Light hydrocarbon recovery method and device

A light hydrocarbon recovery and absorbent technology, which is applied in the recovery of liquid hydrocarbon mixtures, chemical instruments and methods, and treatment of hydrocarbon oil, etc. Low, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

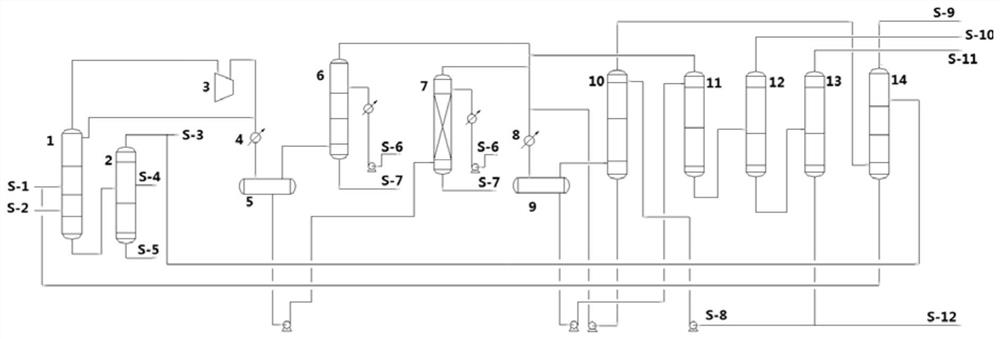

Embodiment 1

[0106] Light hydrocarbon recovery device, including: heat / cooling oil feed line, denal column 1, fractionation column 2, compressor 3, cooler 4, gas-liquid separation tank I5, rich gas desulfurization tower 6, liquid hydrocarbon demonstio Tower 7, reel 8, gas-liquid separation tank II, absorption tower 10, and separation unit;

[0107] Among them, the heat / cold low-filled oil feed line is connected to the depripane column 1;

[0108] The depene tower 1 is provided with a condenser and a reflow tank, a tower and a fractionation column 2, and the top of the column is sequentially connected to the condenser, the reflow tank, and the tank tank is sequentially and the rich gas desulfurization tower 6, the reel 8, gas The liquid separation tank II9 is connected, the bottom is sequentially with the liquid hydrocarbon 1. The recess 8, the gas-liquid separation tank II9 is connected;

[0109] The gas-liquid separation tank II9 can top is connected to the absorption tower 10, and th...

Embodiment 2

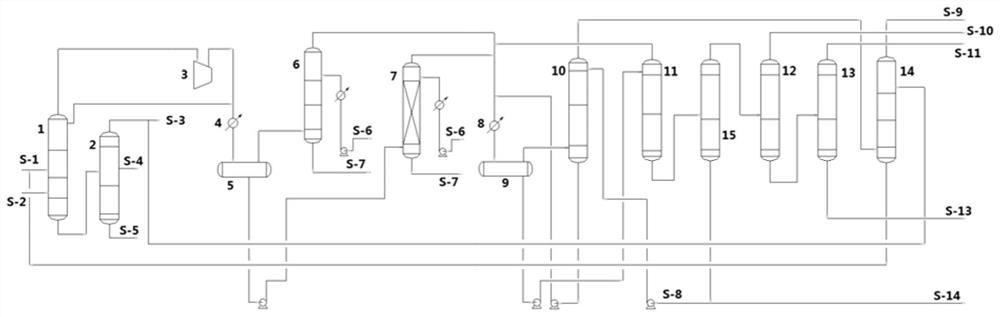

[0139] Use figure 2 The process flow diagram shows oil and gas desulfurization and the recovery of light hydrocarbons.

[0140] Among them, the difference between the present embodiment and the first embodiment is:

[0141] (7) Separation:

[0142] Demethyl: The liquid phase from the gas-liquid separation tank II9 can remove methane in the demethhane tower 11, while removing components of less C2 and C2 or more, the dehydrin tower 11 tower is closed after cooling. The gas-liquid separation tank II9, the tower is delivered to the decene butterore 15; the operation temperature of the demethhane tower 11 tower is 15 to 40 ° C, the operating pressure is 2.25 ~ 2.85 MpAg;

[0143]Dytanone: The liquid phase from the bottom of the demethhane tower 11 is separated from the component of C3 and C3 below the deceanent tower 15, and the separated tower is delivered to the dehydrophane tower 12, the bottom liquid phase At least a portion was sent to the absorbent tower 10 as a mixed C4 absorb...

Embodiment 3

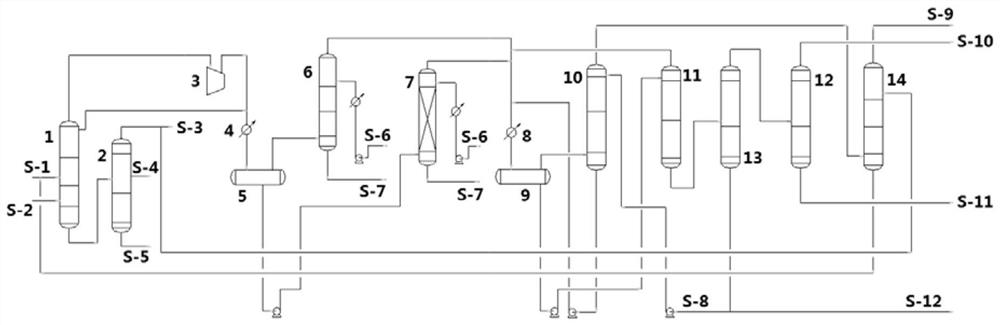

[0156] Use image 3 The process flow diagram shows oil and gas desulfurization and the recovery of light hydrocarbons.

[0157] Among them, the difference between the present embodiment and the first embodiment is:

[0158] (7) Separation:

[0159] Demethyl: The liquid phase from the gas-liquid separation tank II9 can remove methane in the demethhane tower 11, while removing components of less C2 and C2 or more, the dehydrin tower 11 tower is closed after cooling. The gas-liquid separation tank II9, the bottom of the tower is delivered to the propylphane tower I13; the operating temperature of the demetaxane tower 11 tower is 15 to 40 ° C, the operating pressure is 2.25 ~ 2.85 MpAg;

[0160] Phane: The liquid phase components from the bottom of the demethhane tower 11 were separated in the delxtin column I13, and the components of the separated C3 and C3 were removed from the top of the propylpane column I13 column. 12, at least a portion of the bottom component is sent to the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com