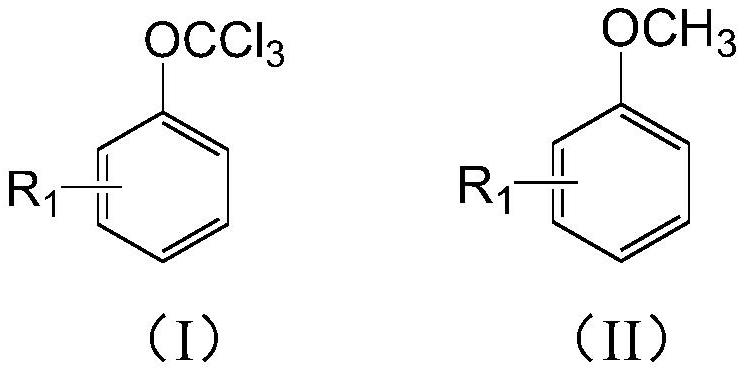

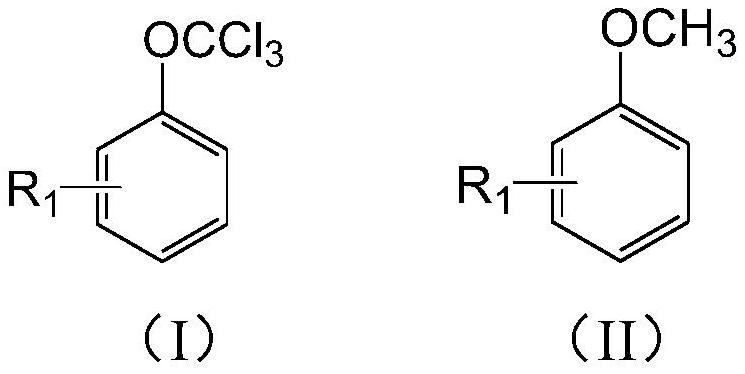

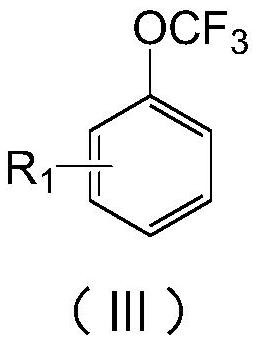

Preparation method of (trifluoromethoxy)benzene compound

A technology of trifluoromethoxybenzene and trichloromethoxybenzene, applied in the field of organic chemical industry synthesis, can solve problems such as solvent consumption, solvent cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] With 450g of fluorinated material rectification raffinate (main components: 4-chloro-trifluoromethoxybenzene 35.1%, difluoro-chloromethoxybenzene 20.4%, 4-chloro-difluoro-chloromethoxybenzene 15.7% %), 2.5g of phosphorus trichloride were added into a 1000mL reaction flask equipped with stirring, reflux condenser and chlorine pipe, and the temperature was raised to 120-130°C. Add 150g of anisole and 2.5g of AIBN, and at the same time feed chlorine gas to control the flow rate of chlorine gas to 40-50L / h. The reaction tail gas absorbs HCl therein through water, and then absorbs unreacted chlorine gas with 30% NaOH. After the anisole has been added, continue to feed chlorine, and add a mixed solution of 100g of fluorinated material rectification raffinate and 2g of AIBN. To the content of dichloromethoxybenzene in the reaction solution 2 Purging, precipitation, until the temperature of the kettle is 150°C / -0.096Mpa, the extracted solvent can continue to be used for the ch...

Embodiment 2

[0065] With 450g of fluorinated material rectification raffinate (main components: 20.2% of 4-chloro-trifluoromethoxybenzene, 35.8% of difluorochloromethoxybenzene, 16.7% of 4-chloro-difluorochloromethoxybenzene %), 2.5g of phosphorus trichloride were added into a 1000mL reaction flask equipped with stirring, reflux condenser and chlorine pipe, and the temperature was raised to 120-130°C. Add 150g of anisole and 2.5g of AIBN, and at the same time feed chlorine gas to control the flow rate of chlorine gas to 40-50L / h. The reaction tail gas absorbs HCl therein through water, and then absorbs unreacted chlorine gas with 30% NaOH. After the anisole has been added, continue to feed chlorine, and add a mixed solution of 100g of fluorinated material rectification raffinate and 2g of AIBN. To the content of dichloromethoxybenzene in the reaction solution 2 Purging, precipitation, until the temperature of the kettle is 150°C / -0.096Mpa, the extracted solvent can continue to be used for...

Embodiment 3

[0067] Add 600g of rectification raffinate of fluorinated materials (main components: 41% of 4-chloro-trifluoromethoxybenzene, 35% of 4-chloro-difluoro-chloromethoxybenzene) and 2.5g of phosphorus trichloride to 1000mL In a reaction flask equipped with stirring, a reflux condenser, and a chlorine pipe, the temperature is raised to 120-130°C. Add 200g of 4-chloroanisole and 2.5g of AIBN, and at the same time feed chlorine gas to control the flow rate of chlorine gas to 40-50L / h. The reaction tail gas absorbs HCl therein through water, and then absorbs unreacted chlorine gas with 30% NaOH. After adding 4-chloroanisole, continue to pass chlorine, and add the mixed solution of 100g rectification raffinate of fluorinated material and 2g AIBN. To the content of 4-chloro-dichloromethoxybenzene in the reaction solution 2 Purging, precipitation, until the temperature of the kettle is 150°C / -0.096Mpa, the extracted solvent can continue to be used for the chlorination reaction of 4-chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com