High-steel-grade oil well pipe and preparation method thereof

An oil well pipe and steel grade technology, which is applied in the field of high steel grade oil well pipe and its preparation, can solve the problems of long heat treatment process time, high manufacturing cost of oil well pipe, complicated process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a high-grade steel oil well pipe, comprising the following steps:

[0040] Step 1. Smelting, refining and continuous casting are carried out according to the composition of the oil well pipe to form a slab; the slab is heated at a heating temperature of 1180-1220° C.; heat preservation is carried out for 1-1.5 hours.

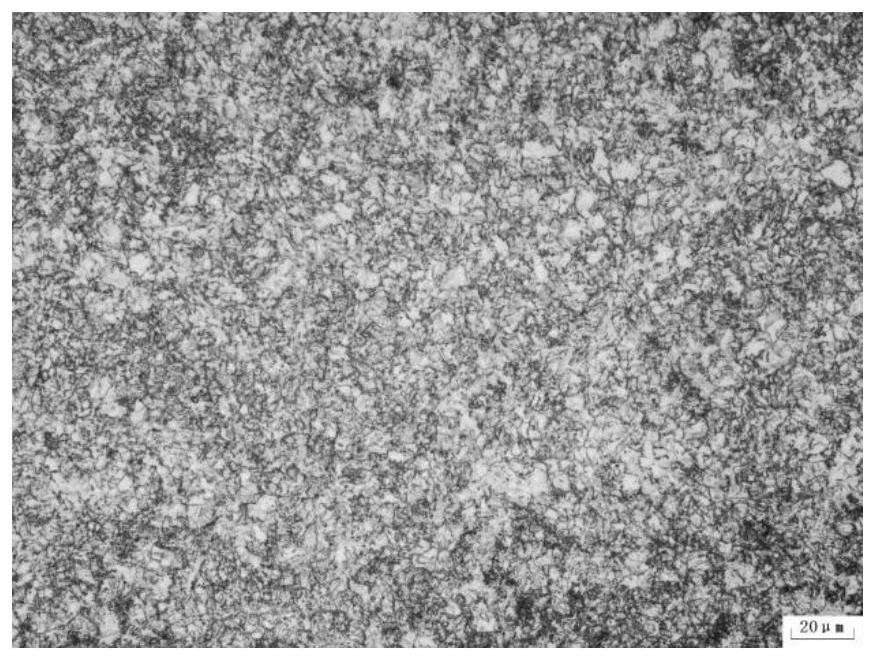

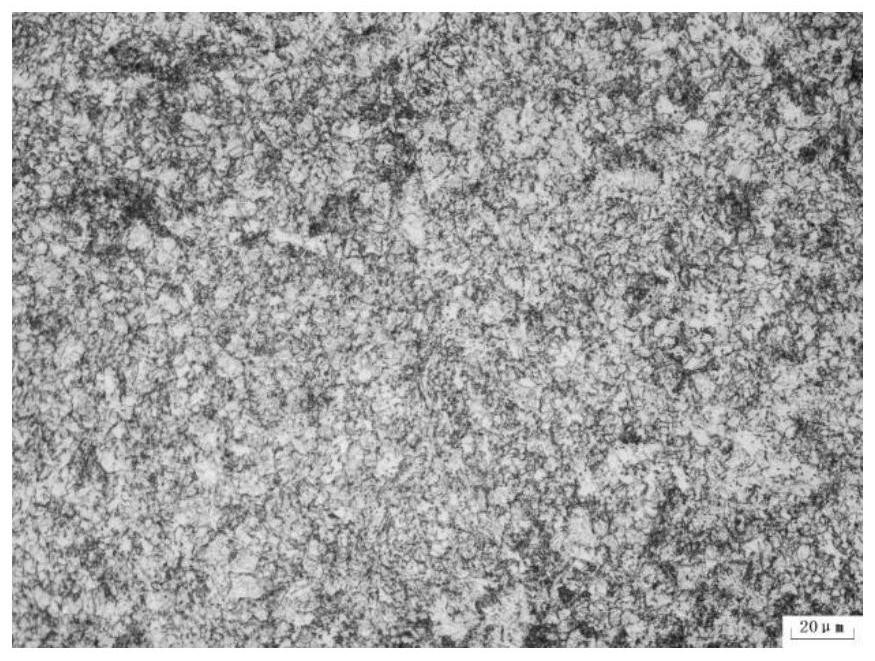

[0041] Step 2. The cast slab after heat preservation is directly pierced, descaled, continuously rolled, sized, and air-cooled to room temperature to obtain a hot-rolled steel pipe; wherein, the final rolling temperature of the continuous rolling process is controlled at 820-860°C to ensure that the hot-rolled steel pipe The microstructure is granular bainite.

[0042] Step 3. Inductively heat the hot-rolled steel pipe to the temperature T1 (for example, 780-820°C) between the two-phase regions, keep it warm for 10-30s, cool it to T2 (400-450°C) in air, then quench it in a salt bath to room temperature, and then return to Fire gets...

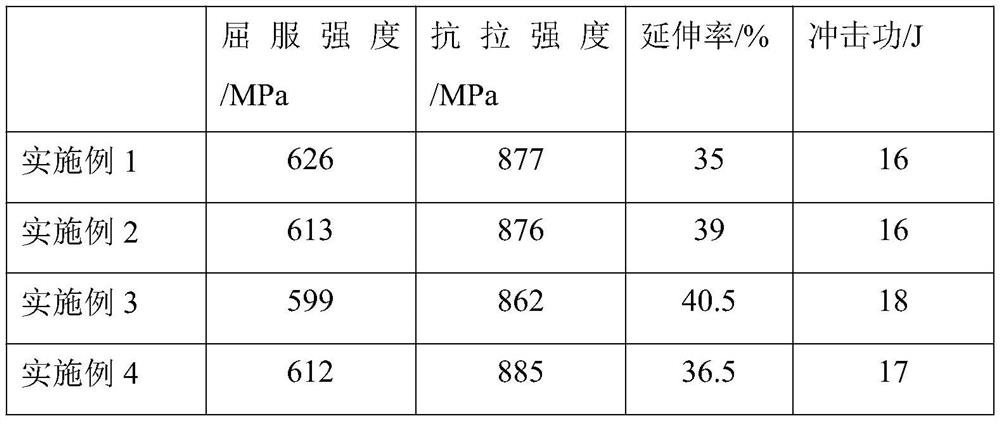

Embodiment 1

[0055] This embodiment provides a high-grade oil well pipe, which is prepared by the following method:

[0056] Step 1. Smelting, refining and continuous casting are carried out according to the composition of the oil well pipe to form a slab; the slab is heated at a temperature of 1180° C. and kept for 1 hour.

[0057] Step 2. The cast slab after heat preservation is directly pierced, descaled, continuously rolled, sized, and air-cooled to room temperature to obtain a hot-rolled steel pipe; wherein, the final rolling temperature of the continuous rolling process is controlled at 820°C to ensure the microscopic quality of the hot-rolled steel pipe. The organization is granular bainite.

[0058] Step 3. Inductively heat the hot-rolled steel pipe to 780°C, keep it warm for 30s, air cool it to 400°C, then quench it in a salt bath to room temperature, then keep it at 500°C for 1 hour, then air cool it to room temperature to obtain a high-strength steel grade oil well pipe.

Embodiment 2

[0060] This embodiment provides a high-grade oil well pipe, which is prepared by the following method:

[0061] Step 1. Smelting, refining and continuous casting are carried out according to the composition of the oil well pipe to form a slab; the slab is heated at 1200° C.; and kept for 1.5 hours.

[0062] Step 2. The cast slab after heat preservation is directly pierced, descaled, continuously rolled, sized, and air-cooled to room temperature to obtain a hot-rolled steel pipe; wherein, the final rolling temperature of the continuous rolling process is controlled at 840°C to ensure the microscopic quality of the hot-rolled steel pipe. The organization is granular bainite.

[0063] Step 3. Inductively heat the hot-rolled steel pipe to 780°C, keep it warm for 20s, air cool it to 450°C, then quench it in a salt bath to room temperature, then keep it at 500°C for 1 hour, then air cool it to room temperature to obtain a high-strength steel grade oil well pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com