Water-based zinc-plating coating for refrigerated containers

A water-based technology for refrigerated containers, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as high VOC of cold-sprayed zinc, failure to meet the VOC emission standards of water-based coatings for containers, and solvent volatilization, etc., to achieve The effect of excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0039] A water-based galvanized coating for refrigerated containers, which is made by mixing two components A and B at a ratio of 5:1 by weight, wherein component A is wetted by deionized water, defoamer, dispersant, and substrate Agent, cellulose, water-based acrylic acid or water-based polyurethane, alcohol ester 12 compatibility, component B is composed of black flaky zinc powder, spherical zinc powder, zinc aluminum alloy powder, and silane coupling agent. The manufacturing method is:

[0040] (1) Put deionized water, defoamer, dispersant, substrate wetting agent, cellulose, water-based acrylic acid or water-based polyurethane, and alcohol ester 12 into the tank according to the weight ratio, and stir at 800 rpm 20 minutes, then grind all the materials through a grinder to a fineness of less than 20um, filter and pack through a 200-mesh filter to obtain component A of water-based galvanized paint;

[0041] (2) Mix the silane coupling agent with ethanol, add black flaky zin...

Embodiment A

[0043] See Table 1 for the selection and weight ratio of the raw materials of components A and B in each embodiment.

[0044]

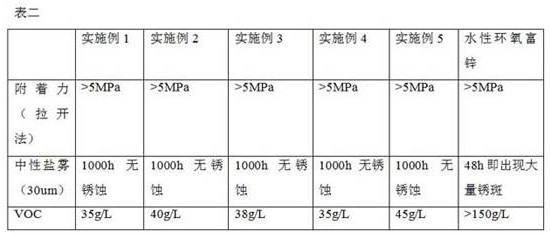

[0045] Examples 1-5 are water-based galvanized coatings of the present invention, and the technical indicators of the water-based water-based epoxy zinc-rich coating are compared in Table 2

[0046]

[0047] It can be seen that the anti-corrosion performance of the water-based galvanized coating is far superior to that of the current containerized water-based epoxy zinc-rich coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com