and add it dropwise to an alkaline solution with a pH of 10.5 to obtain gelled emulsion droplets. The publication number is CN102557594B Chinese invention patent for a high-strength low-density ceramic In the hollow sphere and its preparation method, carbon black, flour and water need to be mixed in a mass ratio of 3:5:2, mixed in a mud mixer, and then extruded in an extruder to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com